15 years one-stop China custom CNC machining parts factory

197 |

Published by VMT at Nov 06 2025 | Reading Time:About 3 minutes

197 |

Published by VMT at Nov 06 2025 | Reading Time:About 3 minutes

CNC machining offers automated precision, complex part capabilities, and superior repeatability, while traditional machining relies on manual skill for simpler tasks, highlighting key machining differences.

In today's dynamic manufacturing landscape, choosing the right machining method is a strategic decision that directly impacts product quality, cost, and time-to-market. The increasing demands for precision, speed, and design complexity require manufacturers to carefully evaluate their options.

For engineers and procurement specialists, understanding the fundamental machining differences between CNC (Computer Numerical Control) machining and traditional machining is crucial. This knowledge empowers you to make informed choices, ensuring your project aligns with the most efficient and effective manufacturing process available.

This comprehensive guide will delve into these distinctions, providing you with the insights needed to leverage the full potential of advanced manufacturing.

Traditional machining refers to a broad category of subtractive manufacturing processes where material is removed from a workpiece using manually operated tools and machinery. It forms the historical foundation of modern manufacturing techniques.

These methods rely heavily on the direct physical interaction and control of a skilled operator. They are fundamental processes that have shaped industries for centuries.

Manual Control and Operator Skill

At the heart of traditional machining lies direct human control over the machine's movements. Operators manually adjust levers, turn cranks, and guide tools to shape the material according to engineering drawings.

This manual operation demands immense skill, experience, and precision from the machinist. The quality and accuracy of the final part are heavily dependent on the individual operator's expertise and attention to detail.

Common Traditional Methods Explained

Traditional machining encompasses several well-known processes, each suited for specific tasks. These methods include turning, milling, drilling, and grinding.

Traditional turning uses a lathe where the workpiece rotates against a stationary cutting tool, typically for cylindrical parts. Traditional milling employs a rotating cutter to remove material from a stationary workpiece, creating flat surfaces or complex shapes.

Drilling involves creating holes, while grinding uses abrasive wheels for fine finishing and high accuracy. Each method has specific applications where it remains effective.

Best Use Cases and Limitations

Traditional machining excels in low-volume production, prototyping, and when unique, one-off parts are required. It offers flexibility in setup and can be cost-effective for simple geometries without stringent tolerance requirements.

However, its limitations become apparent with complex designs, high-volume production, or when extremely tight tolerances and repeatability are critical. Human fatigue and varying skill levels can lead to inconsistencies and higher scrap rates in these scenarios.

CNC Machining, or Computer Numerical Control machining, represents a paradigm shift in manufacturing, leveraging computer automation to direct machine tools. This technology has revolutionized precision manufacturing.

It brings a new level of accuracy, speed, and complexity to the production of parts across virtually every industry. This transformation addresses many of the limitations inherent in traditional manual methods.

Automation and Computer Control

Unlike traditional methods, CNC machining operates through pre-programmed computer instructions. These digital instructions, often generated from CAD/CAM software, dictate every movement of the machine tools.

The machine interprets these codes to control tool paths, feed rates, spindle speeds, and other critical parameters with extreme precision. This automation minimizes human intervention during the actual machining process, leading to consistent results.

Types of CNC Machines and Capabilities

The world of CNC machining is diverse, featuring various machine types designed for specific capabilities. Common examples include CNC mills, lathes, routers, grinders, and even EDM (Electrical Discharge Machining) machines.

CNC milling is particularly versatile, capable of producing complex 3D shapes. Multi-axis CNC machines (3-axis, 4-axis, 5-axis) offer enhanced capabilities, allowing for machining on multiple sides of a part without re-fixturing. This significantly increases efficiency and design freedom for custom CNC machining.

Key Benefits for Modern Manufacturing

The benefits of CNC machining are profound for modern industries. It enables the production of parts with exceptional accuracy, superior surface finishes, and unparalleled repeatability.

CNC machining services also allow for the rapid prototyping and efficient mass production of complex geometries that would be impossible or cost-prohibitive with traditional methods. This technology drives innovation and ensures high-quality parts.

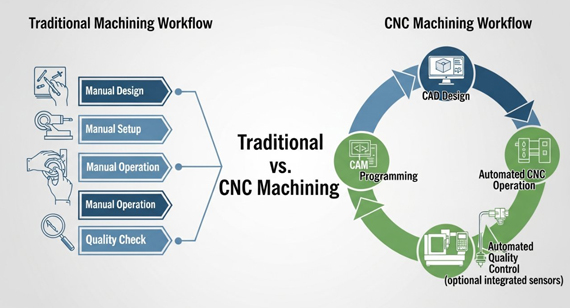

Understanding the operational contrasts between CNC and traditional machining is fundamental to appreciating their respective roles. These differences permeate every stage, from initial setup to final output.

The method of control and the underlying intelligence guiding the cutting tools dictate the efficiency and outcomes of the entire process. This distinction profoundly affects project timelines and manufacturing capabilities.

Setup and Programming Contrasts

Traditional machining setup often involves manually aligning tools and workpieces, relying on physical measurements and operator intuition. Each new part or adjustment requires hands-on calibration.

CNC machining, in contrast, begins with digital programming. CAD models are translated into G-code or M-code, which precisely instructs the machine. While initial programming can be intensive, it allows for quick, repeatable setups once validated, especially for custom CNC machining.

| Feature |

Traditional Machining |

CNC Machining |

| Control Method |

Manual, operator-driven | Automated, computer-programmed (G-code) |

| Setup Time |

Faster for simple, one-off parts | Slower initial programming, faster for repeats |

| Tool Alignment |

Manual, relies on operator skill | Programmed, precise digital alignment |

| Adjustments |

Physical adjustments during operation | Software parameter changes, minimal physical adjustment |

Production Speed and Throughput

Traditional machining's production speed is inherently limited by manual operation, including loading, cutting, and quality checks. Each cycle requires direct human intervention and time.

CNC machining drastically increases throughput. Once programmed, machines can operate continuously, often with minimal supervision, leading to much faster production cycles and higher volumes of CNC machining parts. This automation is a cornerstone of efficient precision manufacturing.

Human Error Versus Machine Consistency

In traditional machining, human error is an unavoidable factor. Fatigue, minor miscalculations, or slight variations in technique can lead to inconsistencies between parts, impacting overall quality.

CNC machining virtually eliminates human error from the cutting process itself. The machine follows programmed instructions flawlessly, ensuring extremely high consistency and repeatability across every part produced. This reliability is critical for high-quality parts.

The ability to consistently produce parts within specified tolerances, achieve desired surface finishes, and maintain uniformity across production runs are hallmarks of advanced manufacturing. This is where CNC machining truly excels over traditional methods.

These aspects are critical differentiators, especially when considering applications demanding the highest standards of engineering and performance. High-quality parts are non-negotiable in many industries.

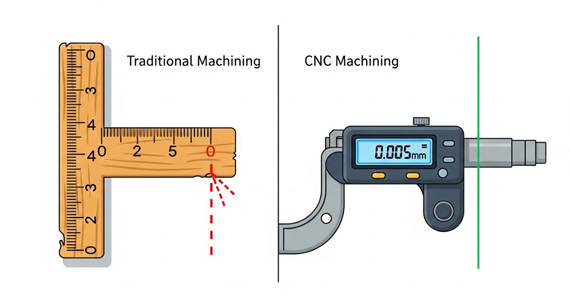

Achieving Tighter Tolerances

Traditional machining is typically limited by the operator's dexterity and the inherent backlash in manual machine components. Achieving tolerances tighter than ±0.001 inch can be challenging and inconsistent.

CNC machining, driven by computer control and precise servo motors, routinely achieves tolerances as tight as ±0.0002 inches (±5 microns) or even finer. This capability is vital for precision manufacturing, allowing for perfectly fitting components.

| Aspect |

Traditional Machining |

CNC Machining |

| Typical Tolerance |

±0.001" to ±0.005" | ±0.0002" to ±0.001" (and tighter) |

| Factors Limiting |

Operator skill, machine wear | Machine rigidity, environmental control |

| Consistency |

Varies with operator skill | Highly consistent, programmed accuracy |

| Measurement |

Manual, post-machining | Often in-process probing, automated |

Surface Finish and Part Integrity

The surface finish quality in traditional machining can vary greatly. Factors like tool sharpness, feed rate, and operator technique all influence the final texture and appearance of the part.

CNC machining offers superior and more consistent surface finishes. Programmed tool paths, optimized cutting parameters, and advanced tooling result in smoother surfaces and better overall part integrity, reducing the need for secondary finishing operations. This is crucial for aesthetic and functional integrity of CNC machining parts.

Uniformity Across Production Batches

Maintaining uniformity across a large batch of parts is a significant challenge for traditional machining. Even the most skilled operator will introduce minor variations from one piece to the next.

CNC machining ensures near-perfect uniformity across entire production batches. Once a program is validated, every subsequent part produced will be an exact replica, meeting the same precise specifications. This consistency is a cornerstone of reliable precision manufacturing.

Analyzing the true cost and efficiency of machining methods goes beyond initial setup; it encompasses labor, material usage, and long-term production. The choice between CNC and traditional profoundly impacts a project's financial viability.

Understanding these economic factors is crucial for making strategic decisions, especially for businesses looking for cost-effective solutions and high-quality parts. Transparency in pricing is also key.

Initial Investment vs. Long-Term Savings

The initial investment for traditional machines is generally lower, making them accessible for smaller workshops or hobbyists. However, these savings often diminish quickly in a production environment.

CNC machines represent a higher upfront capital investment. Yet, their efficiency, speed, reduced labor needs, and minimal scrap rates translate into significant long-term savings, particularly for medium to high-volume production of CNC machining parts.

Labor Costs and Overhead

Traditional machining is labor-intensive, requiring highly skilled operators for constant direct supervision and manipulation. This translates to higher per-part labor costs, especially for complex or repetitive tasks.

CNC machining significantly reduces labor costs. Once programmed, a single operator can oversee multiple machines, or machines can run unattended for extended periods. This lowers overhead and increases profitability for CNC machining services.

Material Waste and Optimization

Manual operations in traditional machining inherently carry a higher risk of material waste due to operator errors or less optimized cutting paths. Mistakes can render expensive raw materials unusable.

CNC machining programs are designed to optimize material usage, calculating the most efficient cutting paths to minimize waste. This precision reduces scrap rates and contributes to lower overall production costs, especially for valuable materials used in precision manufacturing.

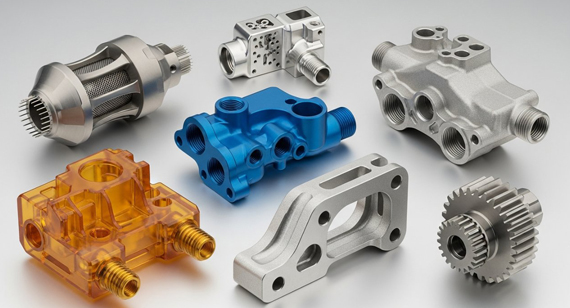

The modern manufacturing landscape demands the ability to create increasingly intricate designs from a wider array of materials. This is another area where CNC machining opens up possibilities far beyond traditional methods.

The freedom to innovate without being constrained by manufacturing limitations is invaluable. From prototyping to mass production, the capabilities in this realm are a key differentiator for high-quality parts.

Intricate Geometries and Features

Traditional machining struggles with complex geometries, undercuts, and internal features that require multiple setups or specialized, custom tooling. These designs are often time-consuming and expensive to produce manually.

CNC machining excels at creating highly intricate and complex geometries with ease. Multi-axis CNC milling, in particular, can produce elaborate 3D shapes, organic forms, and internal features in a single setup, offering unparalleled design freedom for custom CNC machining.

Machining Challenging Materials

While traditional machines can handle a range of materials, machining very hard alloys, ceramics, or composites often presents significant challenges. Tool wear, heat generation, and maintaining accuracy become difficult.

CNC machines are equipped to handle a vastly wider range of challenging materials, including aerospace-grade titanium, high-strength steels, superalloys, and advanced plastics. Optimized cutting parameters and specialized tooling ensure efficient and accurate machining of these materials for high-quality parts.

From Prototyping to Mass Production

Traditional machining is often used for simple prototypes due to its quick setup for one-off jobs. However, scaling up to mass production is inefficient and costly, with consistency issues.

CNC machining offers seamless scalability from rapid prototyping to high-volume mass production. A validated program for a prototype can be directly used for thousands of parts, ensuring consistent quality and efficiency throughout the entire product lifecycle. This makes CNC machining services ideal for all stages.

Selecting the right manufacturing partner is as critical as choosing the right machining method. A reliable partner ensures your project's success, delivering both technical expertise and high-quality parts.

For many businesses, leveraging external expertise for CNC machining services offers a strategic advantage. It allows you to access advanced capabilities without the significant capital investment.

Assessing Project Requirements

Before engaging a partner, clearly define your project's specific requirements. Consider factors such as part complexity, material choice, tolerance specifications, production volume, and desired lead times.

These parameters will dictate whether CNC machining is the optimal solution and help identify a manufacturer with the right capabilities. Understanding your needs is the first step towards successful custom CNC machining.

The Value of a Source Manufacturer

Partnering with a source manufacturer like VMT CNC machining parts services factory provides distinct advantages. We possess direct control over the entire production process, ensuring consistent quality and accountability.

Working directly with a factory eliminates intermediaries, often leading to better communication, faster problem-solving, and more competitive transparent pricing. Our deep technical expertise ensures your designs are realized to the highest standards.

Transparent Pricing and Technical Support

A reputable machining partner provides clear, transparent pricing structures from the outset. You should understand how costs are broken down and what you are paying for, avoiding hidden fees.

Furthermore, expect robust technical support. Our engineers can provide valuable DFM (Design for Manufacturability) insights, helping optimize your designs for efficient and cost-effective CNC machining. This ensures you get the best high-quality parts.

Ensuring High-Quality Parts

The ultimate goal is to receive high-quality parts that meet or exceed your specifications. A trusted partner will have stringent quality control protocols, including in-process inspections and final quality assurance checks.

Ask about certifications (e.g., ISO, AS9100) and their quality management system. At VMT, our commitment to precision manufacturing means every CNC machining part undergoes rigorous testing to guarantee performance and reliability.

Problem: A medical device startup approached VMT with a critical challenge: they needed to rapidly prototype and then scale production for a new, highly complex surgical instrument component. Their existing supplier, using traditional methods, struggled with consistent tolerances, material compatibility (surgical-grade titanium), and could not meet the aggressive launch timeline. The parts were experiencing subtle deformities, making them unusable.

Our Solution: VMT's team of expert engineers collaborated closely with the startup, leveraging our advanced CNC machining services. We analyzed their CAD files, providing DFM recommendations to optimize the design for 5-axis CNC milling without compromising functionality. Our state-of-the-art multi-axis CNC machines were precisely programmed to machine the surgical-grade titanium, ensuring tight tolerances (±0.0005 inches) and superior surface finish in a single setup. We implemented in-process quality checks and robust post-machining verification.

Result: By utilizing VMT's precision manufacturing capabilities and our transparent pricing model, the startup received their initial prototype batch ahead of schedule, with every single part meeting stringent medical industry specifications. The consistent quality and rapid turnaround allowed them to secure critical regulatory approvals faster. Subsequently, we transitioned seamlessly into mass production, delivering thousands of high-quality CNC machining parts consistently, enabling the startup to successfully launch their innovative surgical instrument to market.

Ready to elevate your product's performance and streamline your manufacturing process? Leverage our deep technical expertise and transparent pricing. Contact us today for a personalized consultation and a precise quote for your next high-quality part CNC project.

What is CNC machining exactly?

CNC machining is a subtractive manufacturing process that uses pre-programmed computer software to control the movement of machine tools. This automation allows for precise and repeatable production of parts with complex geometries and tight tolerances.

How does CNC differ from traditional methods?

The primary difference lies in control. Traditional machining relies on manual operator skill, while CNC machining uses computer programs for automated, highly precise control over tool paths and movements.

Is traditional machining still relevant today?

Yes, traditional machining remains relevant for specific applications, such as one-off prototypes, very low-volume production, or simple parts where ultra-high precision is not critical. It is also valuable for basic repairs.

What materials can CNC machines process?

CNC machines can process a vast range of materials. This includes metals like aluminum, steel, titanium, brass, and copper, as well as plastics such as ABS, Nylon, Polycarbonate, and composite materials, ensuring high-quality parts.

What are the main benefits of CNC machining?

The main benefits include high precision and accuracy, excellent repeatability, the ability to produce complex geometries, faster production speeds, and reduced labor costs. It's ideal for precision manufacturing.

Is CNC machining more expensive than traditional?

Initially, CNC machines have a higher capital cost. However, for medium to high-volume production, their efficiency, speed, reduced labor, and minimized material waste often make them more cost-effective in the long run.

Can CNC handle custom projects?

Yes, custom CNC machining is one of its core strengths. It excels at producing bespoke parts, intricate designs, and specialized components based on unique customer specifications, from prototyping to full production.

Why choose VMT for CNC machining services?

VMT offers deep technical expertise as a source manufacturer, transparent pricing, stringent quality control for high-quality parts, and comprehensive technical support. We ensure precision manufacturing for all your CNC machining needs.