15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2022 02 02

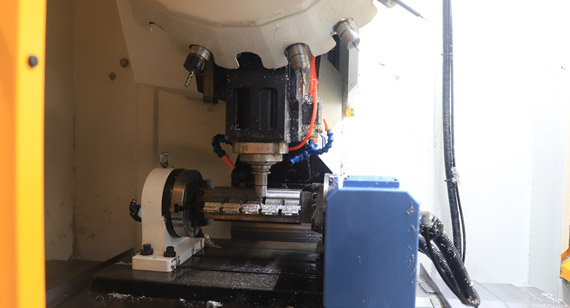

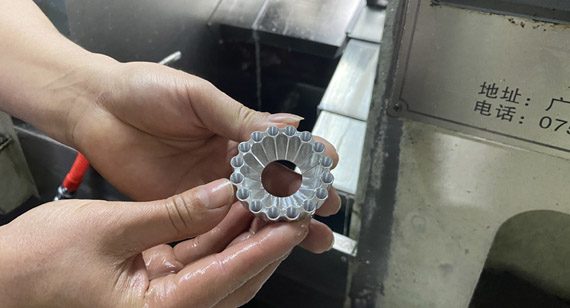

2022 02 02 There are various raw materials for CNC machining goods, among which CNC machining aluminum parts is one of the most processed. When applying CNC machining of aluminum parts, if you want to make the CNC machining model specifications more stable, you must pay attention to such areas.

66

66

Read more

Read more

VMT

VMT  2022 02 02

2022 02 02 In fact, most of the actual machining errors are caused by the unreasonable CNC machining technology. On the basis of ensuring the basic CNC machining technology, try to reduce the errors caused by iron filings to aluminum CNC machining parts.

66

66

Read more

Read more

VMT

VMT  2022 02 01

2022 02 01 Metal CNC machined stamping is a low-cost, fast manufacturing process that can produce large quantities of identical metal CNC machined parts. Metal transformations are carried out through various procedures.

66

66

Read more

Read more

VMT

VMT  2022 02 01

2022 02 01 As we all know, medical accessories have different requirements on the material and precision of products. Large medical equipment companies will also consider how to choose high-quality CNC machining suppliers, online collection, and many manufacturers seem to be similar. However, CNC machining companies with integrity and comprehensive strength are stretched thin.

66

66

Read more

Read more

VMT

VMT  2022 01 31

2022 01 31 With the continuous development of the CNC machining manufacturing industry, the production efficiency and quality of industrial products need to be improved urgently. The emergence of CNC machine tools has greatly improved the level of industrial production control.

66

66

Read more

Read more

VMT

VMT  2022 01 31

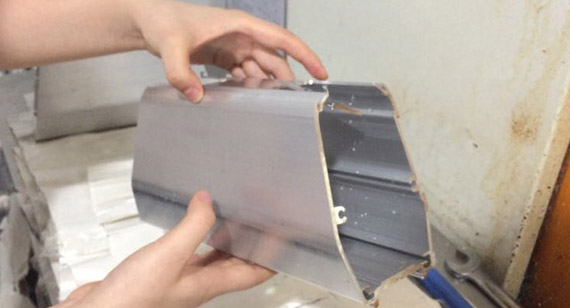

2022 01 31 Industrial aluminum alloy profiles are extremely versatile and widely used, and have the advantages of environmental protection, easy disassembly and assembly, saving time and money, etc. There are many kinds of industrial aluminum profiles with complete specifications, which are suitable for all kinds of machinery and equipment. No need for welding, convenient size adjustment, convenient structure adjustment.

66

66

Read more

Read more

VMT

VMT  2022 01 29

2022 01 29 The grinding of super-hard abrasive micro-powder grinding wheel can be carried out on CNC precision parts processing grinding machine. For precision grinding, it should be carried out on the corresponding CNC precision parts processing grinding machine.

66

66

Read more

Read more

VMT

VMT  2022 01 29

2022 01 29 In production, some parts are often plated locally, such as only the inner diameter surface; some are only plated on one end, while the rest are plated with other coatings; some are only plated on one side, while other parts are not allowed. Coated, etc. In order to achieve the purpose of local electroplating, the following methods can be used.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!