15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2022 01 08

2022 01 08 VMT can provide customers with one-stop service for various aluminum alloy cnc processing and small batch customization. The scope of Wemet aluminum alloy CNC processing involves a variety of industries: automobiles, medical equipment, aviation equipment, communications, robots, etc.

66

66

Read more

Read more

VMT

VMT  2022 01 08

2022 01 08 It is because there are too many corporate customers who visit and negotiate aluminum precision cnc processing factories online. There are 3-4 customers every day, including customers from South Africa, Denmark, the United States, the United Kingdom, and Australia.

66

66

Read more

Read more

VMT

VMT  2022 01 07

2022 01 07 Hard cutting materials such as titanium alloys have been widely used in the aerospace industry due to their excellent high temperature performance. However, this kind of hard-cut material is difficult to be CNC machined.

66

66

Read more

Read more

VMT

VMT  2022 01 07

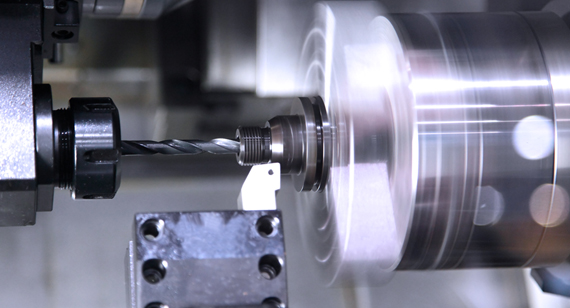

2022 01 07 In the CNC machining process, every process is very critical. If there is a careless and not timely operation in the CNC machining process, it is likely to immediately jeopardize the final actual effect of the product.

66

66

Read more

Read more

VMT

VMT  2022 01 06

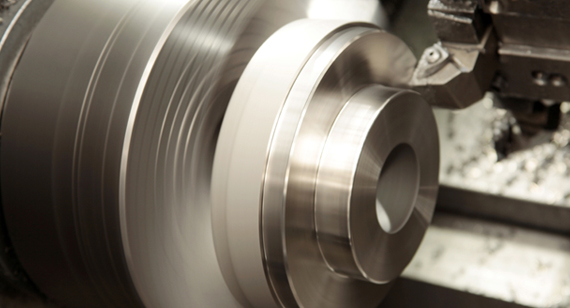

2022 01 06 Custom precision CNC machining parts are used in a wide range of applications and in a variety of types, such as automotive parts, electronic product decoration materials, and more. Now that the market economy has developed mature and promising products, they can all appear on the market in a relatively short period of time. Follow us to learn about it!

66

66

Read more

Read more

VMT

VMT  2022 01 06

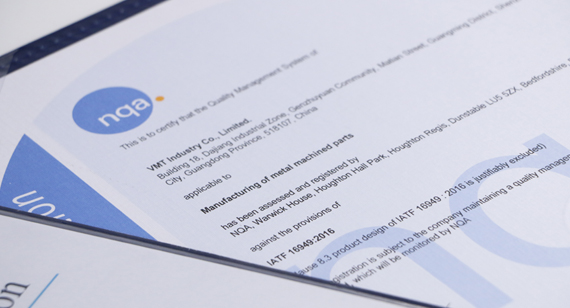

2022 01 06 VMT Information: Recently, Shenzhen VMT Metal Products Co., Ltd. ("VMT") has accepted the certification audit of Shanghai Enkeai (NQA) IATF 16949:2016 by an authoritative certification body. With the efforts of all the staff of the company, VMT officially obtained the IATF 16949: 2016 quality management system certificate.

66

66

Read more

Read more

VMT

VMT  2022 01 05

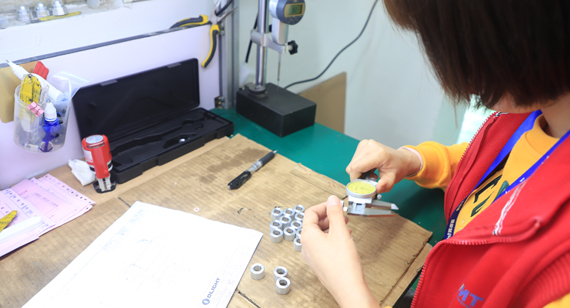

2022 01 05 IQC has returned the goods again, hurry up and arrange for personnel to come over for a full inspection, and the production line staff will stop there and wait! - Quality downtime costs

66

66

Read more

Read more

VMT

VMT  2022 01 05

2022 01 05 This material is just short of it. Why does the quality of CNC machined parts always have problems? Customers can't wait - the cost of credibility, the cost of inventory turnover.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!