15 years one-stop China custom CNC machining parts factory

VMT has been helping numerous customers across various industries realize their manufacturing and prototyping needs and requirement. Explore our successful cases below.

Get an Instant QuoteBraces are very common in the machining of mechanical parts. Why do you need braces? What are the benefits of product braces? In the cnc machining of mechanical parts, the braces are threaded insert. After the threads are processed, the threaded insert are installed on the threads. With so many CNC machining factories, how should we choose?

66

66

Read more

Read more

Hard surface treatment has obvious effects in the manufacturing process, but the surface of the product that has undergone hard surface inspection is more wear-resistant and oxidation-resistant, which is very important for the aviation drone components manufacturing industry.

66

66

Read more

Read more

There are many surfaces that require cnc machining of the shell and box, such as medical boxes, gear boxes, etc. Among these machined surfaces, plane machining accuracy is easier to ensure than hole machining accuracy.

66

66

Read more

Read more

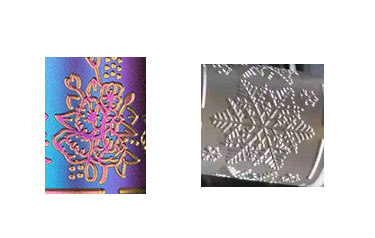

For this electronic product shell, the customer needs 100,000 shells of 4 colors in order to catch a certain festival. VMT arranges special personnel to follow up the oxidation plant to control the color difference to meet the needs of customers.

66

66

Read more

Read more

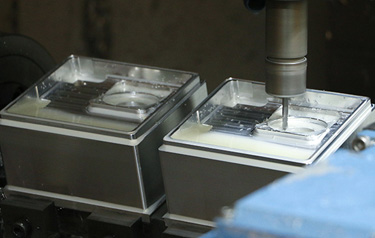

In December, a Norwegian customer found us through a Google search for a CNC machining titanium alloy flashlight shell factory. They developed a titanium alloy flashlight shell.

66

66

Read more

Read more

After receiving this project, our engineers have been studying how to give the best solution to this project in terms of processing technology. The details of each part of the 19 parts are according to the details of the engineering drawings. We have developed with the customer for 3 months.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!