15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

394 |

Published by VMT at Nov 19 2021

394 |

Published by VMT at Nov 19 2021

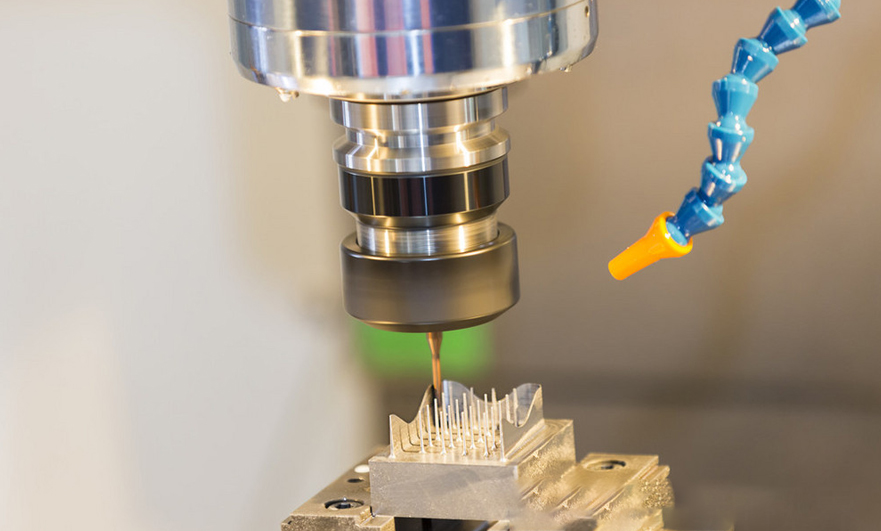

Metal CNC machining and manufacturing refers to a machining process in which finished products are produced from raw materials. There are a variety of CNC machining services, and different machining CNC machining parts can be applied to different machining methods.

Manufacturing refers to any process that cuts, shapes, or otherwise forms a final product. The disadvantages of plastic overload are metal manufacturing and vice versa. The type of metal CNC machining manufacturing method used to produce a particular project depends on a wide range of factors, including product use, appearance, and available budget. In deciding whether plastic or metal CNC machining is suitable for a particular job, it is important to first understand the potential advantages and disadvantages of each option.

Advantages of plastic CNC machining and manufacturing

1. Plastic molding is easy:

Compared with other materials, plastic has a lower melting point and higher ductility, and can be formed into basic and complex geometric shapes relatively easily. , The melting point of plastic is very low, which helps the formation of plastic. This may be extremely beneficial to companies that CNC machining products with complex shapes.

2. CNC machining:

Plastic manufacturing is unique because it allows the possibility if the material is set in the mold before adding the desired color. Adding color to the material in advance means that the material appears the way you want, which directly eliminates the need to trim the material. Unlike most metals, plastics can be colored before production, eliminating the need for certain post-processing processes, such as painting.

3. Chemical resistance:

Compared with metals, plastics are generally less susceptible to damage from chemicals or chemical reactions (such as oxidation or rust). Most metals undergo reactions such as corrosion and oxidation, which ultimately reduce the durability of the product.

4. Light weight of plastic:

The weight of plastic is generally lighter than that of metal of comparable size.

5. Real-time production time:

Plastic CNC processing and manufacturing often involve fast cycle times and fast turnover rates.

Advantages of metal CNC machining and manufacturing

Like plastic manufacturing, metal CNC machining and manufacturing largely depends on the type and grade of metal used for production. Some of the more common metals include steel, magnesium, iron, aluminum, copper, and nickel, each of which has different grades. Compared with plastic processing, metal usually has the following advantages:

1. Durability: Metal grades tend to be stronger, harder, and more durable than plastic grades.

2. Heat resistance: metals usually have a higher melting point and are unlikely to degrade at high temperatures.

3. Cost-effectiveness: Metal is usually a cost-effective choice, especially in large-volume or long-term production runs.

4. Versatility: Metal can be manufactured through a wider range of processes, including casting, deep drawing, welding, forging, welding and chipping.

In conclusion

The metal numerical control processing manufacturing process is of great significance in the machining and manufacturing industry. It can determine the yield rate of the entire CNC machined parts production. VMT provides prototype manufacturing services for metal CNC machining.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!