15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

115 |

Published by VMT at Jan 10 2022

115 |

Published by VMT at Jan 10 2022

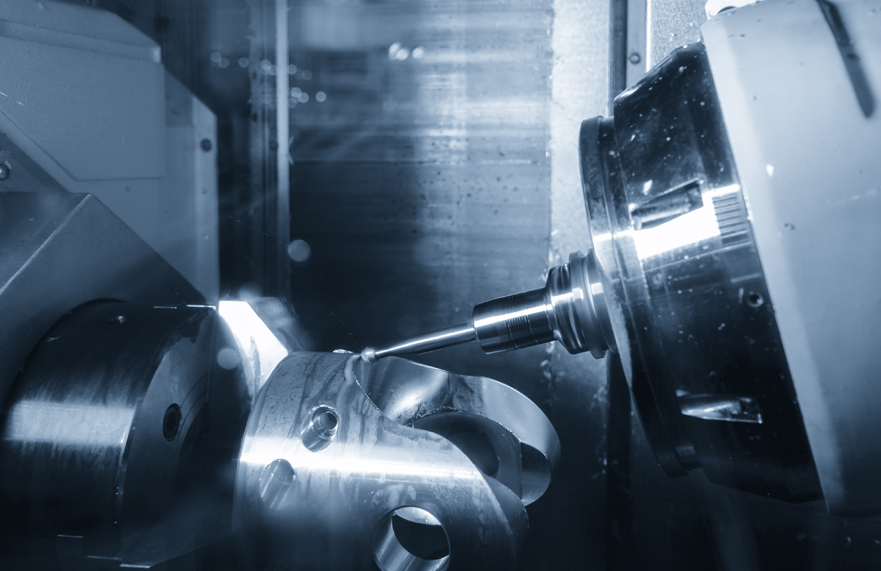

The precision CNC machined parts of the aluminum alloy shell have the characteristics of light weight and exquisite appearance and structure, which are very popular in various industries, and are more and more widely used in the field of industrial and daily necessities. Especially in recent years, with the development of science and technology and the progress of society, people's demand for the diversity of aluminum precision CNC machining parts is getting stronger and stronger. Therefore, the processing technology requirements of aluminum precision CNC machining parts are getting higher and higher, which is very favored by people, the market demand is also increasing, and the benefits are higher. CNC machining is one of the best CNC machining methods for aluminum precision CNC machining parts.

In order to meet people's demand for the diversity and high-quality CNC machining of aluminum precision CNC machining parts, it is necessary to summarize CNC machining process skills in the CNC machining process. VMT summarizes the aluminum precision CNC machining parts based on years of CNC machining experience. CNC machining skills.

The technical requirement of aluminum precision CNC machining parts is to control the CNC machine tool system, logically process the programs with control codes or other symbolic instructions, and decode them through the computer, so that the CNC machine tools can operate and process parts quickly. The raw material is processed into semi-finished or finished parts by CNC machining tool cutting.

CNC machining cutting is a numerical control machining method that makes cutting more rational, and it is also a common machining process for aluminum precision CNC machining parts. It selects the appropriate CNC machining tool to machine the hole.

The ball end mill combined with the helical interpolation method can continuously process the taper hole; the ball end mill and the drill bit with helical interpolation can be used for boring and chamfering; the end mill combined with the equal-height insertion interpolation , semi-finishing and precision CNC parts processing can be performed on holes; end mills for CNC thread machining with helical interpolation method can process various threaded holes.

If high-efficiency aluminum precision CNC parts are processed for high-precision holes of any size, the tool interpolation function can be used. Especially when high-speed milling is used, the load on each tooth is relatively light, so the same coated carbide end mill can be used for high-speed and high-precision hole machining of various materials. With the improvement of living standards, the quality of life has changed by leaps and bounds. Many people are thinking about how to improve the quality of aluminum precision CNC machining parts. The technology and benefits are getting higher and higher, and the market demand is also increasing. Customers are interested in CNC machining. requirements are getting higher and higher. What are the specific technical requirements for aluminum precision CNC machining parts?

1) Reasonably select the cutting amount, and the operator selects the cutting speed to be used according to the required material, hardness, cutting state, material type, and cutting depth. These conditions are ideal for effectively protecting the machine from wear and tear.

2) Choose the right tool. When rough CNC machining, generally choose a tool with high strength and durability, which can better meet the requirements of rough turning.

3) Choose a reasonable fixture. CNC machining parts should fully meet the needs of CNC machining machines to reduce unnecessary positioning errors, and select special fixtures and clamping tools.

4) Before working, it is necessary to determine the CNC machining route, and try to shorten the machining route to reduce the wear and tear of the CNC machining machine tool and cause damage to the machine tool.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!