15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

311 |

Published by VMT at Sep 15 2022

311 |

Published by VMT at Sep 15 2022

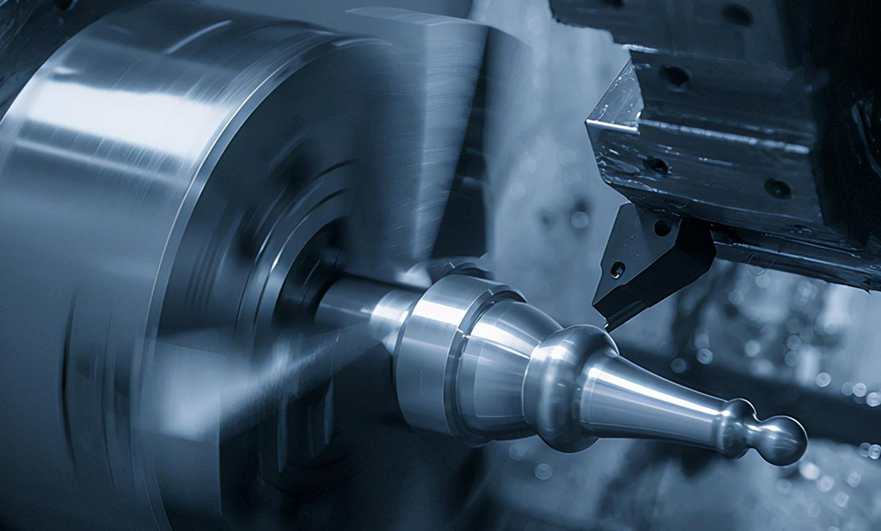

CNC machining can be divided into two types according to the machining accuracy, namely rough machining and finishing. Usually, rough machining is performed first, and then finishing is performed, which can effectively improve the machining accuracy of the workpiece. This article will mainly introduce the difference between roughing and finishing of CNC lathes, so that everyone can have a better understanding of CNC machining.

CNC machining mainly uses tools to perform CNC machining on rotating workpieces. It can CNC process various types of rotating surfaces, such as cylindrical surfaces, conical surfaces, arc surfaces and spherical surfaces, and can perform grooving, reaming and drilling. As well as various CNC machining processes such as reaming, it combines the characteristics of precision lathes and special lathes, with high CNC machining accuracy and CNC machining efficiency.

It is necessary to perform finishing after rough machining on CNC lathes, because a workpiece needs to go through various processing processes such as forging, rough machining, modulation, finishing and intermediate frequency from rough to finished product. Rough machining is generally used Before the modulation, if the rough machining is not carried out, the finishing machining will be carried out directly, and the processing volume will be very large, and after the modulation, the workpiece is relatively hard, and the cutting head will be particularly consumed from the rough turning to the finished product.

CNC (Computer Numerical Control) machining is a widely used technique in the manufacturing industry for creating precise components. Within CNC machining, there are two distinct processes: rough CNC machining and fine CNC machining. While both processes contribute to the final outcome, they differ in their objectives and techniques. In this article, we will explore and explain the differences between rough CNC machining and fine CNC machining.

Rough CNC Machining

Rough CNC machining is the initial stage in the CNC machining process. It focuses on removing excess material from the workpiece quickly and efficiently. The primary objectives of rough CNC machining are:

Material Removal: The main purpose is to eliminate the bulk of the material from the workpiece, such as excess stock or rough surfaces.

Time Efficiency: Rough machining aims to reduce the overall machining time by removing significant amounts of material in this stage.

Tool Preservation: By removing excess material in the rough machining phase, the cutting tools used in subsequent stages are subjected to less stress and wear.

To achieve these objectives, rough CNC machining employs larger cutting depths and higher feed rates. It prioritizes efficient material removal over achieving intricate geometries or fine surface finishes. Robust cutting tools capable of withstanding higher cutting forces are typically utilized in this stage.

Fine CNC Machining

Fine CNC machining follows rough CNC machining and focuses on achieving the desired precision and finish. The primary objectives of fine CNC machining are:

Dimensional Accuracy: Fine machining ensures that the workpiece meets the required dimensional specifications accurately.

Surface Finish: It aims to achieve smooth and precise surface finishes, eliminating any remaining imperfections.

Tolerance Control: Fine machining allows for tighter control over dimensional tolerances, ensuring the workpiece meets the desired precision requirements.

In fine CNC machining, smaller cutting depths and lower feed rates are employed to refine the workpiece. Precision cutting tools specifically designed for achieving intricate geometries and superior surface finishes are used. Attention to detail and meticulous precision are the hallmarks of fine CNC machining.

Roughing and finishing of CNC lathes

CNC lathe roughing is the process of removing a large amount of machining allowance from the workpiece. Roughing generally uses a low-speed large pass to quickly remove excess metal material on the workpiece, and the achieved product size is the process size of the semi-finished product rather than the process size of the finished product. The achievable precision is lower, the CNC machined surface is rough, and the production efficiency is higher, which is usually a preparation process for finishing. The machining accuracy of rough machining can generally reach IT12-IT11 level, and the surface roughness Ra value can reach 50-12.5μm.

When performing rough machining, the CNC machining speed is generally emphasized, so the cutting amount and feed amount are relatively large, and the cutting speed is relatively small, but this will cause a lot of vibration to the lathe, and also aggravate the various parts of the lathe. wear of components. If possible, we can use different lathes for roughing and finishing to better protect the mechanical equipment.

The finishing of CNC lathes is also known as precision machining. There are two main ways to realize the finishing of workpieces. One is to use high-precision CNC lathes and CNC to process workpieces with high precision; the other is to use error compensation technology to improve CNC machining. Part accuracy. The finishing CNC machining accuracy can reach IT8-IT6 level, and the surface roughness Ra value can reach 1.6-0.8μm, and even can reach Ra0.4μm under better conditions.

The main function of finishing is to improve the size and surface accuracy of CNC machined parts, not the amount of cutting. Through the process of cutting a thin layer of metal material on the surface of CNC machined parts with a high cutting speed and a small amount of cutting and feed through a high-precision and rigid lathe and finely sharpened tools, obviously, This process is able to significantly improve the accuracy of CNC machined parts.

The difference between roughing and finishing of CNC lathes

The difference between roughing and finishing of CNC lathes is that one is rough machining and the other is fine machining, and the latter pays more attention to details than the former. Rough machining is for the purpose of quickly cutting off the remaining surface of CNC machined parts, so as to achieve as much cutting as possible in a short period of time. The dimensional accuracy and surface quality of CNC machined parts are relatively low. The purpose of finishing is to cut thin metal materials on the surface of the workpiece to obtain higher precision and surface quality.

When roughing, the choice of cutting amount is generally based on improving the production efficiency of CNC machining, followed by economy and processing cost. Therefore, when considering the cutting amount of roughing, we should try to choose a larger cutting amount within the allowable range, followed by a larger feed rate, and then a smaller cutting speed. When finishing machining, the choice of cutting amount is mainly to ensure the quality of CNC machining, followed by improving production efficiency and tool life. Therefore, when considering the cutting amount of finishing, generally choose a smaller amount of cutting tool, and then choose a smaller feed amount, and you can choose a larger cutting speed.

What is the difference between roughing and finishing of CNC lathes? After browsing the above articles, you can find that the difference between roughing and finishing of CNC lathes is that one is rough machining and the other is fine machining. Rough machining removes a lot of material, feed rate and cutting knife The amount is relatively large, the cutting speed is relatively small, and the dimensional accuracy and surface quality of the workpiece processed by CNC are relatively low. Less material is removed by finishing, the feed rate and cutting amount are relatively small, the cutting speed is relatively large, and the dimensional accuracy and surface quality of the parts processed by CNC are high.

Conclusion

In conclusion, rough CNC machining and fine CNC machining are two distinct stages within the CNC machining process. Rough machining focuses on efficient material removal, while fine machining emphasizes precision and achieving the desired dimensions and surface finishes. Understanding the differences between these processes is essential for optimizing CNC machining operations and producing high-quality components with accuracy and efficiency.

The above is the summary of VMT CNC machining manufacturers. If you want to know more about the knowledge and application of CNC machining, please contact us to discuss with me.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!