15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

110 |

Published by VMT at Mar 26 2024

110 |

Published by VMT at Mar 26 2024

Introduction:

In the realm of CNC machining part manufacturing, as demands for high precision and complexity escalate, the role of 5-axis CNC machining technology becomes increasingly pivotal. This article will delve into which precision components should opt for 5-axis CNC machining, analyzing the underlying reasons and advantages.

I. Overview of 5-Axis CNC Machining Technology:

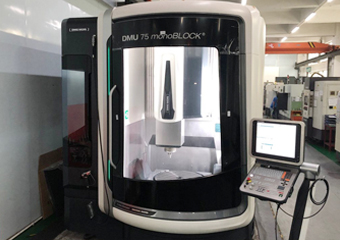

5-axis CNC machining technology utilizes five axes (X, Y, Z, A, C or B, C) to precisely control the motion of tools and workpieces, facilitating the machining of complex surfaces and high-precision components. This technology significantly enhances machining accuracy and efficiency, reduces the number of workpiece setups, and lowers production costs.

II. Types of Precision Components Suitable for 5-Axis CNC Machining:

Components with Complex Surfaces:

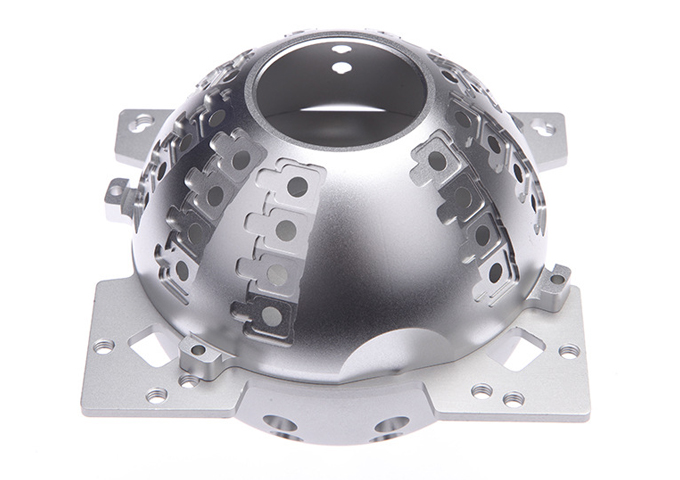

Components with intricate surface structures like aerospace engine blades, turbine components, and automotive engine cylinder heads benefit from 5-axis CNC machining. The synchronized movement of five axes enables high-precision machining of complex surfaces, meeting stringent requirements for shape and precision.

Components with High Precision Requirements:

Precision components such as intricate molds, medical devices, and optical instruments find suitability with 5-axis CNC machining. Through precise CNC programming and advanced machine control systems, micro-level or even nano-level machining accuracy can be achieved to fulfill the demands of high-precision component manufacturing.

Materials Difficult to Machine:

Some special materials like titanium alloys and ceramics pose challenges due to their high hardness, toughness, or thermal expansion coefficients, making conventional machining methods inadequate. 5-axis CNC machining technology, through optimized tool paths and cutting parameters, can achieve high-precision machining of these difficult-to-machine materials.

III. Advantages of 5-Axis CNC Machining in Precision Component Manufacturing:

Enhanced Machining Accuracy and Efficiency:

5-axis CNC machining technology, with precise CNC programming and advanced machine control systems, achieves high-precision component machining.

The synchronized movement of five axes enhances machining efficiency by significantly reducing the number of workpiece setups and machining time.

Cost Reduction:

5-axis CNC machining reduces manual intervention and errors during machining, improving machining quality.

Reduced setup times and machining durations lower production costs. Additionally, for batch production, programming and automated machine operation further enhance efficiency and reduce production costs.

Enhanced Component Competitiveness:

Precision components manufactured using 5-axis CNC machining, with characteristics of high precision, quality, and efficiency, gain competitiveness in the market.

This technology meets customer demands for high-precision, high-quality components, enhancing product value and market share.

IV. Considerations for CNC Machining Factories When Choosing 5-Axis CNC Machining:

CNC machining factories, when considering the adoption of 5-axis CNC machining technology, should evaluate various factors:

Assess their technical capabilities and equipment conditions to ensure proficient application of 5-axis CNC machining.

Evaluate component machining requirements and market prospects to determine if adopting 5-axis CNC machining technology yields economic benefits and market competitiveness.

Stay abreast of the development trends and future applications of 5-axis CNC machining technology to adjust and optimize machining capabilities timely.

Conclusion:

In conclusion, choosing 5-axis CNC machining technology is a prudent decision for precision components with complex surfaces, high precision requirements, or difficult-to-machine materials. This technology leverages its advantages in high precision, efficiency, and flexibility to meet the demands of precision component manufacturing. CNC machining factories should consider their technical capabilities, component machining requirements, and market prospects when deciding to adopt 5-axis CNC machining, ensuring effective application of the technology and maximization of economic benefits.

As technology advances and market demands evolve, 5-axis CNC machining technology will play an increasingly vital role in the future. As experts in CNC machining part manufacturing, we should actively monitor the development trends of this technology, continually learn and master new technologies and processes, and contribute to the continuous advancement and innovation of the industry.

This concludes the in-depth exploration of which precision components should choose 5-axis CNC machining. It is hoped that this article provides readers with valuable knowledge and insights, fostering progress and development in the CNC machining part manufacturing field.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!