15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2022 01 28

2022 01 28 Magnesium alloys are metal alloys primarily composed of magnesium, along with various other elements such as aluminum, zinc, manganese, and rare earth metals. These alloys exhibit remarkable properties, including lightweightness, high strength-to-weight ratio, and excellent thermal conductivity. Magnesium alloys are commonly used in industries like aerospace, automotive, electronics, and medical.

66

66

Read more

Read more

VMT

VMT  2022 01 28

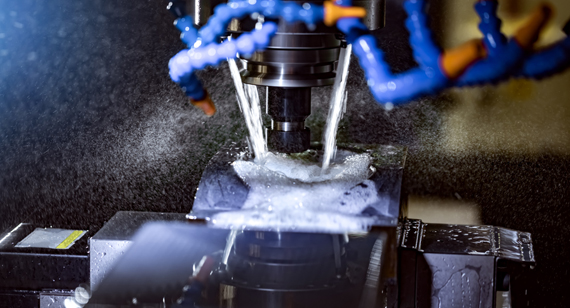

2022 01 28 Our state-of-the-art multi-axis CNC machining milling equipment allows us to deliver mechanical optics to meet your exacting requirements and to make your designs within tolerances of ±0.0005" or better.

66

66

Read more

Read more

VMT

VMT  2022 01 26

2022 01 26 Aluminum radiators are a common choice for most street and track performance applications. Performance-conscious customers choose to replace their radiators for a number of reasons: they want less weight, they are upgrading their cooling system to improve efficiency, or they want to improve the look of the underground.

66

66

Read more

Read more

VMT

VMT  2022 01 26

2022 01 26 Precision CNC machined parts almost determine the quality of the product. The more precise the hardware parts, the higher the precision requirements. So why does the precision of precision hardware parts deteriorate?

66

66

Read more

Read more

VMT

VMT  2022 01 25

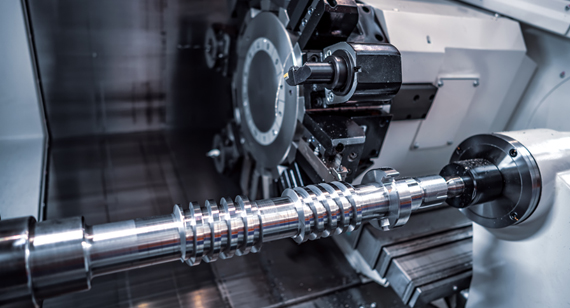

2022 01 25 With the development of internal thread CNC machining towards high performance, low cost and low energy consumption, the use of cold extrusion to form internal thread mesh has become an important part of anti-fatigue CNC machining. It has broad application prospects in aviation, aerospace, high-speed trains and other fields.

66

66

Read more

Read more

VMT

VMT  2022 01 25

2022 01 25 Turning and milling thin-walled parts (aluminum, aluminum alloys, pure titanium, copper, magnesium alloys) are prone to deformation during processing. The oval or "waist shape" has a small, medium and large end, which makes it difficult to guarantee the quality of the part.

66

66

Read more

Read more

VMT

VMT  2022 01 24

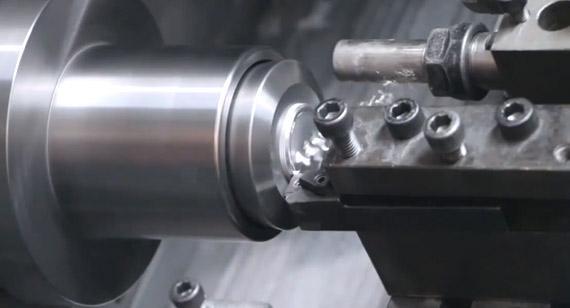

2022 01 24 Bearing CNC machining - Bearings, as an essential and important component in mining machinery products, play an important role in supporting the rotating shaft. According to the different friction properties in the bearing, the bearing is divided into rolling friction bearing (referred to as rolling bearing) and sliding friction bearing (referred to as sliding bearing).

66

66

Read more

Read more

VMT

VMT  2022 01 24

2022 01 24 In traditional CNC machining, three-axis machining centers and vertical machining centers are often used to complete the milling of workpieces.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!