15 years one-stop China custom CNC machining parts factory

956 |

Published by VMT at Aug 23 2023

956 |

Published by VMT at Aug 23 2023

What is Etching? Pros and Cons of Etching

Etching is a surface treatment technique that involves selectively removing material from a substrate using chemical processes. This method is used to create intricate patterns, designs, and textures on various materials. While etching offers several advantages, it also comes with certain drawbacks that need to be considered.

How Etching Works?

Etching begins by applying a mask or resist to the material's surface, protecting certain areas from the etchant – a chemical solution that dissolves the unprotected areas. The etchant interacts with the exposed areas, removing material and leaving behind the desired pattern or design.

Pros of Etching

Precision: Etching offers high precision, enabling the creation of intricate and detailed designs with accuracy.

Intricate Patterns: This technique allows for the production of intricate and complex patterns that might be challenging to achieve through other methods.

Versatility: Etching can be applied to a wide range of materials, including metals, glass, ceramics, and even semiconductors in electronics.

Customization: The selective nature of etching allows for customizable designs and patterns tailored to specific requirements.

Reproducibility: Once the etching process parameters are established, the same design can be consistently reproduced.

Cons of Etching

Material Limitations: Etching might be limited to certain materials that are compatible with the etching process and chemicals.

Depth Control: Achieving precise and uniform depth during etching can be challenging, impacting the final appearance.

Complexity: Etching intricate designs can be time-consuming and require skilled technicians, potentially increasing production costs.

Chemical Waste: The chemicals used in etching can be hazardous and require proper disposal and waste management.

Environmental Impact: The chemicals used in etching can have environmental implications if not handled and disposed of properly.

In conclusion, etching is a versatile method for achieving intricate and detailed surface modifications, making it suitable for a wide range of applications. While it offers precision and customization, it's essential to consider its limitations and potential environmental impact when choosing it as a surface treatment method.

How Many Methods are There for Etching Surface Treatment?

There are Several Methods of Etching:

Etching, a surface treatment technique involving selective material removal using chemical processes, offers various methods to achieve desired results. Each method possesses distinct characteristics suited to different applications and requirements. Here are some common etching methods:

1. Chemical Etching:

Chemical etching involves immersing the material in a chemical solution that reacts with the exposed areas to selectively dissolve the material. It's widely used for creating intricate designs on metals, glass, and other materials.

2. Photochemical Etching:

Photochemical etching combines photolithography and chemical etching. A light-sensitive mask, called a resist, is applied to the material's surface. After exposure to light, the unexposed areas are washed away, leaving behind a pattern. The exposed areas are then etched using a chemical solution.

3. Electrochemical Etching:

In electrochemical etching, electrical current is passed through the material while it's immersed in an electrolyte solution. This enhances the chemical etching process, allowing for controlled and precise removal of material.

4. Dry Etching:

Dry etching involves using plasma or reactive gases to remove material. This method is commonly used in microfabrication and semiconductor manufacturing to achieve extremely precise and controlled etching.

5. Wet Etching:

Wet etching uses liquid chemical solutions to dissolve material. It's often used in industries like electronics and jewelry making to create intricate patterns and designs.

6. Reactive Ion Etching:

Reactive ion etching (RIE) is a dry etching method that uses ions to chemically react with the material's surface. It's frequently used in microfabrication to create precise features on semiconductor wafers.

7. Laser Etching:

Laser etching involves using a high-energy laser beam to remove material from the surface. It's utilized for various applications, including engraving, marking, and creating intricate designs.

Each etching method has its advantages and limitations, making it crucial to select the most appropriate technique based on factors such as material type, desired pattern complexity, precision, and the specific application's requirements.

What is Sandblasting? Pros and Cons of Sandblasting

Sandblasting is a surface treatment technique that involves propelling abrasive particles at high speeds to clean, roughen, or reshape a surface. This method is used in various industries for tasks such as cleaning, surface preparation, and creating textured finishes. While sandblasting offers several advantages, it also comes with certain drawbacks that need to be considered.

How Sandblasting Works?

In sandblasting, abrasive particles, such as sand or other types of media, are propelled using compressed air or other methods onto the surface to be treated. The impact of these particles removes contaminants, old coatings, and irregularities, leaving behind a clean and often textured surface.

Pros of Sandblasting

Effective Cleaning: Sandblasting efficiently removes rust, corrosion, paint, and other surface contaminants, restoring materials to their original condition.

Surface Preparation: It provides an ideal surface for the application of coatings, paints, and adhesives by creating a clean, roughened texture that enhances adhesion.

Texture Creation: Sandblasting can create various textures on surfaces, offering both functional benefits and aesthetic appeal.

Versatility: Sandblasting can be used on a wide range of materials, including metals, concrete, glass, and wood.

Quick Process: Sandblasting is a relatively fast process, making it efficient for large-scale projects.

Cons of Sandblasting

Health and Safety Concerns: The process generates dust and airborne particles that can be hazardous if proper safety measures are not taken.

Environmental Impact: Dust and waste generated during sandblasting need to be properly contained and disposed of to avoid environmental contamination.

Surface Damage: Improper sandblasting techniques or abrasive selection can damage delicate materials or surfaces.

Regulations: In some areas, sandblasting is subject to regulations due to its potential impact on air quality and health.

Equipment and Setup: Sandblasting requires specialized equipment and setup, which can add to project costs.

In conclusion, sandblasting is a versatile method for achieving effective cleaning, surface preparation, and texture creation. However, it's essential to address health and safety concerns, environmental impact, and potential surface damage when considering sandblasting as a surface treatment method.

Differences Between Etching and Sandblasting: In-Depth Comparison

Etching and sandblasting are two distinct surface treatment techniques with unique characteristics and applications. This comprehensive comparison delves into the differences between these methods to help you choose the most suitable approach for your specific project.

Etching

Process: Etching involves selectively removing material using chemical reactions, creating intricate patterns or designs on a surface.

Precision: Etching offers high precision, making it ideal for detailed and complex designs.

Materials: It is commonly used on metals, glass, and certain polymers, offering precise control over depth and shape.

Sandblasting

Process: Sandblasting uses high-speed abrasive particles to clean, roughen, or reshape surfaces by impact.

Surface Texture: Sandblasting can create diverse textures, suitable for achieving specific surface finishes.

Materials: It's applicable to various materials, including metals, glass, ceramics, and more.

Comparative Analysis

Method: Etching relies on chemical reactions to selectively remove material, while sandblasting employs abrasive particles for surface modification.

Precision: Etching excels in achieving intricate precision for delicate designs, while sandblasting is adept at creating textured finishes.

Surface Texture: Sandblasting primarily focuses on altering surface texture, whereas etching primarily alters the surface appearance.

Applications: Etching is commonly used for decorative arts, electronics, and microfabrication. Sandblasting is often employed for surface preparation, cleaning, and texture creation.

Conclusion

Etching and sandblasting offer distinct methods of surface treatment, each with its unique advantages. Etching excels in achieving precision and intricate designs, while sandblasting is excellent for creating textured finishes and preparing surfaces for coatings. By recognizing these differences, you can select the most appropriate method to achieve your desired surface modifications accurately and effectively.

Differences in Surface Effects Between Etching and Sandblasting: Cost Comparison

Etching and sandblasting are distinct surface treatment methods that yield different surface effects and come with varying cost considerations. This comparison explores the surface effects created by each method and provides insights into their relative costs.

Surface Effects: Etching vs. Sandblasting

Etching: Creates intricate and detailed patterns or designs through selective material removal using chemical reactions. The surface appearance is altered, providing aesthetic enhancements.

Sandblasting: Achieves a textured, matte, or satin-like finish by removing impurities and preparing surfaces. Surface texture is altered, enhancing both appearance and adhesion.

Cost Comparison

Determining the cost-effectiveness of each method depends on factors like project size, complexity, material, and desired finish.

Etching: Can be cost-effective for intricate designs due to precision. Smaller-scale projects might incur lower costs.

Sandblasting: Generally more affordable due to simpler processes and lower material costs.

Factors Influencing Costs

Design Complexity: Etching intricate designs might be more time-consuming and labor-intensive.

Surface Area: Larger areas may require more resources, impacting costs for both methods.

Materials: Material type can influence processing time and material compatibility, affecting overall costs.

Conclusion

Etching and sandblasting yield distinct surface effects, catering to different aesthetic and functional preferences. While etching can achieve intricate designs with added cost, sandblasting offers textured finishes at a generally lower expense. By considering factors like design complexity, surface area, and material type, you can determine the most suitable method that aligns with your desired surface effects and budget constraints.

Etching vs. Sandblasting: Which is Right for You?

Choosing between etching and sandblasting depends on your specific project requirements, desired outcomes, and preferences. This comparison aims to guide you in selecting the most suitable surface treatment method based on your needs.

Etching

Advantages: Etching excels in achieving intricate designs and patterns with high precision. It's ideal for decorative arts, electronics, and microfabrication.

Consider If: You seek fine details, intricate customization, and intricate patterns on metals, glass, or polymers.

Sandblasting

Advantages: Sandblasting is effective for surface preparation, cleaning, and creating textured finishes. It enhances adhesion and offers diverse texture options.

Consider If: Your project requires cleaning, roughening, or achieving specific textures on materials such as metals, glass, or ceramics.

Choosing the Right Method

Consider these factors to make an informed decision:

Design Complexity: For intricate designs, etching is suitable, while sandblasting is better for texture creation.

Material Type: Both methods are applicable to various materials, but etching is common for metals and polymers, while sandblasting suits a wider range.

Project Goals: Determine if you prioritize detailed aesthetics (etching) or functional texture (sandblasting).

Budget: Etching might incur higher costs due to precision, while sandblasting is generally more cost-effective.

Conclusion

Etching and sandblasting offer distinct advantages based on your project's unique needs. Etching is ideal for achieving detailed designs, while sandblasting excels in surface preparation and texture creation. By assessing your project's goals, material, and budget, you can confidently choose the method that best suits your requirements, ensuring optimal results for your surface treatment needs.

Can You Combine Etching with Sandblasting? Exploring Compatibility

Combining etching and sandblasting can yield unique surface effects, but the feasibility depends on factors like material compatibility, design, and desired outcome. This article examines whether it's possible to integrate these two surface treatment methods.

Etching and sandblasting are distinct surface treatment techniques that offer different effects. The possibility of combining them depends on project goals and material characteristics.

Etching and Sandblasting: Overview

Etching: Involves selective material removal using chemical reactions, resulting in intricate designs or patterns on surfaces.

Sandblasting: Uses abrasive particles to clean, roughen, or texture surfaces, enhancing adhesion and visual appearance.

Combining Etching and Sandblasting

Etching followed by Sandblasting: Applying etching first can create a textured surface with intricate designs. Sandblasting enhances the texture, achieving a unique finish.

Sandblasting followed by Etching: Sandblasting can prepare a surface, followed by etching to create intricate patterns within the textured surface.

Considerations

Material Compatibility: Not all materials are suitable for both methods. Testing on a small area is recommended.

Design Complexity: Complex designs might be challenging to execute with both methods combined.

Project Goals: Determine if the combination aligns with your desired outcome and aesthetics.

Conclusion

Combining etching and sandblasting can offer innovative results, but it requires careful planning and consideration. Experimentation, material testing, and a clear understanding of your project's objectives are essential before attempting this combination. Ultimately, the compatibility of these methods depends on your creativity, the materials used, and the intended surface effects.

Applications of Etching and Sandblasting

Etching and sandblasting are versatile surface treatment methods with various applications across industries. This article explores the diverse uses of these techniques, highlighting their contributions to different fields.

Etching and sandblasting offer unique ways to modify surfaces, catering to a wide range of applications. Understanding their uses can help you determine the most suitable technique for your specific project needs.

Etching Applications

Electronics: Etching is crucial for creating circuit patterns on printed circuit boards (PCBs) and microelectronics.

Decorative Arts: Artists use etching to create intricate designs on glass, metal, ceramics, and other materials.

Metal Machining: Etching is employed to engrave logos, text, and designs on metal objects like jewelry, signage, and industrial parts.

Sandblasting Applications

Surface Finishing: Sandblasting prepares surfaces for coatings, paints, and adhesives by creating a rough texture that enhances adhesion.

Cleaning: It removes rust, paint, and contaminants from surfaces, restoring them to their original condition.

Texturing: Sandblasting adds texture to glass, wood, and metal surfaces, providing both aesthetic appeal and improved grip.

Combined Applications

Decorative Glass: Combining etching and sandblasting can create intricate patterns and textures on glass used in windows, doors, and art pieces.

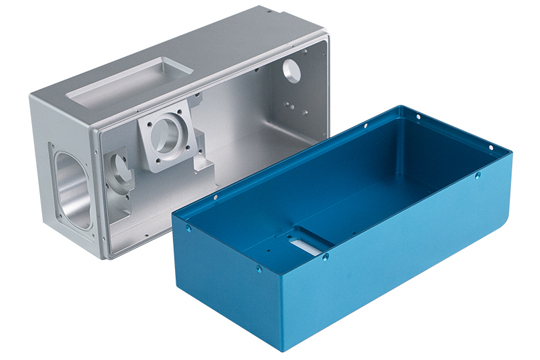

Custom Metal CNC Machining: Integrating both methods can yield unique metal surfaces with textured backgrounds and intricate designs.

Architectural Detailing: Etching and sandblasting can be employed in architectural elements like metal panels, glass facades, and signage.

Conclusion

Etching and sandblasting have extensive applications in industries ranging from electronics to art and architecture. Whether you're seeking to create detailed designs, prepare surfaces, or add texture, understanding the capabilities of these methods empowers you to choose the most appropriate technique for achieving your desired results.

Find a reliable partner

Do you know how to choose the right surface finishing for your project? VMT has 15 years of experience in surface treatment experts to choose the appropriate surface treatment for you to improve the surface finishing and performance of CNC parts.

We offer custom CNC machining services for steel, aluminum, titanium, copper and more. Whether it is prototyping or small batch production of parts, our team of professional engineers can choose the right surface treatment for you, and meet your needs with high standards. Then, just upload your CAD file to our email: inquiry@vimetal.com.cn, to get a project quotation.

Etching and Sandblasting Surface Treatments FAQ

Etching and sandblasting are popular surface treatment methods, each with its unique characteristics and applications. Here are some common questions and answers to help you understand these techniques better.

Etching and sandblasting offer diverse ways to modify surfaces, addressing various needs in industries ranging from art to manufacturing.

Etching FAQs

Q1: What is etching?

A: Etching is a technique that selectively removes material from a surface using chemical reactions, creating intricate patterns or designs.

Q2: What materials can be etched?

A: Etching is commonly used on metals like steel, aluminum, and copper, as well as glass and certain polymers.

Q3: What are the benefits of etching?

A: Etching provides precision, customization, and intricate designs for applications in electronics, decorative arts, and more.

Q4: Is etching safe for the environment?

A: Etching chemicals should be handled and disposed of properly to minimize environmental impact.

Sandblasting FAQs

Q1: What is sandblasting?

A: Sandblasting involves propelling abrasive particles at high speeds to clean, texture, or reshape surfaces.

Q2: What surfaces can be sandblasted?

A: Sandblasting is applicable to various materials such as metals, glass, concrete, and wood.

Q3: What are the benefits of sandblasting?

A: Sandblasting efficiently cleans surfaces, prepares them for coatings, and adds textures for both aesthetics and grip.

Q4: Is sandblasting safe for operators?

A: Proper safety equipment and procedures are necessary to protect operators from airborne particles.

Conclusion

Understanding the frequently asked questions about etching and sandblasting can help you make informed decisions when considering these surface treatment methods. Whether you're looking to create intricate designs or prepare surfaces for coatings, these techniques offer valuable solutions for a wide range of applications.