15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

332 |

Published by VMT at Aug 16 2023

332 |

Published by VMT at Aug 16 2023

In the fast-paced world of smartwatches, a case is more than just a case, it's an expression of style and innovation. From gleaming metal finishes to sleek ceramic designs, each smartwatch case is the result of meticulous manufacturing techniques. In this article, we take you on a journey into the fascinating world of smartwatch casing production, exploring the methods, benefits and factors that influence the choices of manufacturers and consumers.

Multiple Manufacturing Techniques for Smart Watch Cases

The machining technology of the smart watch case is similar to that of the traditional watch case, and the following processes can be used:

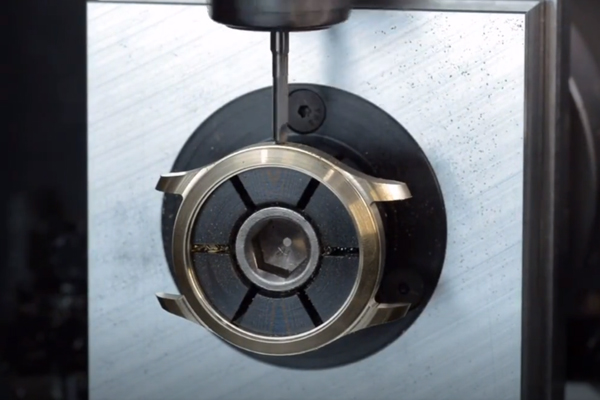

CNC Machining: Redefining Precision

One of the most prominent technologies in the production of smart watch cases is computer numerical control (CNC) machining. This high-precision method involves computer-guided tools that meticulously carve and shape raw materials such as metal or plastic into the desired enclosure design. The result is a case that fits perfectly with the smartwatch components, ensuring a seamless and precise finish.

CNC Machining (Numerical Control Machine Tool Machining): CNC machining is a method of automated machining through a numerically controlled machine tool. It can achieve high precision and complex shape machining, and is suitable for various materials, including metals and plastics. Operations such as cutting, engraving and drilling can be performed according to design requirements to produce precise shell shapes.

The advantages of CNC machining are high precision, stable machining quality, and the ability to achieve complex designs and details. However, the price of CNC machining is relatively high.

Injection Molding: Efficiency and Versatility

Injection molding is a popular choice for those looking for efficiency and versatility. The process involves injecting molten material, usually plastic, into a mold to form the shell. Injection molding enables complex designs, consistent shapes, and rapid production, making it an attractive option for manufacturing a variety of smartwatch casings. Injection molding allows efficient mass production at relatively low cost. It is suitable for the machining of plastic CNC watch cases, and plastic materials of different colors and textures can be selected according to design requirements.

Ceramic Compression: Elegant and Durable

The ceramic case embodies the combination of elegance and durability. Through ceramic compression, ceramic powder is subjected to high pressure and heat to form a shell that is both scratch-resistant and visually striking. This technology is favored for its ability to produce stylish, sophisticated casings with a premium feel.

Ceramic forming is a process of working with ceramic materials. Ceramic watch cases have high hardness, scratch resistance and corrosion resistance. It can also achieve designs in various colors and textures. However, the price of ceramic molding is relatively high, and the machining process is also relatively complicated. Designs in various colors and textures can be realized.

Investment Casting

Investment casting is a process in which metal is melted and poured into a mold, allowing it to solidify into the desired shape. It can realize complex designs and details, and is suitable for the machining of metal CNC watch cases. Intricate designs and details can be achieved. Different metal materials can be used, such as stainless steel, aluminum alloy or titanium alloy.The advantage of investment casting is that it can produce high-quality metal casings with high durability.

Sintering of Metal Case

The metal casings typically associated with high-end smartwatches are produced through a process called sintering. The metal powder is compacted and heated to fuse the particles together to form a strong, resilient, surface-polished shell.

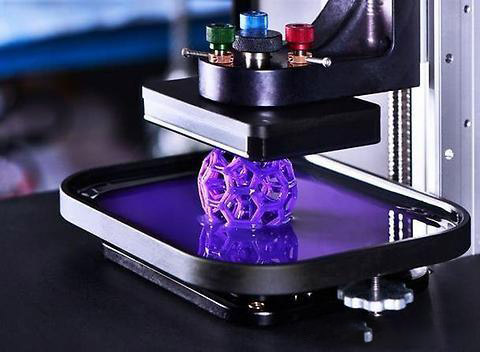

Advanced 3D printing

3D printing has found its way into smartwatch casings, enabling the creation of intricate and customizable designs. The technology allows manufacturers to experiment with various shapes and materials while reducing waste. Using 3D printing technology can directly transform design files into physical products. Different types of 3D printers and materials such as plastic, metal or ceramic can be used to create watch cases. 3D printing enables complex geometries and individual designs.

These machining techniques can be selected according to the design requirements and budget to produce parts that meet the requirements of your smart CNC watch case.

CNC Watch Case Price

In terms of price, generally speaking, injection molding is a relatively cheap option, while precision casting and ceramic molding are more expensive.

As for machining speed, CNC machining is usually the fastest because it allows for automation and high-speed cutting. The machining speed of injection molding and precision casting is relatively slow, and the machining speed of ceramic molding is also slow and complicated.

It should be noted that the specific machining speed and price may be affected by many factors, including the design complexity of the CNC watch case, material selection, and the equipment and process level of the CNC machining factory. Therefore, when choosing a CNC machining process, it is best to make comprehensive considerations based on specific needs and budgets.

Advantages of Different CNC Machining Manufacturing Technologies

Precision and Customization

CNC machining provides unparalleled precision, ensuring that every detail of the case is crafted to perfection. Injection molding, on the other hand, excels at creating complex designs with consistent quality. Ceramic compression strikes a balance between elegance and sturdiness, making it ideal for those looking for a stylish yet durable smartwatch case.

Efficiency and Speed

Injection molding has efficient production and quick turnaround times, making it a cost-effective option for mass production. CNC machining provides precision at slightly slower speeds, while ceramic compression provides a balance between production speed and housing quality.

Precautions for Smart Digital Watch Manufacturers and Consumers

When choosing a smart CNC watch case machining and manufacturing technology, there are several factors to consider. Budget, required design complexity and speed of production are key considerations. For example, large manufacturers often choose injection molding to efficiently meet demand. Smaller boutique brands may gravitate toward CNC machining for its precision and customization options.

Ultimately, the choice of manufacturing technique depends on the proper balance of cost, design, and speed of production to provide a smartwatch case that meets both style and functional expectations.

Elevate Style and Function

The combination of these manufacturing techniques and cutting-edge technology makes for smart watch cases that are not only visually appealing, but functional as well. These enclosures provide vital protection for internal components, ensuring durability and longevity.

Smartwatch cases also offer opportunities for personalization, allowing users to choose from a variety of materials, colors and finishes to match their style preferences. Whether you prefer a sleek, modern look or a classic and elegant look, there are case options to suit every taste.

Conclusion: The Fusion of Art and Innovation

When you adorn your wrist with a stylish smartwatch, remember that its case is a masterpiece of engineering and design. The fusion of traditional craftsmanship and modern technology makes the case not only an accessory, but also a reflection of your personality.

Whether it's the precision of CNC machining, the artistry of ceramic compression or the versatility of 3D printing, each manufacturing technique plays a key role in creating smartwatch casings that complement your lifestyle and enhance your technology experience.

In the world of smartwatch casings, innovation is limited only by imagination. Embracing the integration of craftsmanship and technology, elevating smart watches from mere accessories to symbols of individuality and innovation.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!