15 years one-stop China custom CNC machining parts factory

Home / Product / Stainless Steel Parts /

Choose us as your stainless steel CNC machining manufacturer, you can rest assured. We use different processes combined with CNC machining to meet your needs. Available in a variety of stainless steel materials, strict quality control processes are carefully monitored at each step to ensure stainless steel CNC parts meet the highest industry standards for performance and durability.

Product Specification:

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

| Custom Steel Blackening CNC Machining Parts Precision Machining - OEM ODM CNC Milling Services Manufacturer - China VMT |

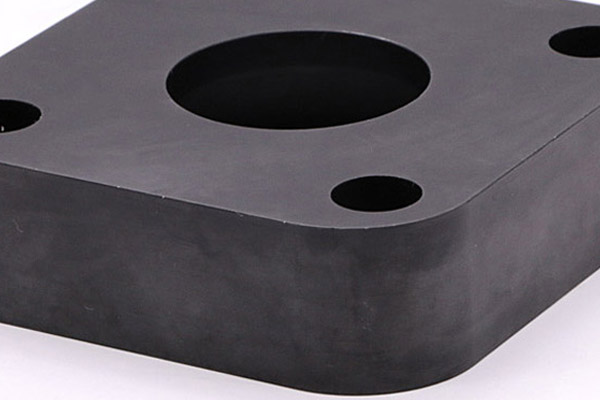

Custom Steel Blackening CNC Machining Parts Services

Custom Steel Blackening CNC Machining Parts Prototyping Machining

100 CNC machining equipment provide you with prototype manufacturing, evaluation, design and testing. We can complete CNC machining and delivery of stainless steel nickel plating CNC machining prototype parts according to your specific requirements within 1 day. |

|

|

|

|

||

Custom Steel Blackening CNC Machining Parts Surface Treatment |

Custom Steel Blackening CNC Machining Parts Material |

||

|

Our own material library can provide you with special materials such as stainless steel, brass, copper, aluminum, etc., with material testing reports attached. There are professional CNC stainless steel nickel plating CNC machining machining project engineers to choose the right materials for you. |

We can provide a variety of surface treatment services based on your Custom CNC stainless steel nickel plating CNC machining machining project: polishing, anodizing, powder coating, laser engraving, custom graphics, etc. 12 quality inspection processes ensure that your CNC machined parts have a yield rate of 98%. |

| Still selecting materials for your custom CNC machined metal stainless steel nickel plating CNC machining? Different materials have different properties, and you can customize the CNC stainless steel nickel plating CNC machining to your liking. Here are some common materials used in manufacturing metal stainless steel nickel plating CNC machining: |

|

|

|

||

12 Quality Inspection Processes

| Refined production standards, providing you with precision parts with a pass rate of up to 98% |

|

|

|

|

||

| DFM Analysis | Dimensional Tolerance | Material Testing | ||

|

|

|

|

||

| CNC Machining | FQC detection | SPC / CKP | ||

|

|

|

|

||

| Problem Found | Problem Solving | OQC Detection | ||

|

|

|

|

||

| Surface Treatment | Full Inspection | Package |

| The following is the manufacturing process of customized CNC machined metal stainless steel nickel plating CNC machining. Due to the need to protect the rights and interests of customers, the following picture is not the manufacturing process of this part and is for reference only: |

|

|

|

||

| DFM Analysis | Material | CNC Machining | ||

|

|

|

|

||

| Surface Treatment | Quality Inspection | Package |

|

Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

Custom Steel Blackening CNC Machining Parts Quality Assurance

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC machining work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom Steel Blackening CNC Machining Parts FAQs

|

1. What is blackening, and how is it applied to steel CNC-machined parts?

Blackening, also known as black oxide or bluing, is a chemical process that produces a black finish on steel parts. It forms an oxide layer on the surface, which enhances corrosion resistance and improves the appearance of the part. The process involves submerging the steel in a series of tanks containing alkaline and oxidizing chemicals, which chemically react with the metal to form the protective layer.

2. Why is blackening used on steel CNC-machined parts?

Blackening offers several advantages: Corrosion resistance: The black oxide layer helps protect the steel from rusting, especially when paired with a protective oil or sealant. Improved aesthetics: The black finish gives the part a sleek, uniform appearance, making it ideal for decorative or functional applications. Non-dimensional: Unlike plating or coatings, blackening does not add measurable thickness to the part, preserving the original dimensions and tolerances.

3. What are the benefits of blackening steel CNC parts over other surface treatments?

Cost-effective: Blackening is generally less expensive compared to plating or powder coating, especially for high-volume production. Retains dimensions: The process doesn’t significantly alter the part's dimensions, making it ideal for precision-machined parts where tight tolerances are required. Enhanced lubricity: Blackened surfaces are often smoother and more resistant to friction, making them ideal for moving parts or areas prone to wear. Conductivity: Unlike paint or powder coating, black oxide allows for electrical conductivity, which can be important in some applications.

4. What types of steel can undergo the blackening process?

Most carbon steels, alloy steels, and stainless steels can be blackened. Low carbon steels are the most commonly blackened materials, while stainless steel often undergoes a black oxide treatment with a different chemical process to achieve the same effect. Some high-alloy steels may require specific blackening formulations for optimal results.

5. How durable is blackening on steel CNC parts?

Blackening itself is relatively thin and can be prone to wear in highly abrasive environments. However, when sealed with oil or wax, the finish becomes much more durable, offering long-lasting protection against corrosion and wear. The black oxide finish is ideal for parts that are used in indoor or mildly corrosive environments, but may require additional coatings for extreme outdoor conditions.

6. What are the common applications for blackened steel CNC parts?

Automotive components: Blackened parts like gears, fasteners, and brackets are common due to the protective finish and improved appearance. Tools and hardware: Blackened finishes are often used for wrenches, pliers, screws, and other hardware items. Firearms: The process is frequently used on gun barrels and other firearm components for rust protection and improved appearance (often called bluing). Aerospace and defense: Black oxide-treated parts are often used in applications where non-reflective surfaces are necessary. Machinery and equipment: It’s used for components that require enhanced corrosion resistance and low reflectivity without altering part dimensions.

7. Does blackening add thickness or affect tolerances on CNC-machined parts?

No, blackening is a non-dimensional process. The oxide layer is extremely thin, typically only 1 to 3 microns (0.00004 to 0.0001 inches), which means it doesn’t affect the dimensions or tolerances of the part. This makes it an ideal treatment for precision-engineered components.

8. How does blackening compare to other corrosion protection methods like plating or powder coating?

Blackening: A non-dimensional process that retains tight tolerances and is best for moderate corrosion resistance when sealed with oil. It is cost-effective and provides a smooth, conductive surface. Plating: Adds a measurable layer of metal (e.g., zinc, nickel, or chrome) to enhance corrosion resistance and appearance. Plating can handle harsher environments but may affect part dimensions. Powder coating: A thicker, more durable coating that provides excellent corrosion resistance and is available in many colors, but it may not be suitable for precision parts that require conductivity or tight tolerances.

9. What post-blackening treatments can enhance the durability of blackened steel parts?

After blackening, parts are typically sealed with: Oil or wax: This penetrates the porous black oxide layer, providing additional corrosion protection and a richer, more uniform finish. Water-based sealants: Some applications may require a dry finish, where water-based sealants can be used to protect the surface without leaving an oily residue. These post-treatments are essential for maximizing the black oxide layer’s corrosion resistance and durability.

10. What information is required to request a quote for blackening steel CNC parts?

To get a quote for blackening, provide the following: Material specifications: Type of steel (carbon steel, stainless steel, etc.). Part dimensions: Include any tolerances that must be maintained. Quantity of parts to be treated. Desired finish: Specify any particular sealing methods (oil, wax, or dry finish) based on the intended application. Usage environment: Let the supplier know the conditions the parts will be exposed to (e.g., indoor vs. outdoor use) to ensure the proper treatment is applied. |

| We hope these CNC metal stainless steel nickel plating CNC machining faqs answer your questions. If you have more questions or require further assistance, please feel free to contact our dedicated customer support team. We're here to help you build the perfect custom CNC stainless steel nickel plating CNC machining just for you. |

Contact Us

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.