15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

142 |

Published by VMT at Oct 05 2022

142 |

Published by VMT at Oct 05 2022

Precision CNC machining has become a pillar of the manufacturing industry. More and more CNC machining manufacturers are adopting this form of machining in their operations. Although many CNC machining masters are accustomed to this form of CNC machining, not all of them know the logic behind it. The main advantages of using precision CNC machining over other forms of machining are as follows:

1. More automated and more precise

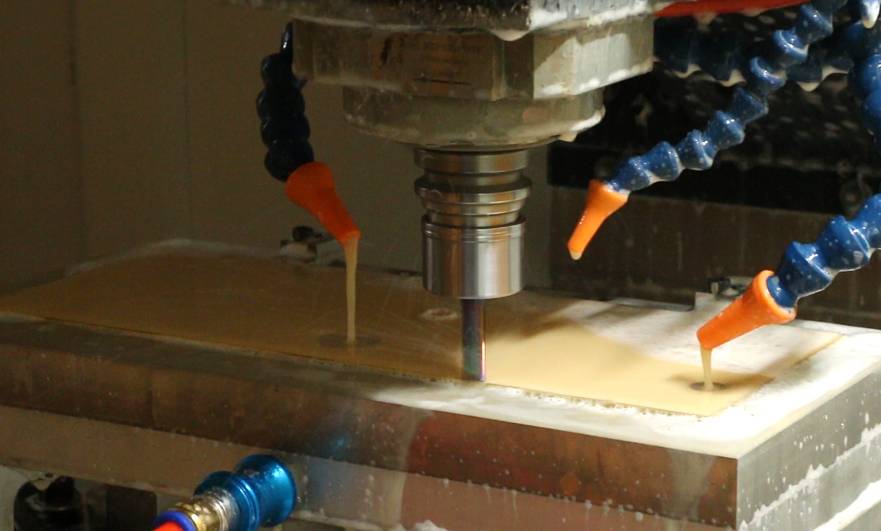

CNC machining stands for Computer Numerical Control - This form of machining relies heavily on computer control. This means a higher level of automation, the best solution for high-precision work. The main differences and benefits of using CNC machining compared to traditional production methods are: more machining processes are automated, reducing the occurrence of human errors and satisfying people's need for higher precision. The main function of precision CNC machining is the ability to create other things from a piece of plastic or metal. Although traditional CNC machining can achieve these goals, the automation used in CNC machining enables higher processing efficiency, faster speed, higher production speed, and less error space, making CNC machining reduce the cost of many enterprises.

2. CNC machining different types of precision CNC machining parts

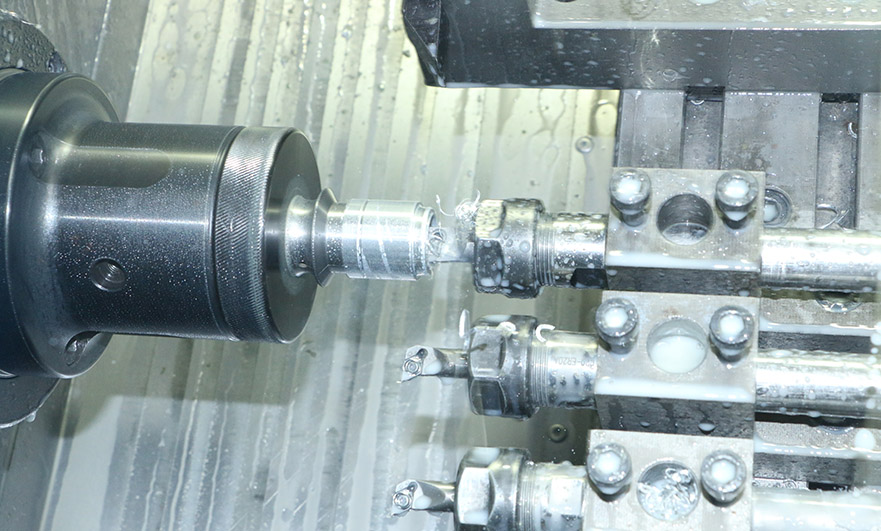

Modern CNC machining is suitable for various cutting methods. CNC turning machining makes it possible to manufacture complex exterior and interior geometries. For example, CNC turning and CNC milling. During CNC turning, the raw material is machined, making it possible to manufacture "complex external and internal geometries, including the generation of various threads." CNC milling is better for making holes, slots, and repetitive movements to create complex three-dimensional shapes. Milling is versatile, easy to set up repetitive operations, and is often used to make plastic injection molding molds.

3. Meet all your CNC parts customization needs

There is no tool in this industry that can handle all manufacturing needs, but CNC machining is the closest. It can create curves and angles where it was once flat and smooth. It can add grooves and threads to create locking mechanisms. It can stamp and engrave, cut and drill, and add texture and contour. Since it's run by a computer program, you can customize it to make almost any mechanical part you can imagine. The computer programming process uses computer-aided design, or CAD for short, to create a model of the final product. This is a rough draft as the process progresses. It can also identify any issues in the design. The prototype is then photographed, which creates a copy and feeds it into the machine.

4. Safety, reduced labor

Although the operator plays an important role in CNC machining, the operator does not operate on the machine by hand, but on the computer. This creates a safer work environment for all and reduces workplace accidents. This is especially important because in the past repetitive manual labor was performed by workers. CNC machining ensures that the resulting product is consistent and meets quality control guidelines. Human error and lack of sleep are a common hidden danger, which can lead to accidents, and there is no need to worry about CNC machining.

5. Convenient and fast

Since the CNC machining process is efficient and computer-led, it is easy to mass produce. You just need to have multiple machines running on the same program. For many businesses, scaling up while maintaining good profit margins is a challenge. CNC machining has the function of storage, so you don't have to worry about reloading the program every time, and you don't have to re-enter the command every time you produce a product. CNC machining its many benefits make it the best choice for precision CNC machining manufacturers.

The above is just a summary of the VMT CNC machining factory. If you want to know more about CNC machining, you can contact us: inquiry@vimetal.com.cn to discuss with us.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!