15 years one-stop China custom CNC machining parts factory

Home / Product / Electronic Industry /

VMT is a CNC machining and manufacturing factory for various electronic equipment casings. With 13 years of experience in CNC machining electronic housings and various types of CNC electronic housing samples, you can send pictures to view and view the factory online, contact us immediately to obtain samples. We can provide you with various types of electronic product casing machining services to meet your customized CNC machining needs.

Product Specification:

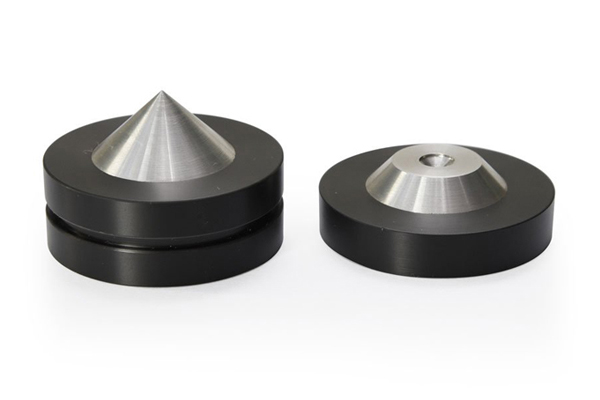

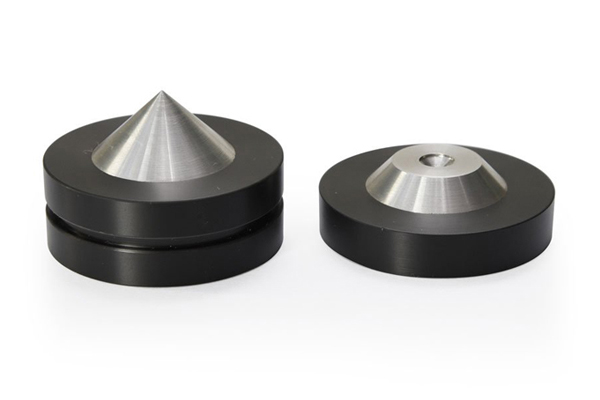

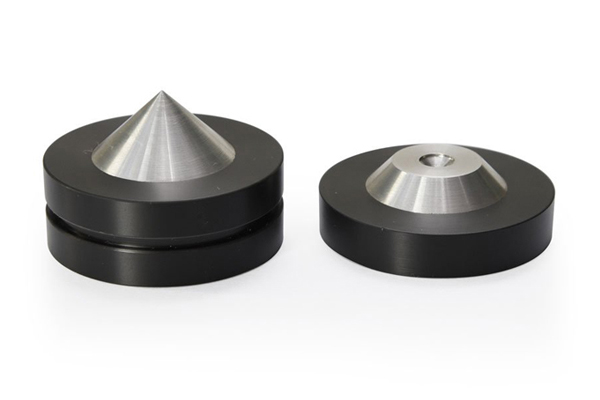

Custom CNC Machining Golden Speaker Spikes Subwoofer CD Audio Amplifier Turntable Isolation Stand Feet Shoes

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

Our Custom CNC Machining Speaker Spikes Feet Shoes Services Manufacturer

| We are a professional custom CNC machining speaker spikes feet shoes manufacturer, we can custom manufacture a variety of complex design parts, provide you with drawing design analysis and prototype manufacturing, material selection, surface treatment. There are professional engineers to provide you with guidance. |

Custom CNC Machining Speaker Spikes Feet Shoes Prototyping Machining

Before producing custom CNC machining speaker spikes feet shoes, CNC prototyping is to verify the size and function. CNC prototyping avoids any potential issues before mass production, resulting in superior accuracy and precision. |

|

|

|

|

||

Custom CNC Machining Speaker Spikes Feet Shoes Surface Treatment |

Custom CNC Machining Speaker Spikes Feet Shoes Material |

||

|

The in-house material library allows customization of a wide range of metal and plastic materials, each with unique properties that affect the overall sound quality. We will choose the appropriate material according to the customer's product performance and appearance requirements. |

To ensure longevity and visual appeal, the custom CNC machining speaker spikes feet shoes feature a surface treatment. We can customize a variety of surface treatments, and have professional engineers for quality control. |

Custom CNC Machining Speaker Spikes Feet Shoes Parts Sample

|

|

|

||

|

|

|||

|

|

|

||

|

|

|||

|

|

|

| Materials play an important role in the performance of custom CNC machining speaker spikes. It has its own material library, which can provide material testing reports, and professional engineers can choose materials according to your requirements and performance. |

|

|

Stainless Steel CNC Speaker Spikes Feet Shoes

Stainless steel: Stainless steel is a popular choice for CNC machining speaker spike feet shoes due to its excellent vibration damping properties. It effectively absorbs vibrations and minimizes their transmission to the speaker cabinet, resulting in cleaner sound reproduction. Stainless steel feet shoes provide enhanced stability, reducing unwanted movements and maintaining speaker positioning.

More Details>> |

|

|

|

Aluminum CNC Speaker Spikes Feet Shoes

Aluminum: Aluminum is a common material for CNC machining speaker spikes. It achieves a balance of lightweight construction and durability, making it ideal for enhanced stability. Aluminum feet effectively isolate the speaker from the supporting surface, reducing resonance and unwanted vibration. Aluminum can be anodized in a variety of colors allowing for customization and visual appeal.

More Details>> |

|

|

|

Brass CNC Speaker Spikes Feet Shoes

Brass: Brass is a material known for its excellent resonance control capabilities. Customers use brass as a raw material because of the golden tone and aesthetics, but it is expensive.

More Details>> |

|

|

We can provide a variety of surface treatment options, with professional surface treatment team for quality control and improvement, the following are common surface treatments for custom CNC machined speaker spikes: |

|

1. Anodizing

Anodizing: Anodizing is a common surface finish used in custom CNC machining of speaker spikes. Multiple color options are also available, allowing customization and personalization of the footwear. |

|

|

2. Powder Coating

Powder coating: Powder coating provides excellent protection from corrosion, scratches and UV damage. It also offers multiple color options for custom speaker feet in multiple colors. The surface effect of anodizing and powder coating is similar, but the price is lower than anodizing. |

|

|

|

3. Electroplating

Electroplating: Electroplating is used to enhance the durability and aesthetics of speaker spikes. If you want a glossy surface effect, you can choose electroplating, and the highest mirror effect can be achieved. The cost is higher than anodizing. |

|

|

|

4. Surface Texturing

Surface Texturing: Surface Texturing is a surface treatment technology that improves the grip of the speaker spikes. By forming a textured pattern or grooves on the surface of the speaker spikes feet shoes, the ability of the speaker spikes feet to grip the supporting surface is enhanced and the risk of slipping is reduced. Surface textures can add a unique visual element and enhance the overall aesthetic of your speaker system. |

|

|

| Custom CNC machining enables engineered design and superior performance of a wide range of complex parts. The manufacturing process involves several key steps, from design and prototyping to final production of the footwear. |

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

1. Design and Prototyping

Design and Prototyping: The manufacturing process begins at the design stage. Design analysis can be carried out according to customer size, shape, and pattern requirements, and then CNC prototype processing can be carried out to ensure that the final product meets the specifications required by customers. |

|

Material selection: Once prototyping is complete, materials such as stainless steel, aluminum, brass, or high-density plastic are selected based on factors such as vibration dampening, stability, resonance control, and desired aesthetics. There are professional engineers to choose cost-effective materials for you. |

|

3. CNC Machining

CNC machining: CNC machining is the heart of the manufacturing process. With the design and material specifications in hand, CNC machines precisely carve and shape the raw materials into the desired speaker spike feet shoes. The process involves computer-controlled cutting, milling, drilling, and shaping to ensure accurate dimensions and fine details. |

|

Surface Treatments: After the CNC machining process, surface treatments are applied to the speaker spike feet shoes. These treatments serve two primary purposes: enhancing durability and improving aesthetics. Anodizing, powder coating, electroplating, or surface texturing techniques are utilized to protect the feet shoes from corrosion, wear, and tear, as well as to customize their appearance. |

|

5. Quality Control

Quality Control: Once the surface treatments are complete, the speaker spike feet shoes undergo rigorous quality control checks. This ensures that the final product meets the highest standards of quality and functionality. Any necessary finishing touches, such as deburring or polishing, are also performed to achieve a refined and visually appealing result. |

| Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

|

6. Packaging and Delivery

Packaging and Delivery: Packaging and transportation can be carried out according to customer requirements. If there is any problem, we will communicate with the customer to change the packaging requirements and transportation method to prevent any damage during transportation and ensure that they reach the customer in the best condition. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom CNC Machining Speaker Spikes Feet Shoes FAQs

|

Here are some frequently asked questions (FAQs) about custom CNC metal standoff screws home depot:

1. Can I order custom CNC metal standoff screws home depot in a non-standard size or shape?

2. What is the typical lead time for ordering custom CNC metal standoff screws home depot?

3. Can you assist in considering design considerations for custom CNC metal standoff screws home depot?

4. Can CNC metal standoff screws home depot customize those surface treatments?

5. How much is custom CNC metal standoff screws home depot?

We offer competitive prices for custom CNC machining speaker spikes feet shoes. Pricing depends on factors such as material, size, quantity, and additional requirements such as surface treatment. We strive to provide affordable solutions without compromising product quality and performance. According to your project needs, send an email to us for an immediate quotation for you.

These frequently asked questions should give you a better understanding of custom CNC machined speaker spikes and their applications. If you have any other questions or need more information, our professional engineering team is always ready to serve you, 24 hours online. |

Custom CNC Lathe Turning M3 M4 M5 astener Knurled Thumb Lead Free Brass Threaded Insert Nut

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.