15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2022 04 22

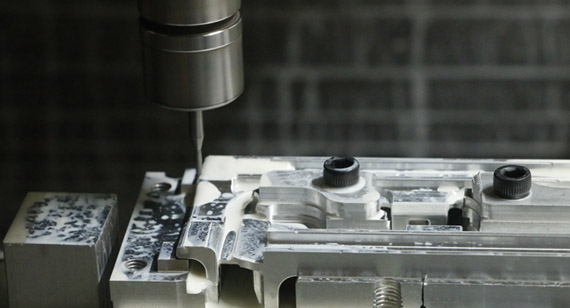

2022 04 22 In the production of batch CNC precision parts processing, because the workpiece requires high precision and short delivery time, the work efficiency of the equipment is the top priority of production and processing. Being able to grasp the simple basic knowledge can not only improve the production efficiency of CNC precision parts processing, but also reduce the failure rate of the equipment during use.

66

66

Read more

Read more

VMT

VMT  2022 04 21

2022 04 21 The larger the error, the lower the accuracy of the CNC machining center, the smaller the error, the higher the machining accuracy. The following is a brief introduction to the methods to improve the accuracy of CNC machining parts

66

66

Read more

Read more

VMT

VMT  2022 04 21

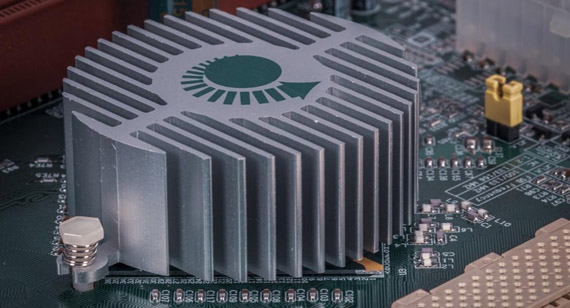

2022 04 21 CNC machining machines can process a wide variety of materials, whether conductive or non-conductive metals or plastics. Another advantage of using CNC machining is that it can produce the smallest semiconductors with extremely high precision. Any small or large CNC machined part of any geometric complexity can also be CNC machined.

66

66

Read more

Read more

VMT

VMT  2022 04 20

2022 04 20 They are many different types of CNC machining tools, from milling to turning and drilling, compatible with their respective CNC machining processes. All of these tools also have their general purpose and limitations. But CNC milling machines are the most used.

66

66

Read more

Read more

VMT

VMT  2022 04 20

2022 04 20 The creation of a finished product using humans, machines, tools, and biological or chemical processing is called the manufacturing process. Manufacturing can either mean converting raw materials into finished goods on a large scale, or producing more complex CNC-machined products by producing basic products for other manufacturers to produce CNC-machined parts for medical, electronics, automotive, and more.

66

66

Read more

Read more

VMT

VMT  2022 04 19

2022 04 19 Due to the wide variety of materials available, proper material selection is critical to the correct execution of CNC machining operations. The selected material must have all the necessary properties required by the customer. These properties may include strength, thermal stability, chemical resistance, hardness, stiffness, etc. Remember that budget plays an important role in choosing the right material.

66

66

Read more

Read more

VMT

VMT  2022 04 19

2022 04 19 There are many factors to consider when choosing between CNC machining and casting. There are also some similarities and differences between the two processes. Everything you need to know is discussed in detail below. Read on for more details.

66

66

Read more

Read more

VMT

VMT  2022 04 18

2022 04 18 The drawing that expresses the part is called the CNC machining part drawing. It is the basis for the manufacture and inspection of CNC machined parts, the basis for the production of process routes by the process department, and the basis for the inspection by the quality inspection department.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!