15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

128 |

Published by VMT at Jun 08 2022

128 |

Published by VMT at Jun 08 2022

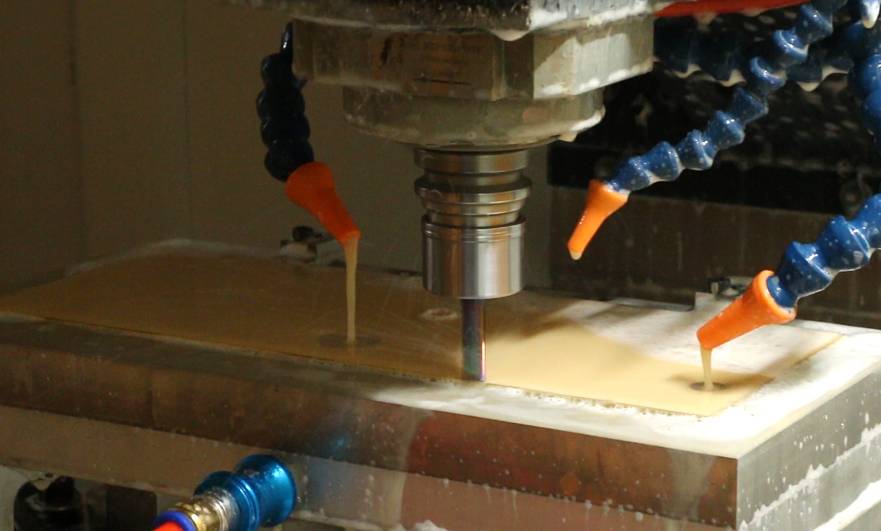

CNC prototype machining is the first step to verify the feasibility of the product, and it is the most direct and effective way to find out the defects, deficiencies and drawbacks of the designed product, so as to improve the defects in a targeted manner. Especially for the development of new products, it can save expensive mold opening costs, reduce research and development risks, and speed up research and development efficiency. So, what are the benefits of small batch CNC prototyping machining?

Benefit 1: To verify the appearance, just look at the picture. If there is no physical object, the product cannot be verified intuitively, and the customer does not accept it. The customer needs a physical product that can be held in his hand.

Benefit 2: Verify the function, according to the functional test case, test item by item to check whether the CNC machined parts meet the functions required by the user.

Benefit 3: Participating in the exhibition, when there is no product, you can use CNC prototype machining parts to replace the product to display at the exhibition, do a good job in the early publicity work, and even get orders.

Benefit 4. Direct sales, such as structural prototypes, also called functional prototypes, can be directly sold as products in the market. There is also a small batch of CNC prototype machining parts, which can be directly sold, which can verify the market's response to the product.

Benefit 5: Cost reduction, CNC prototype machining parts are generally not perfect after design, or even unusable. If they are directly produced, once they are defective, they will all be scrapped, greatly wasting manpower, material resources and time, and the loss is comparable to CNC prototype machining costs. Because the prototype is generally a small number of samples, the CNC machining production cycle is short, and the loss of manpower and material resources is small, and the deficiencies in the design of CNC prototype machining parts can be quickly found and improved, providing sufficient basis for product finalization and mass production.

VMT has 13 years of experience in CNC prototype machining and production, and can provide customers with one-stop service from prototype processing design to prototype verification, mold manufacturing to CNC prototype machining and small batch production, saving you costs and shortening the development cycle of new products.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!