15 years one-stop China custom CNC machining parts factory

283 |

Published by VMT at May 12 2022

283 |

Published by VMT at May 12 2022

When it comes to high precision, excellent processing accuracy, and reliable machining option, then predominantly CNC machining services this purpose most effectively and comprehensively. Computer numerical control machining comes amongst the most efficient and errorless machining processes. Along with its numerous characteristics, it offers a large category of materials to be machined such as plastic.

If you are looking for in-depth knowledge about plastic CNC machining then it’s a must-read piece of writing for you. And it is highly recommended that you read till the end. In this article, you will be thoroughly elaborated on the role of plastic in CNC machining, and its applications in different industries. Also, the advantages and limitations of plastic CNC machining will be discussed. In the end, numerous different plastic types and their prominent attributes will also be discussed.

Plastic CNC machining offers manufacturing of very similar parts to series parts. For low-volume plastic parts manufacturing, the production process is often very faster and more efficient as compared to the other rapid prototyping technologies. Generally, the plastic CNC process is considered preferable when the manufacturing quantity of plastic prototypes lay between 1 and 10 parts and sizes greater than 600 mm.

How is CNC machining of plastics used in different industries?

Many different industries use plastic CNC machining services due to their efficiency and durability. These CNC parts that require plastic manufacturing can also be used in the manufacturing of plastic toys in their different equipment and machine applications. Industries that use these services are as follows.

The crucial industries like aerospace where the tiniest mistake may lead to catastrophic outcomes. That will not only cause losing a great amount of money but precious human lives too. Therefore, after finalizing a part and rather directly fixing it into hefty airplanes, it is preferred to pre-judge the durability of the part. To do so, a prototype of the part is manufactured using plastic CNC machining.

This advanced prototyping technology offers a great deal to check the durability of the parts. So, any disastrous happening can be avoided due to an error in the parts. Apart from manufacturing plastic prototypes, different aircraft parts like fuselages, rudders, ventilation ducts, etc., are also manufactured using the plastic CNC machining.

Military and defense industries rely on plastic CNC machining for the production of their numerous important plastic parts. These plastic parts offer great durability and serve as prototypes for the testing of complex designs. From the manufacturing of the parts to be used in their communication devices to parts fixing in their vehicles, plastic CNC machining plays a vital role in the military and defense industry.

The medical industry requires the production of some specialized equipment to be used to carry out some critical processes and in the manufacturing of different medicines. Some categories of plastic offer these special properties required in the manufacturing of this equipment and machines.

As the medical field is evolving expeditiously and the demand for new equipment is also rising. But some equipment requires a high level of purity, safety, and sterilization. This means the equipment will be exposed to extreme levels of sterilization regularly. So, to meet this demand, certain plastic types are found highly suitable. Other than this, medical equipment like sterilization trays, surgical equipment, imaging equipment, etc. is made using plastic CNC process.

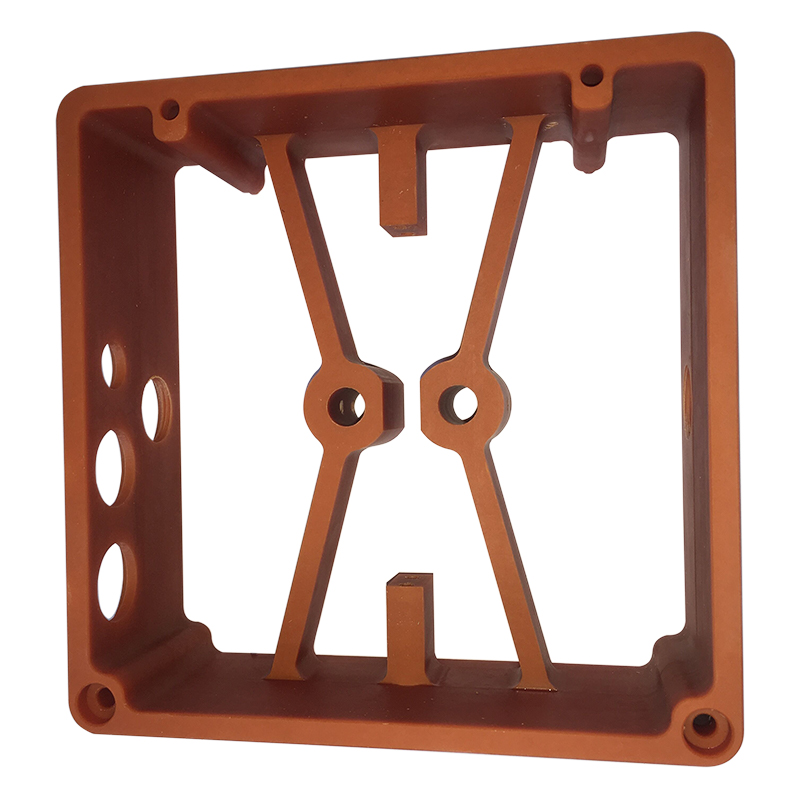

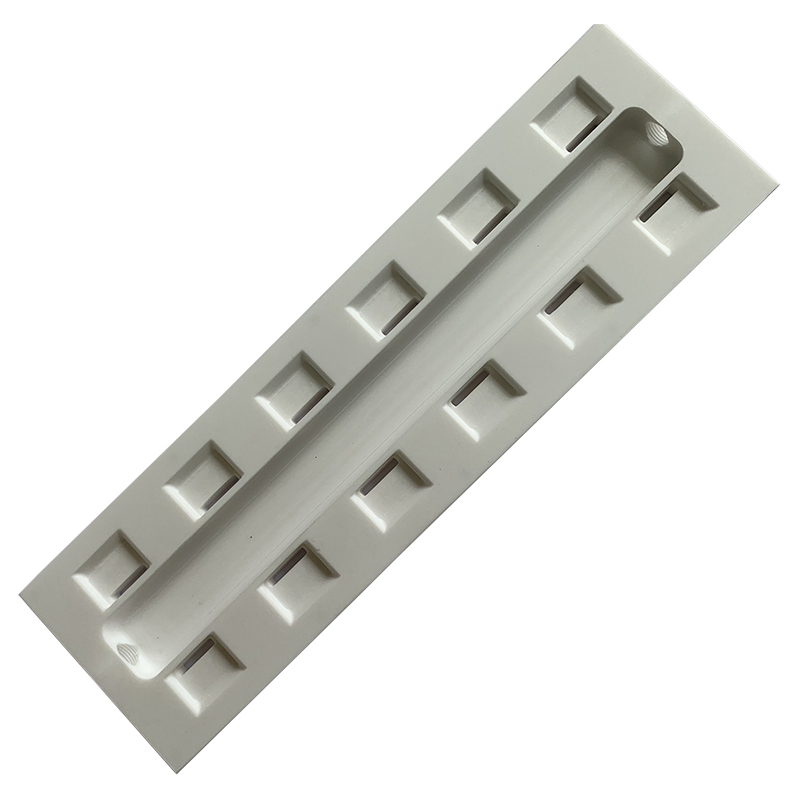

Plastic CNC machining is extensively used in the manufacturing of many electronic devices. These devices require efficient plastic components that comprise a complex electronic product. Electronic devices such as circuit breakers, switchgear, lighting fixtures, electrical components, telephone handsets, keyboards, monitors, computer housings, etc. are manufactured using plastic CNC machined.

Advantages of Plastic CNC Machining

There are several reasons why you should prefer plastic for your part manufacturing. It depends on your product requirements when to choose this technology. But if your requirements are fulfilled using other technologies than the plastic CNC machining, but why you still rely on this technology? So, numerous advantages make using plastic a wise choice for your product manufacturing and are discussed below.

Creating prototypes to test the efficiency and durability of your part design before going into mass production. It saves a lot of time, money, and helps in maintaining project schedules. But when it comes to a faster and economical prototyping process, then plastic CNC machining is the best choice. The reason being, creating a prototype using this technology does not require any mold making. That offers faster prototype turnarounds.

When it comes to manufacturing high-precision parts, then such machining technologies and materials are preferred that offer higher tolerances. Because higher tolerances are one of the key factors that ensure high-precision part productions. So, the plastic CNC machining process offers outstanding higher tolerances. And is used in many crucial industries for the production of high-precision parts.

The plastic CNC machining process is comparatively economical. Because it does not require any extra money and time to be wasted on making the molds for the products to be manufactured. For example, if you choose injection molding for your part production then be ready to spend more resources than the plastic CNC process on mold generation.

The parts manufactured using plastic than the ones that are made of metal materials have the advantage of not being rusted. Because plastic material generally offers greater resistance to corrosion and chemicals.

Preferred Use of Plastic CNC Machining

Sometimes, it becomes hard to decide whether plastic CNC machining will do the business efficiently for what it is intended to fulfill. Now, the question arises, how will you come to know? So, don’t worry! If your production requirements meet the following criteria then it's good to go with plastic CNC technology.

If you think that you fall in any of the above-mentioned categories or are confused about making the right decision then don’t worry. You can contact us. We can guide you in the best possible way to maximize your productivity.

Common Types of Plastics in Use

There are many types of plastics that machinists utilize in plastic CNC machining. The selection of a particular material depends on the requirements, qualities, and properties of the part to be manufactured. Below we discuss a few of them that have excellent qualities in plastic prototype machining.

Nylon, which is called polyamide too, is a general-purpose machining material. It comes in many different grades. Its characteristics include good elasticity, its washable and dyeable, and can also to bear against high levels of heat. Nylon finds its applications in the manufacturing of parts like automotive parts, parachute canopies, etc.

ABS stands for Acrylonitrile Butadiene Styrene. It’s a favorable choice when it comes to good toughness and strength because of its excellent chemical and thermal stability. ABS is a terpolymer being manufactured by applying a polymerization process to styrene and acrylonitrile in the presence of polybutadiene. Its general properties include high rigidity, good insulating properties, high dimensional stability, and high surface brightness. ABS finds its applications in the making of parts like refrigeration components, control panels, keyboard keys, etc.

POM stands for Polyoxymethylene (that is known as Delrin, polyacetal, or acetal too). It is an engineering thermoplastic and its properties include low moisture sensitivity, good electrical conductivity, high strength, and toughness, etc. POM finds its applications in the manufacturing of parts such as automotive clips, seatbelt adjuster, etc.

PC stands for polycarbonate. This material also finds very helpful in making excellent plastic prototyping. Generally, polycarbonates are strong, stiff, hard, and tough engineering thermoplastics. It is used in plastic CNC machining for making different parts like Blu Ray discs, swimming goggles, etc.

PP stands for polypropylene (also known as polypropene) is a hydrocarbon polymer. PP is one of the most commonly produced plastics in the world. Polypropylene is such a thermoplastic that offers an excellent blend of physical, chemical, mechanical, thermal, and electrical properties.

Its properties include excellent chemical and electrical resistance, low cost, lightweight, good fatigue resistance, recyclable, and excellent weldability. As PP offers outstanding adaptability therefore it is usually referred as ‘steel of the plastic industry’. PP finds its applications in plastic parts for various industries like the automotive industry, special devices like living hinges, and textiles etc.

PEEK stands for polyether ether ketone, is a semi-crystalline engineering thermoplastic and is preferred in high-performance part productions. During machining, PEEK has a high tendency to break due to high temperature and high internal stress. Therefore, a seasoned worker needs to deal with it.

Its properties include excellent chemical resistance, low moisture absorption, excellent strength and wear resistance. During machining, it shows high accuracy, tight tolerances and high repeatability.