15 years one-stop China custom CNC machining parts factory

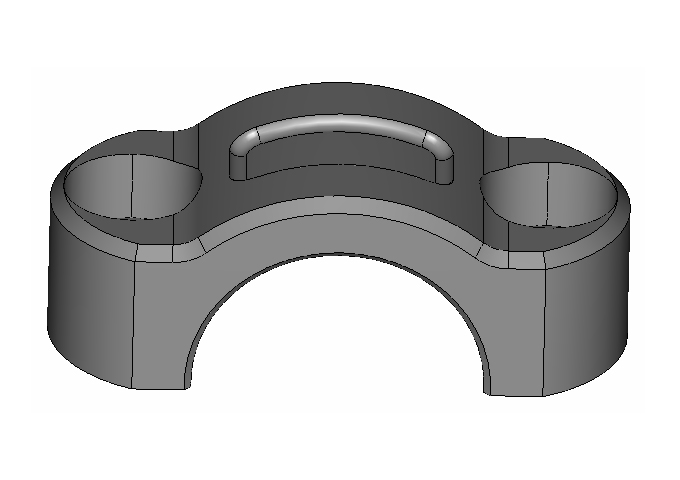

CNC Machining Case for the Upper Cover of Motorcycle Brake Parts for Ltalian Customers

Customer requirements: Assembly and cooperation can not be misaligned

Quantity: 2500 pieces

Material: Aluminum Alloy 6061-T6

CNC machining method: Extrusion + CNC machining

Delivery time:15 days

Some time ago, the VMT website received an inquiry about CNC machining of the upper cover of Italian motorcycle brake parts. Although this product is an appearance part, the arc R angle of the upper cover of the motorcycle brake part needs to be beautiful and also a functional part. The bearing connection needs to be guaranteed. The bearings are tightly matched to ensure dimensional accuracy and assembly cannot be misaligned.

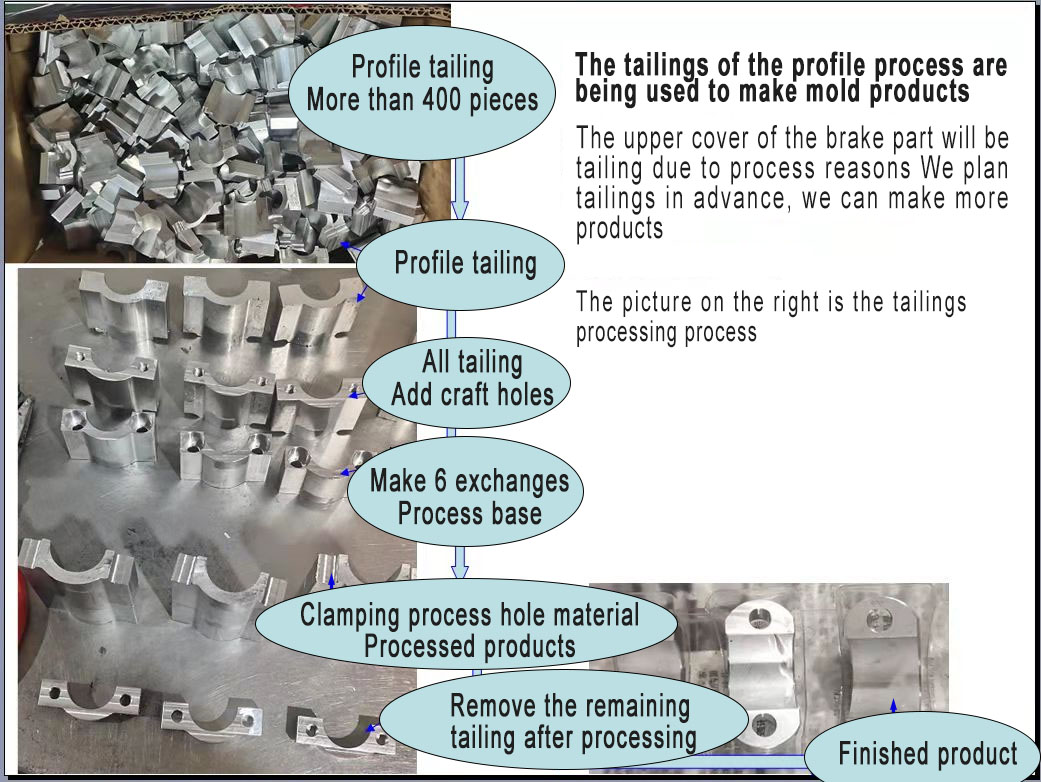

After signing the confidentiality agreement, the customer sent us 3d drawings, VMT engineering and business communicated in detail the technical requirements of the Italian customer, and our business relayed the CNC machining plan for the upper cover of the motorcycle brake parts to the customer. The customer agreed with it and finally decided to use the profile tailings for processing. The tailings are all CNC machined with holes, 6 interchangeable craft seats are made, and the process holes are locked for CNC machining parts. After processing, the remaining tails are removed, and the profile process tails The material is reused, and a mold part is made.

There is a tail material on the upper cover of motorcycle brake parts due to process reasons. The project planned the tail material in advance to make one more part. It needs to make auxiliary process holes and process seats, which reduces the customer's CNC machining costs and achieves the Customer's CNC machining process requirements and delivery time.

In order to better meet the needs of customers and let them rest assured in the process of customizing CNC machining parts, VMT precision CNC machining factory can provide customers with prototype processing, and WeChat engineering, business, production 24-hours "3+1" service, anytime Follow up the progress of the CNC machining parts, the cooperation is easy and pleasant, and there will be no conflicts and contradictions.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!