15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

117 |

Published by VMT at Dec 07 2021

117 |

Published by VMT at Dec 07 2021

For those who specialize in product production, CNC machining rapid prototyping should be a fixed term in your industry. This is because most CNC machining manufacturers often use prototyping techniques to determine what the final design of their products will look like or feel.

When a product team is developing a new CNC machining component or feature, CNC machining prototype development is a low-risk method for exploring and validating ideas. Although the CNC machining prototype stage is famous for testing and innovation, the methods behind CNC machining rapid prototyping accelerate this process.

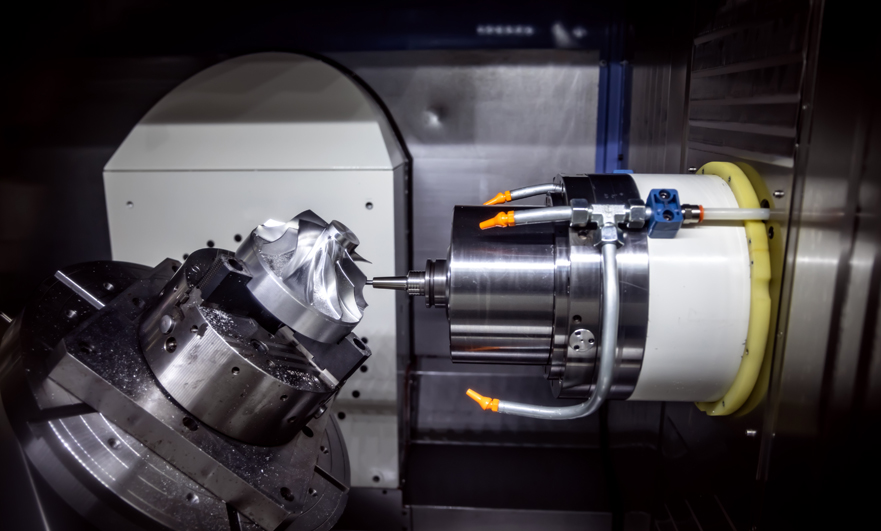

CNC machining rapid prototyping is the use of computer-aided design (CAD) software to quickly manufacture physical parts, models or assemblies. When it comes to actual design, this step is performed using an additional manufacturing process-namely 3D printing. Other technologies include high-speed machining, casting, forming, and extrusion. The main goal of CNC machining rapid prototyping is to obtain effective insights and user feedback as early as possible in order to improve the design until all needs are met.

Advantages of using CNC machining rapid prototyping in your business

1. Production speed

CNC machining rapid prototyping technology allows you to design and test parts in a shortened time frame. This allows you to have a comprehensive model preparation to determine if all requirements have been met or if more adjustments are needed. If all the standards are met, then the design can be approved and full production can begin. However, if there are defects in prototype CNC machining rapid prototyping, rapid prototyping allows you to design, develop, and test new design iterations in a shorter turnaround time than traditional prototypes allow.

2. Reduce costs

Among all the forms of CNC machining rapid prototyping manufacturing, rapid prototyping has always been considered the most cost-effective method. This is because the parts are in low volume and each prototype is much cheaper than any final production model that may produce the process of. This allows you to test products with minimal financial risk-keeping your production on budget.

3. Product development concept

CNC machining rapid prototyping allows you to quickly and effectively transform your concept into a test subject.

4. Comprehensive model for approval

Based on your business model, CNC machining rapid prototyping development allows you to send the physical model to the customer and management team for approval. In addition to allowing them to make specific observations of the project in a way that is rarely seen, these prototypes can also help the team determine the feasibility, effectiveness and acceptance of the market before completing the production order. Then, feedback from the team can help improve the final design.

As you can see, the benefits of CNC machining rapid prototyping are huge. This process not only allows early visibility of the project, but also allows any defects and issues to be quickly identified and corrected at low cost. In addition, active communication between the parties will lead to greater results and delivery of higher quality parts or models. Rapid prototyping is a critical process for engineers, which is why we regard it as the core of VMT CNC machining services. If you want to speed up your CNC machining rapid prototyping manufacturing process, please contact us.

5. Allow functional testing

Your CNC machining rapid prototyping accurately reflects the appearance and operation of your product. Testing and retesting provide opportunities for fine-tuning your ideas and turning them into successful designs that are most likely to succeed. Can it provide a good user experience? Can it achieve your goals? At this point, you can discover features that require more work and identify potential areas for expansion.

6. Ergonomic evaluation and identification of product hazards

CNC machining rapid prototyping design allows product designers to identify potential product safety and/or compliance issues. From one form to another function, at this stage you can find the source of any risk factors involved in the design. A large number of materials are used in the rapid prototyping process of CNC machining, making it easy for you to find the ideal combination to ensure that your final product achieves your goals.

If you have reached this point, then we assume that you have passed this guide and learned different methods. CNC machining rapid prototyping can be a huge help for you.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!