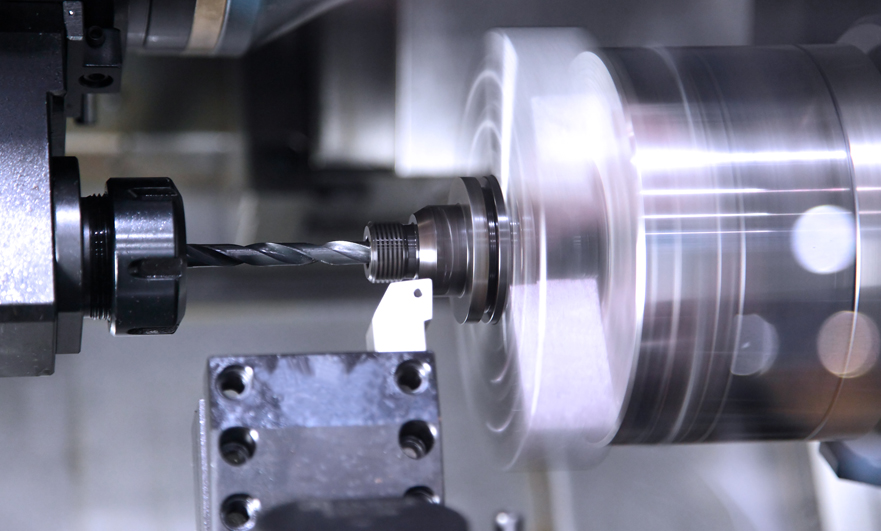

15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

119 |

Published by VMT at Jan 07 2022

119 |

Published by VMT at Jan 07 2022

In the CNC machining process, every process is very critical. If there is a careless and not timely operation in the CNC machining process, it is likely to immediately jeopardize the final actual effect of the product. Therefore, the operator must maintain a rounded mental outlook in the CNC machining project, which is not good for themselves, but also has a good impact on the product, so what will happen if the CNC machining technology is not properly configured?

The CNC machining process is too fragmented

The reason for this problem is the fear of complexity (referring to the preparation time), simple programming, simple operation and processing, easy to adjust the knife with the knife, and accustomed to ordinary CNC machining. This makes it difficult for product quality (position tolerance) to ensure CNC machining productivity.

Therefore, CNC machining technicians and operators should be fully familiar with CNC machining knowledge, try their best to master relevant knowledge, and try to use the method of centralized process for CNC machining. After using it several times, it will naturally reflect its advantages. After the processing is concentrated, the unit processing time increases. The two devices are arranged face to face, and one person operates two devices, which greatly improves the efficiency.

CNC machining sequence is unreasonable

Considering some problems in preparation, some CNC machining operators often arrange the processing sequence very unreasonably. CNC machining is usually carried out in accordance with the requirements of general machining process preparation, such as first roughing and then finishing (tool change), first inside and then outside, reasonable selection of cutting parameters, etc., so as to ensure the quality and efficiency of customized CNC machining parts.

Carefully use G00 (G26, G27, G29) fast positioning command G00 command brings great convenience to programming and use. However, if it is set and used improperly, it will often lead to overshoot when returning to zero, decrease in accuracy, and strain on the rail surface of the equipment due to the excessive speed setting. If the return-to-zero route is not careful, it is easy to cause a safety accident that collides with the workpiece and equipment. Therefore, when considering the use of G00 command, it should be carefully considered and not arbitrary.

In CNC machining, special attention should be paid to strengthening program retrieval and trial operation. After the program is entered into the control system, the operator should use the SCH key and the ↑, ↓, ←, → movement keys to search for uncertainty and certainty, and modify the program if necessary to ensure the accuracy of the program. At the same time, before the program CNC machining is officially executed, the program test run (turn on the power amplifier) must be carried out to confirm whether the CNC machining route is consistent with the design route.

Workpiece overcut:

reason:

1. Play the knife, the force of the knife should not be too long or too small. Make the knife bounce.

2. Improper operation by the operator.

3. The cutting allowance is uneven. (Example: leave 0.5 on one side of the surface and 0.15 on the bottom)

4. Improper cutting parameters (such as: tolerance is too large, SF setting is too fast, etc.)

promote:

1. The principle of using a knife: it can be large or small, short or long.

2. Add a corner cleaning program, keep the margin as uniform as possible (the margin and the bottom margin should be consistent).

3. Reasonably adjust the CNC machining cutting parameters, and the fillet allowance is large.

4. Using the SF function of the CNC machining machine, the operator can fine-tune the speed to achieve the best cutting effect.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!