15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2021 12 16

2021 12 16 CNC machining is increasingly used in today's CNC machining parts manufacturing plants. The reason behind the success of these CNC machining machines is obvious-they combine CNC milling and CNC turning, so that complex parts can be CNC machined in one operation, which greatly reduces the CNC machining time.

66

66

Read more

Read more

VMT

VMT  2021 12 15

2021 12 15 Special-shaped CNC machined parts are part of the flow temperature sensor. The CNC machined parts include curved surfaces, special-shaped grooves, special-shaped mounting seats, circumferentially distributed connecting studs and mounting holes, and high and low pressure interfaces.

66

66

Read more

Read more

VMT

VMT  2021 12 15

2021 12 15 Let us first understand the characteristics of CNC machining of aluminum and aluminum alloys: aluminum has low strength, low hardness, and high plasticity. It is suitable for plastic forming processing. However, it has a strong tendency to deform and strengthen during CNC machining, and it is easy to stick to the knife, and it is difficult to machine smoothly surface.

66

66

Read more

Read more

VMT

VMT  2021 12 14

2021 12 14 CNC machining is a manufacturing process that utilizes computer numerical control (CNC) systems to control machine tools. It enables precise and efficient production of complex parts and components. In CNC machines, the movement of the cutting tools is facilitated by rail systems, which guide the motion along a specific axis. Two common types of rail systems used in CNC machining are hard rail and linear rail.

66

66

Read more

Read more

VMT

VMT  2021 12 14

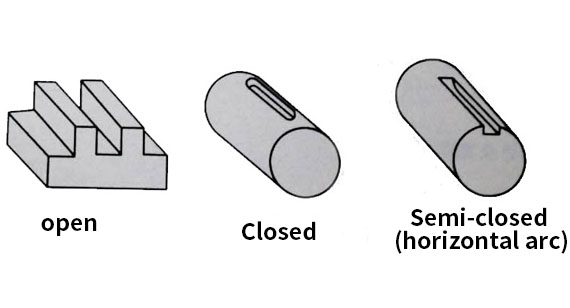

2021 12 14 Common right-angle grooves in precision CNC machining parts are open, closed and semi-closed. The end of the semi-closed groove has a vertical milling cutter arc (vertical arc) and a disc milling cutter arc ( Horizontal arc) two forms, the keyway on the shaft is a typical right-angle groove that connects the shaft and the sleeve with a flat key.

66

66

Read more

Read more

VMT

VMT  2021 12 13

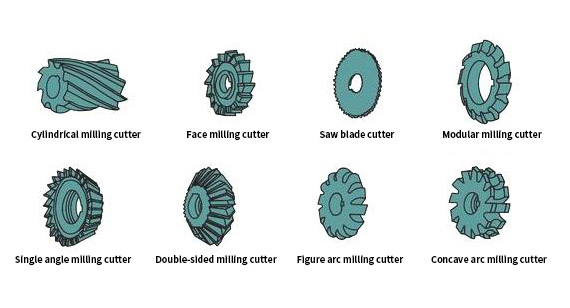

2021 12 13 To correctly determine and measure the geometric angle of the milling cutter, two coordinate planes of the angle measurement datum are required, namely the base plane and the cutting plane.

66

66

Read more

Read more

VMT

VMT  2021 12 13

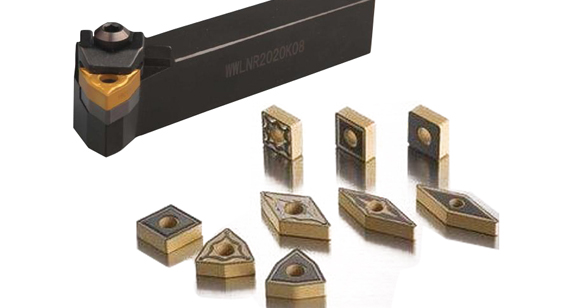

2021 12 13 As we all know, cemented carbide is an alloy material formed by combining refractory metal and metal through powder metallurgy. An alloy composed of one or more carbides and a cemented metal drill bit is often called a cemented carbide.

66

66

Read more

Read more

VMT

VMT  2021 12 11

2021 12 11 As the basis of modern mechanical manufacturing technology, CNC machining technology has undergone major changes in the manufacturing process of CNC machining parts. Compared with traditional numerical control processing technology, modern numerical control processing technology has obvious differences in processing process, process control, processing equipment, processing equipment and so on.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!