15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

106 |

Published by VMT at Apr 03 2024

106 |

Published by VMT at Apr 03 2024

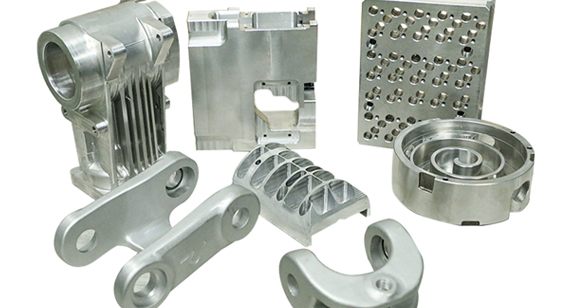

As modern manufacturing industries continue to evolve, the application of precision CNC machining parts in sectors such as aerospace, automotive manufacturing, and medical devices is becoming increasingly widespread. Five-axis CNC machining technology, as a crucial method for high-precision machining, can meet the demands of complex parts, thereby enhancing machining efficiency and accuracy. This article will delve into which precision parts necessitate five-axis CNC machining, analyzing the underlying technical principles and application values.

1. Overview of Five-Axis CNC Machining Technology

Five-axis CNC machining technology refers to machine tools with five coordinate axes, enabling multi-directional and multi-angle machining within a spatial framework. Compared to traditional three-axis machining, five-axis machining can achieve high-precision machining of complex surfaces, avoiding errors caused by multiple clamping and positioning, thus improving machining efficiency and part quality.

2. Types of Precision Parts Requiring Five-Axis CNC Machining

Complex Surface Parts:

Complex surface parts are one of the primary applications of five-axis CNC machining. These parts feature intricate spatial surface structures, such as aerospace engine blades and turbines. Traditional three-axis machining struggles to achieve high-precision machining of these surfaces, while five-axis machining can effortlessly handle them, achieving continuous and smooth machining of surfaces by adjusting tool angles and positions.

Irregular-Shaped Parts:

Irregular-shaped parts refer to parts with irregular shapes that are difficult to machine using traditional methods. These parts often have special shapes and functional requirements, such as surgical instruments in medical devices and complex connectors in automotive components. Five-axis CNC machining can flexibly adjust tool paths and cutting angles to efficiently and accurately machine irregular-shaped parts.

High-Precision Parts:

High-precision parts have extremely high requirements for machining accuracy and surface quality, such as optical lenses and precision molds. Five-axis CNC machining can achieve high-precision machining with minimal cutting allowances, ensuring that part dimensions and surface roughness meet design requirements. Moreover, five-axis machining can reduce vibrations and deformations during machining, further enhancing part precision and stability.

Large-Scale Parts:

Large-scale parts like aircraft wings and ship propellers, due to their large size and complex structures, pose challenges for traditional machining methods. Five-axis CNC machining can accomplish the overall machining of large parts, reducing errors and costs associated with segmented assembly, thereby improving the overall performance and reliability of parts.

3. Technological Advantages of Five-Axis CNC Machining

Enhanced Machining Efficiency:

Five-axis CNC machining enables one-time clamping and continuous machining of complex parts, reducing the time required for multiple clamping and positioning and improving machining efficiency. Additionally, five-axis machining can automatically adjust tool paths and cutting parameters based on part shapes and machining requirements, achieving efficient and stable machining processes.

Improved Machining Accuracy:

Five-axis CNC machining allows machining from multiple directions and angles, avoiding errors caused by tool interference and cutting force variations in traditional machining. Through precise CNC programming and tool path planning, five-axis machining can achieve machining accuracies ranging from micrometers to nanometers, meeting the high-precision machining requirements of parts.

Expanded Machining Range:

Five-axis CNC machining can reach areas and angles inaccessible by traditional machining methods, such as deep cavities and internal bores. This versatility makes five-axis machining highly applicable in industries like aerospace, medical devices, and more.

4. Application Prospects of Five-Axis CNC Machining

With the transformation and upgrading of manufacturing industries and the development of intelligent manufacturing, five-axis CNC machining technology will have broader development prospects. In the future, five-axis machining will focus on integrating with advanced manufacturing technologies such as additive manufacturing and intelligent manufacturing, forming a more efficient, precise, and intelligent machining system. Moreover, as new materials and processes emerge, five-axis machining will continue to expand its application areas, injecting new vitality into the manufacturing industry.

5. Conclusion

In summary, precision parts requiring five-axis CNC machining for high-precision and high-efficiency machining include complex surface parts, irregular-shaped parts, high-precision parts, and large-scale parts. Five-axis CNC machining technology plays an increasingly important role in the manufacturing industry, thanks to its unique advantages. With continuous technological advancement and the expansion of application areas, five-axis CNC machining will provide strong support for the transformation, upgrading, and high-quality development of the manufacturing industry.

As experts in the field of CNC machining parts manufacturing, we should closely monitor the development trends of five-axis CNC machining technology, continuously improve our technical skills and application capabilities, and actively promote the application of five-axis CNC machining technology to contribute to the progress and development of the manufacturing industry.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!