15 years one-stop China custom CNC machining parts factory

709 |

Published by VMT at Aug 22 2023

709 |

Published by VMT at Aug 22 2023

What is Sandblasting? Pros and Cons of Sandblasting

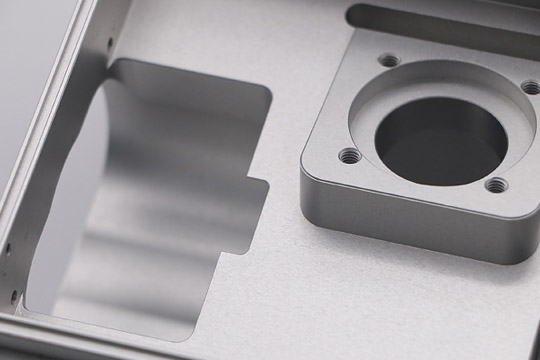

Sandblasting, also known as abrasive blasting, is a surface preparation technique that involves propelling abrasive particles at high speeds to clean, smooth, or reshape a surface. This process is commonly used in various industries for cleaning, finishing, and restoring surfaces. Here, we explore the advantages and disadvantages of sandblasting.

Sandblasting is a versatile method used to clean, prepare, or modify surfaces using abrasive particles propelled through compressed air or other methods. It is effective in removing rust, paint, scale, and contaminants from various materials.

The Sandblasting Process

Abrasive Selection: Different abrasive materials, such as sand, aluminum oxide, or glass beads, can be chosen based on the specific application.

Surface Preparation: The surface is cleaned and prepared by directing abrasive particles at high velocities, effectively removing unwanted materials.

Impact and Abrasion: The abrasive particles impact the surface, dislodging debris and creating a desired texture or finish.

Applications: Sandblasting is used in industries like automotive, construction, and manufacturing for cleaning, rust removal, paint stripping, and surface preparation.

Advantages of Sandblasting

Efficient Cleaning: Sandblasting quickly removes tough contaminants, rust, and old coatings from surfaces.

Uniform Surface Finish: The process provides a consistent surface texture, ideal for applying coatings and paints.

Selective Preparation: Different abrasives can be chosen to achieve specific results on various materials.

Multiple Applications: Sandblasting is versatile, suitable for a wide range of materials and surfaces.

Environmentally Friendly: Proper containment and recycling of abrasives can make the process environmentally responsible.

Disadvantages of Sandblasting

Health Risks: Inhaling airborne abrasive particles can lead to respiratory issues; thus, proper safety measures are crucial.

Surface Damage: Aggressive abrasives or improper technique can damage sensitive surfaces or substrates.

Environmental Impact: If not properly contained, airborne abrasives can contribute to pollution.

Limited Precision: Sandblasting might not be suitable for intricate or delicate work.

Safety Considerations

Protective Gear: Operators must wear appropriate safety equipment, including respirators, goggles, and protective clothing.

Proper Ventilation: Adequate ventilation systems help prevent the buildup of airborne particles in the workspace.

Training: Proper training in operating equipment and safety procedures is essential to minimize risks.

Conclusion

Sandblasting offers efficient surface preparation and cleaning benefits across various industries. While it provides advantages like uniformity and versatility, safety precautions are paramount due to potential health risks and environmental concerns. Understanding the pros and cons of sandblasting ensures its effective and safe application in a wide range of projects.

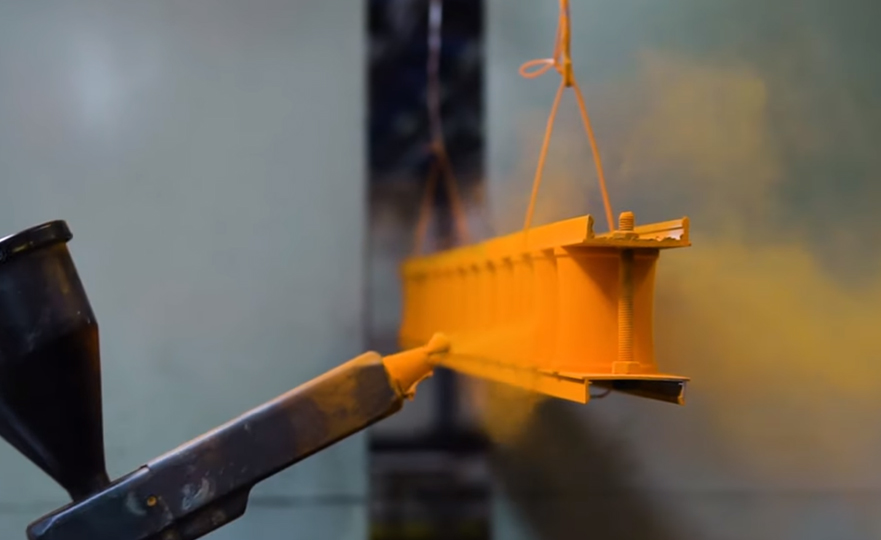

What is Powder Coating? Pros and Cons of Powder Coating

Powder coating is a modern and widely used surface finishing process that involves applying a dry powder to a substrate and then curing it to create a durable and attractive finish. This article explores the advantages and disadvantages of powder coating.

Powder coating is a popular method for applying a protective and decorative finish to various surfaces, including metal, wood, and plastic. It offers benefits such as durability, versatility, and an environmentally friendly application process.

The Powder Coating Process

Preparation: The substrate is cleaned and pre-treated to ensure proper adhesion of the powder.

Application: Powder particles are electrostatically charged and sprayed onto the substrate, creating a uniform and thick coating.

Curing: The coated object is placed in an oven where the powder particles melt and fuse to create a smooth and durable finish.

Cooling and Inspection: After curing, the object is cooled and inspected to ensure a flawless finish.

Advantages of Powder Coating

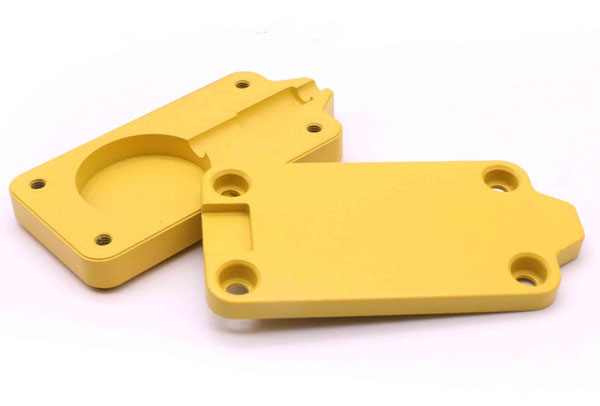

Durability: Powder coatings are resistant to chipping, scratching, and fading, ensuring a longer-lasting finish.

Variety of Finishes: Powder coatings come in a wide range of colors, textures, and finishes, providing versatility in design.

Environmental Benefits: Powder coating is solvent-free and generates minimal waste, making it an environmentally friendly option.

Efficiency: The powder adheres evenly, reducing the need for multiple coats and minimizing wastage.

Uniform Coverage: Complex shapes and surfaces can be evenly coated due to the electrostatic application process.

Disadvantages of Powder Coating

Limited Thickness: Powder coatings might not achieve the same thickness as liquid coatings, impacting certain heavy-duty applications.

Surface Preparation: Proper surface cleaning and pre-treatment are essential for achieving optimal adhesion.

Curing Time and Equipment: Curing in an oven requires time and specialized equipment, affecting production timelines.

Re-coating Difficulty: Re-coating or color changes can be challenging due to the need to strip the existing coating.

Environmental Considerations

Volatile Organic Compounds (VOCs): Powder coating generates minimal to no VOC emissions, contributing to a healthier environment.

Conclusion

Powder coating is a versatile and durable finishing method with a range of advantages, including durability, environmental benefits, and variety in finishes. While it might have some limitations, understanding its pros and cons allows for informed decisions in choosing the right coating method for different applications.

Differences Between Sandblasting and Powder Coating: Comprehensive Comparison

Sandblasting and powder coating are two distinct surface finishing techniques that offer different benefits and applications. This detailed comparison explores the differences between sandblasting and powder coating across various aspects to help you understand their unique characteristics.

Sandblasting and powder coating are widely used methods for enhancing and protecting surfaces. Understanding their differences in terms of process, advantages, and drawbacks can guide you in selecting the appropriate technique for your specific requirements.

Sandblasting Process vs. Powder Coating Process

Sandblasting: Involves propelling abrasive particles at high speeds to clean, smooth, or reshape a surface, preparing it for coating.

Powder Coating: Involves applying a dry powder electrostatically to a substrate and then curing it in an oven to create a durable finish.

Surface Effects: Sandblasting vs. Powder Coating

Sandblasting: Creates a textured, matte, or satin-like finish by removing surface impurities and preparing the substrate for coatings.

Powder Coating: Offers a smooth and consistent finish, available in a wide range of colors, textures, and gloss levels.

Cost Comparison

Determining which method is more cost-effective depends on factors such as project size, complexity, material, and desired finish.

Sandblasting: Generally, sandblasting tends to be more affordable due to its straightforward process and lower material costs.

Powder Coating: While typically pricier than sandblasting, powder coating's durability and aesthetic benefits can offset the initial investment.

Factors Influencing Costs

Material and Size: Larger or intricate parts might require more time and effort, impacting costs.

Preparation Requirements: Extensive surface preparation in sandblasting could increase costs, while powder coating's even application might lead to a higher price.

Finish Complexity: Intricate designs, unique textures, or special effects can influence costs for both methods.

Advantages of Sandblasting

Effective Cleaning: Sandblasting efficiently removes tough contaminants and prepares surfaces for coating.

Surface Texture Preparation: Sandblasting creates a textured surface ideal for coatings and paints to adhere to.

Selective Cleaning: Different abrasives can be used to achieve specific results on various materials.

Advantages of Powder Coating

Durability: Powder coatings offer resistance to chipping, scratching, and fading, ensuring a long-lasting finish.

Variety of Finishes: Powder coatings come in a wide range of colors, textures, and finishes, providing design versatility.

Environmental Friendliness: Powder coating is solvent-free, generates minimal waste, and has low VOC emissions.

Disadvantages of Sandblasting

Health Risks: Inhaling airborne abrasive particles during sandblasting can pose respiratory hazards.

Surface Damage: Aggressive abrasives or improper technique can damage sensitive surfaces.

Environmental Concerns: Uncontained abrasive particles can contribute to pollution if not managed properly.

Disadvantages of Powder Coating

Limited Thickness: Powder coatings might not achieve the same thickness as liquid coatings.

Curing Time and Equipment: Curing in an oven requires time and specialized equipment.

Re-coating Challenges: Changing colors or re-coating can be challenging due to the need for stripping existing coatings.

Sandblasting

Process: Sandblasting involves using abrasive particles propelled at high speeds to clean, prepare, and texture surfaces.

Purpose: It is primarily used for surface preparation by removing rust, paint, and contaminants.

Applications: Sandblasting is crucial before applying coatings, paint, or other treatments to ensure proper adhesion.

Powder Coating

Process: Powder coating applies a dry powder electrostatically to a surface and then cures it to create a durable finish.

Purpose: It combines protection and aesthetics, providing a range of colors, textures, and finishes.

Applications: Powder coating is commonly used in industries like automotive, architecture, and appliances for enhanced appearance and durability.

Comparative Analysis

Method: Sandblasting focuses on preparing surfaces by cleaning, roughening, and texturing them.

Outcome: Powder coating enhances appearance, protection, and durability of surfaces.

Application: Sandblasting is a prerequisite for coatings, while powder coating is applied as a finish.

Application Considerations

Sandblasting: Primarily used for surface preparation and cleaning before coatings.

Powder Coating: Suitable for both protection and aesthetics, providing a range of finishes.

Environmental Impact

Sandblasting: Can generate airborne pollutants if not properly contained.

Powder Coating: Offers environmental benefits with low VOC emissions and minimal waste generation.

Conclusion

Sandblasting and powder coating have distinct advantages and drawbacks that cater to specific requirements. The distinctions between sandblasting and powder coating lie in their processes, objectives, and applications. Sandblasting is essential for surface preparation, while powder coating enhances both aesthetics and protection. Understanding their differences empowers you to make informed decisions for your projects, ensuring optimal results in terms of surface preparation, finish quality, and environmental impact.

Sandblasting vs. Powder Coating: Which is the Best Fit for You?

Deciding between sandblasting and powder coating depends on your specific project needs and desired outcomes. This article delves into the factors to consider when choosing between these two surface finishing methods.

Sandblasting and powder coating are versatile techniques used to enhance surfaces for both functional and aesthetic purposes. Evaluating your project's requirements will help you determine the most suitable method for achieving your desired results.

Understanding Sandblasting

Purpose: Sandblasting is primarily used for surface preparation by removing contaminants, rust, and old coatings.

Benefits: Provides a clean, textured surface ideal for coatings and paints. Offers versatility in abrasive selection for specific materials.

Exploring Powder Coating

Purpose: Powder coating combines protection and aesthetics, providing a durable and attractive finish.

Advantages: Offers a range of colors, textures, and finishes. Environmentally friendly with low VOC emissions and minimal waste.

Comparing Sandblasting and Powder Coating

Surface Preparation: Sandblasting focuses on cleaning and roughening surfaces, while powder coating enhances appearance and durability.

Applications: Sandblasting is crucial for preparing surfaces for coatings, while powder coating is suitable for protection and aesthetics.

Finish Quality: Powder coating provides a uniform and durable finish, while sandblasting contributes to proper adhesion of coatings.

Choosing the Right Method

Consider the following factors:

Surface Condition: Choose sandblasting for surface preparation, especially for rough or contaminated surfaces.

Finish Requirements: Opt for powder coating when both protection and aesthetics are important, ensuring a durable and visually appealing result.

Project Scale: Consider the scope of your project; large-scale projects might benefit from the efficiency of powder coating.

Conclusion

The decision between sandblasting and powder coating hinges on your project's goals. Sandblasting is essential for preparing surfaces, while powder coating offers a combination of protection and aesthetics. By understanding the unique benefits of each method and aligning them with your project's needs, you can confidently choose the method that best suits your specific requirements, ensuring the success and longevity of your endeavors.

Applications of Sandblasting and Powder Coatin

Sandblasting and powder coating are two distinct surface treatment methods with diverse applications in various industries. This article explores the specific uses of each technique and where they excel.

Sandblasting and powder coating play essential roles in preparing and finishing surfaces to meet specific functional and aesthetic requirements. Understanding their applications helps you make informed decisions for your projects.

Sandblasting Applications

Surface Preparation: Sandblasting is crucial for cleaning and preparing surfaces before applying coatings, paints, or other treatments.

Rust Removal: Sandblasting efficiently removes rust, corrosion, and old paint from metal surfaces, restoring their integrity.

Surface Texturing: Sandblasting can create various textures on surfaces, adding aesthetics to architectural and artistic applications.

Deburring: Sandblasting removes burrs and sharp edges from metal parts, improving safety and functionality.

Powder Coating Applications

Metal Fabrication: Powder coating enhances the appearance and durability of metal products, from furniture to industrial equipment.

Automotive Industry: Powder coating is widely used for vehicle parts, such as wheels, frames, and bumpers, due to its durability and aesthetic options.

Architectural Elements: Powder coating is applied to aluminum and steel for doors, windows, and outdoor fixtures, offering weather resistance and design flexibility.

Appliance Manufacturing: Household appliances benefit from powder coating's protective finish, enhancing their longevity and appearance.

Comparative Analysis

Sandblasting: Primarily used for surface preparation, rust removal, and texturing before applying coatings.

Powder Coating: Used to enhance the appearance, durability, and corrosion resistance of various objects, particularly in industries such as automotive and architecture.

Conclusion

Sandblasting and powder coating serve vital roles in improving surface quality and longevity. Sandblasting prepares surfaces for subsequent treatments, while powder coating enhances appearance and protection. By recognizing their unique strengths and applications, you can choose the appropriate method for your specific projects, achieving the desired results in terms of both functionality and aesthetics.

Find a reliable partner

Do you know how to choose the right finish for your project? Or, if you need expert help enhancing part finish and performance, VMT can help.

We provide custom CNC metal machining finishing services for steel, aluminum, titanium, copper and more. Whether it is prototyping or small batch CNC machining production of parts, our team of professional engineers can select the appropriate surface treatment for you and meet your needs with high standards. Then, just upload your CAD file to our email: inquiry@vimetal.com.cn to get a project quotation.

Frequently Asked Questions About Sandblasting and Powder Coating

Here are some common questions and answers about the processes of sandblasting and powder coating:

Sandblasting:

What is sandblasting used for?

Sandblasting is used to clean, prepare, and texture surfaces by propelling abrasive particles at high speeds.

Is sandblasting safe for all materials?

While effective, sandblasting might damage delicate materials. Alternate abrasives are used for sensitive surfaces.

What safety precautions are necessary during sandblasting?

Protective gear, proper ventilation, and containment of abrasive particles are crucial to prevent health risks and pollution.

Can sandblasting remove rust completely?

Sandblasting efficiently removes rust, but thorough pre-treatment is essential to prevent its recurrence.

Can sandblasting create intricate designs?

Sandblasting can create detailed textures, but intricate designs might require additional methods.

Powder Coating:

What materials can be powder coated?

Metal, wood, plastic, and even certain ceramics can be powder coated to achieve a durable finish.

How is powder coating environmentally friendly?

Powder coating produces minimal waste, emits low levels of VOCs, and is solvent-free.

Is powder coating resistant to fading and chipping?

Yes, powder coatings are highly resistant to fading, chipping, and abrasion.

Can I choose custom colors and finishes for powder coating?

Powder coatings come in a wide range of colors, textures, and finishes, allowing for customization.

Can powder coating be applied to intricate shapes?

Yes, the electrostatic process of powder coating ensures even coverage on complex shapes.

Conclusion

Understanding the frequently asked questions about sandblasting and powder coating provides valuable insights into the benefits, limitations, and safety considerations of each process. Whether you're looking to prepare surfaces or enhance their appearance, these answers help you make informed decisions for your projects.