15 years one-stop China custom CNC machining parts factory

Home / Product / Electronic Industry /

VMT is a CNC machining and manufacturing factory for various electronic equipment casings. With 13 years of experience in CNC machining electronic housings and various types of CNC electronic housing samples, you can send pictures to view and view the factory online, contact us immediately to obtain samples. We can provide you with various types of electronic product casing machining services to meet your customized CNC machining needs.

Product Specification:

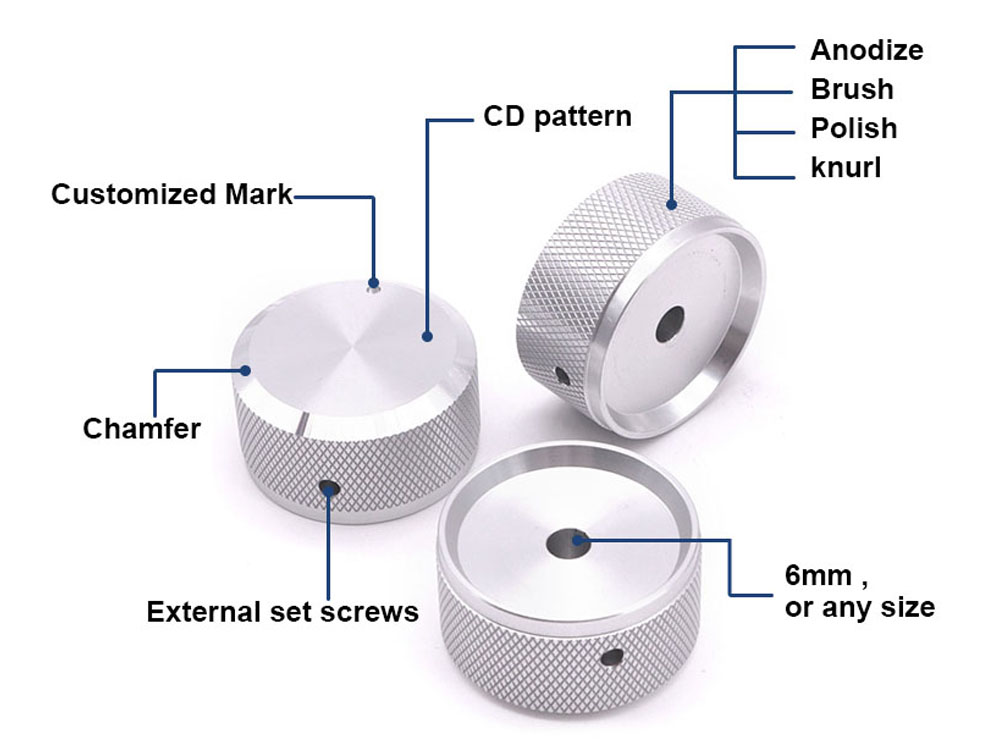

Custom CNC Machining Aluminum Stainless Steel Brass knurled Audio Volume Control Knobs

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

Custom CNC knurled Audio Volume Control Knobs Services Manufacturer

| When it comes to custom CNC knurled audio volume control knobs, finding a reliable manufacturing partner is crucial. As a leading CNC prototyping and manufacturing company, we specialize in providing high-quality custom CNC knurled audio volume control knobs tailored to your specific requirements. With expertise in CNC prototyping, a wide range of materials, and various surface treatments, we offer comprehensive solutions to meet your manufacturing needs. |

Custom CNC knurled Audio Volume Control Knobs Prototyping Machining

Our CNC prototyping service allows you to visualize and test your custom CNC knurled audio volume control knob before going into series production. Accurately and efficiently create prototypes according to your design specifications. Through CNC prototyping, we enable you to verify the design, function and ergonomics of custom knobs, ensuring they meet your expectations. |

|

|

|

|

||

Custom CNC knurled Audio Volume Control Knobs Surface Treatment |

Custom CNC knurled Audio Volume Control Knobs Material |

||

|

As a custom CNC fabrication solutions provider, we offer a wide range of materials to meet your specific requirements and preferences. Determine the most suitable material for your custom CNC knurled audio volume control knob, taking into account factors such as function, aesthetics and budget. |

To further enhance the functionality and aesthetics of your custom CNC knurled audio volume control knob, we offer a variety of finishes. to ensure they complement the material and design of your custom CNC knurled audio volume control knobs for a high-quality look that is visually appealing. |

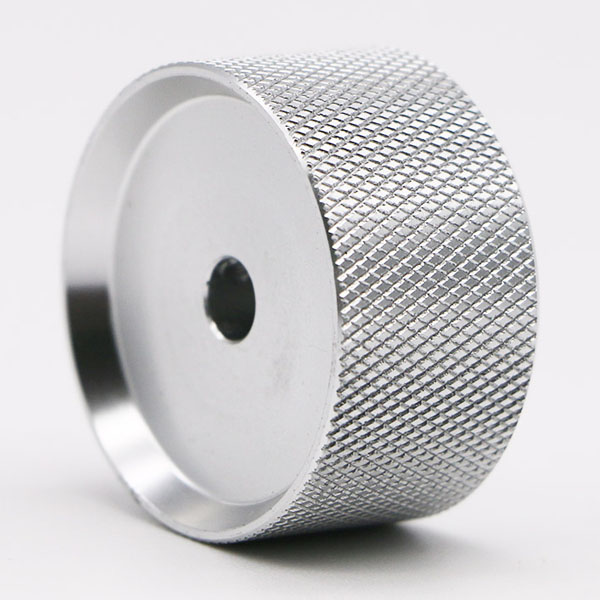

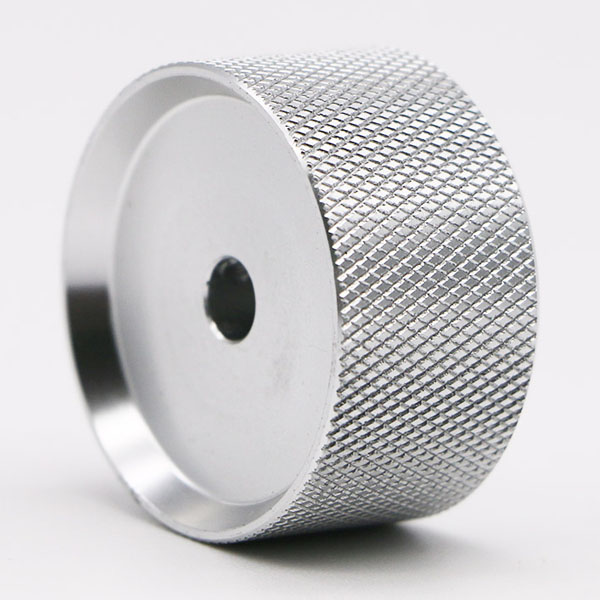

Custom CNC Knurled Audio Volume Control Knobs Parts Sample

|

|

|

||

|

|

|||

|

|

|

||

|

|

|||

|

|

|

| Custom CNC knurled audio volume control knobs are essential components of audio equipment, providing users with precise control and an enhanced user experience. When it comes to manufacturing these knobs, choosing the right material is crucial. Each material offers unique properties that impact the functionality, durability, and aesthetics of the knobs. |

|

|

Aluminum CNC Knurled Audio Volume Control Knobs

Aluminum: Aluminum is a popular choice for custom CNC knurled audio volume control knobs due to its excellent combination of strength, lightness, and corrosion resistance. It offers several advantages, including:

Lightweight: Aluminum knobs are lightweight, reducing the overall weight of the audio equipment and providing a comfortable user experience.

More Details>> |

|

|

|

Brass CNC Knurled Audio Volume Control Knobs

Brass: Brass knobs are known for their timeless elegance and classic appearance. Here are the benefits of using brass for custom CNC knurled audio volume control knobs:

Sophistication: Brass knobs add a touch of sophistication and luxury to audio equipment, making them suitable for high-end or vintage-inspired designs.

More Details>> |

|

|

|

Stainless Steel CNC Knurled Audio Volume Control Knobs

Stainless Steel: Stainless steel is a robust and corrosion-resistant material that offers several advantages for custom CNC knurled audio volume control knobs:

Durability: Stainless steel is highly durable and resistant to scratches, impacts, and harsh environmental conditions, ensuring the longevity of the knobs.

More Details>> |

|

|

|

Plastic CNC Knurled Audio Volume Control Knobs

Plastic: Plastic knobs are cost-effective, lightweight, and versatile options for custom CNC knurled audio volume control knobs. Here are the benefits of using plastic:

Affordability: Plastic knobs are more budget-friendly compared to metal options, making them suitable for cost-conscious projects.

More Details>> |

|

| When selecting the material for custom CNC knurled audio volume control knobs, it is essential to consider factors such as durability, aesthetics, weight, and customization options. Aluminum, brass, stainless steel, and plastic offer distinct advantages and characteristics that cater to different design preferences and functional requirements. By choosing the right material, you can ensure that your custom knobs not only provide precise control but also enhance the overall look and feel of your audio equipment. |

|

Custom CNC knurled audio volume control knobs play a vital role in audio equipment, offering precise control and enhancing the user experience. In addition to choosing the right material, surface treatments are essential for improving functionality, aesthetics, and durability. |

|

1. Anodizing

Anodizing is a popular surface treatment for custom CNC knurled audio volume control knobs, particularly for those made of aluminum. It involves an electrochemical process that forms a protective oxide layer on the surface of the knobs. Here are the advantages of anodizing: Corrosion Resistance: Anodizing enhances the natural corrosion resistance of aluminum, making the knobs more durable and suitable for various environments.

|

|

|

2. Powder Coating

Powder coating is another popular surface treatment that can be applied to custom CNC knurled audio volume control knobs made of different materials, including aluminum, brass, and steel. It involves applying a dry powder to the knobs and then curing them to create a durable and attractive finish. Here are the benefits of powder coating:

Durability: Powder-coated knobs have excellent resistance to scratches, impacts, and chemicals, ensuring long-lasting performance.

|

|

|

|

3. Polishing

Polishing is a surface treatment that enhances the visual appeal of custom CNC knurled audio volume control knobs, particularly for materials like brass and stainless steel. Here's why polishing is a popular choice:

Mirror-like Finish: Polished knobs have a reflective surface that adds a touch of elegance and sophistication to audio equipment.

|

|

|

|

Surface treatments are crucial for custom CNC knurled audio volume control knobs as they not only enhance the functionality and durability but also contribute to the overall aesthetics of the knobs. Anodizing, powder coating, and polishing are just a few examples of surface treatments that can transform the appearance and performance of your knobs. By selecting the right surface treatment based on your material choice and design goals, you can create custom knobs that are visually appealing, durable, and tailored to your specific requirements. |

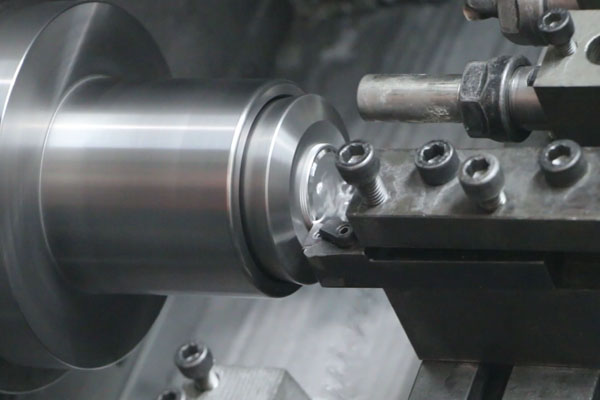

| Custom CNC knurled audio volume control knobs are precision-engineered components that require a meticulous manufacturing process to ensure their quality and functionality. We will guide you through the step-by-step process of manufacturing custom CNC knurled audio volume control knobs, from initial design to the final product. |

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

1. Design and Prototyping

Design and Prototyping: The manufacturing process begins with the design and specification of the custom CNC knurled audio volume control knobs. This involves determining the dimensions, features, and aesthetic details of the knobs. CAD software is often used to create a 3D model of the design, allowing for precise measurements and visualization. |

|

Once the design is finalized, the appropriate material is selected based on the desired characteristics and performance of the knobs. Common materials used for custom CNC knurled audio volume control knobs include aluminum, brass, stainless steel, and plastic. The material choice impacts factors such as weight, durability, and aesthetics. |

|

3. CNC Machining

CNC machining is the core process used to manufacture custom CNC knurled audio volume control knobs. The 3D design is translated into instructions that guide the CNC machine to precisely shape the raw material. The CNC machine removes excess material through cutting, drilling, and milling, creating the desired shape and features of the knobs. |

|

4. Knurling

|

|

After the CNC machining and knurling processes, the custom CNC knurled audio volume control knobs undergo surface treatment to enhance their appearance and durability. Surface treatments such as anodizing, powder coating, or polishing are applied, depending on the material and desired aesthetic. These treatments protect the knobs from corrosion, scratches, and wear. |

|

5. Quality Control

Quality Control: Quality control is an integral part of the manufacturing process. Each batch of custom CNC knurled audio volume control knobs is carefully inspected to ensure they meet the specified requirements. This includes checking for dimensional accuracy, surface finish, knurling quality, and functionality. Any defects or deviations are identified and addressed to maintain the highest quality standards. |

| Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

|

6. Packaging and Delivery

Once the custom CNC knurled audio volume control knobs pass the quality control stage, they are carefully packaged to protect them during transportation. The packaging is designed to prevent damage and ensure that the knobs reach their destination in optimal condition. The knobs are then ready for delivery to the customer or the next stage of the supply chain. |

|

The manufacturing process of custom CNC knurled audio volume control knobs involves multiple stages, from design and material selection to CNC machining, knurling, surface treatment, and quality control. Each step is crucial to ensure the production of high-quality knobs that meet the specifications and requirements of the customers. By following a precise and detailed manufacturing process, manufacturers can deliver custom CNC knurled audio volume control knobs that provide precise control, durability, and a superior user experience. |

Custom CNC Knurled Audio Volume Control Knobs Industry Applications

|

Custom CNC knurled audio volume control knobs find extensive applications across various industries where precise control of audio volume is essential. These knobs are designed to offer functionality, durability, and aesthetic appeal, making them a popular choice in different sectors. |

|

1. Audio Equipment Manufacturing

2. Professional Audio Systems

3. Broadcast and Recording Studios

4. Automotive Industry

5. Aviation and Aerospace

6. Medical and Healthcare Equipment

7. Industrial Machinery

8. Consumer Electronics

9. Gaming and Entertainment Systems

10. Musical Instruments

|

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom CNC Knurled Audio Volume Control Knobs FAQs

Here are some commonly asked questions about custom CNC knurled audio volume control knobs:

|

Q: What are custom CNC knurled audio volume control knobs?

Q: What materials are commonly used for custom CNC knurled audio volume control knobs?

Q: Can I choose the color and finish of my custom CNC knurled audio volume control knobs?

Q: How can I ensure a comfortable grip on custom CNC knurled audio volume control knobs?

Q: Are custom CNC knurled audio volume control knobs compatible with all audio equipment?

Q: Can I request a specific logo or labeling on custom CNC knurled audio volume control knobs?

Q: Are custom CNC knurled audio volume control knobs easy to install?

Q: Can I order custom CNC knurled audio volume control knobs in small quantities?

Q: How do I request a quote or place an order for custom CNC knurled audio volume control knobs?

Q: Are custom CNC knurled audio volume control knobs compatible with both professional and consumer audio equipment?

If you have any further questions or specific inquiries about custom CNC knurled audio volume control knobs, feel free to contact the manufacturer or supplier for personalized assistance. |

Custom CNC Lathe Turning M3 M4 M5 astener Knurled Thumb Lead Free Brass Threaded Insert Nut

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.