15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

114 |

Published by VMT at Mar 25 2024

114 |

Published by VMT at Mar 25 2024

The Relationship Between CNC Machining Lead Time and Production Efficiency

In the realm of CNC machining part manufacturing, there exists a close relationship between CNC machining lead time and production efficiency. Lead time represents the customer's expectations for part delivery, directly reflecting their demands for machining speed and efficiency. This article will delve into the intricacies of the relationship between CNC machining lead time and production efficiency, analyzing strategies to optimize this connection for improved overall operational performance.

I. Impact of CNC Machining Lead Time on Production Efficiency

Shorter Lead Time and Increased Efficiency:

Short lead times necessitate heightened production efficiency to meet customer demands promptly.

Factories must optimize production processes, enhance equipment utilization, and minimize non-production time to fulfill more tasks within limited time frames.

These measures, while maintaining quality, elevate production efficiency to meet customer lead time requirements.

Risks of Excessively Short Lead Time:

Extremely tight lead times may lead to reduced production efficiency.

Intense time pressures can result in excessive equipment usage and employee fatigue, potentially causing a decline in machining quality and increased equipment failure rates.

Setting realistic lead times is essential, considering the factory's actual production capacity and resources to avoid sacrificing long-term efficiency for short-term gains.

II. Impact of Production Efficiency on CNC Machining Lead Time

Shortened Lead Time through Improved Efficiency:

Enhanced production efficiency allows factories to complete machining tasks in shorter durations.

By optimizing production processes, improving equipment precision and stability, and investing in employee training, factories significantly boost production efficiency.

Quick responsiveness to urgent orders or short lead time requirements earns trust and positive feedback from customers.

Cost Reduction and Market Competitiveness:

Increased production efficiency contributes to reduced production costs.

Efficient processes lead to effective resource utilization, minimizing waste and elevating factory profitability.

Cost reduction enhances the factory's competitiveness in pricing, attracting more customers and expanding market share.

Balancing Efficiency for Sustainability:

Overemphasis on efficiency might lead to issues such as excessive equipment wear and employee fatigue.

Balancing high efficiency with sustainability considerations ensures stable lead times.

Factories should focus on long-term efficiency, considering the well-being of both the production process and the workforce.

III. Strategies to Optimize the Relationship

Strategic Production Planning:

Develop realistic production plans aligned with customer demands and the factory's actual production capacity.

Ensure balanced task distribution and efficient resource utilization to prevent bottlenecks and waste in the production process.

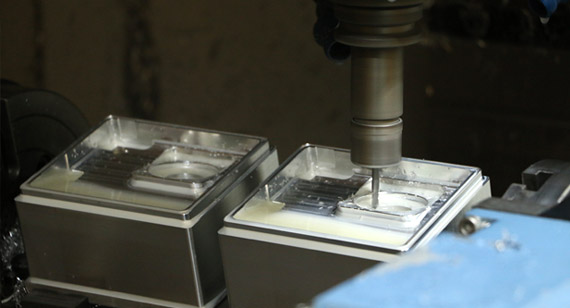

Investment in Advanced Equipment and Technology:

Introduce advanced CNC machining equipment and technologies to improve machining precision and efficiency.

Prioritize equipment maintenance to ensure stability and extend lifespan.

Employee Training and Motivation:

Provide regular training to enhance employee skills and efficiency awareness.

Establish incentive mechanisms to encourage employee participation in production improvements and innovations.

Optimization of Production Processes and Management:

Implement advanced management methods such as lean production and Six Sigma to optimize production processes and management systems.

Reduce non-production time, lower production costs, and enhance product quality and on-time delivery rates.

Building Strong Customer Relations:

Maintain close communication with customers to understand their needs and feedback.

Enhance customer trust and loyalty by delivering quality services and solutions, stabilizing lead times, and improving production efficiency.

Conclusion:

In conclusion, the relationship between CNC machining lead time and production efficiency is intricate. By employing strategies like strategic production planning, investment in advanced equipment, employee training, optimization of production processes, and building strong customer relations, CNC machining factories can optimize this relationship. This optimization leads to elevated overall operational performance and a competitive edge in the market.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!