15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

121 |

Published by VMT at Dec 15 2021

121 |

Published by VMT at Dec 15 2021

1. Description of the structural characteristics of special-shaped CNC machining parts

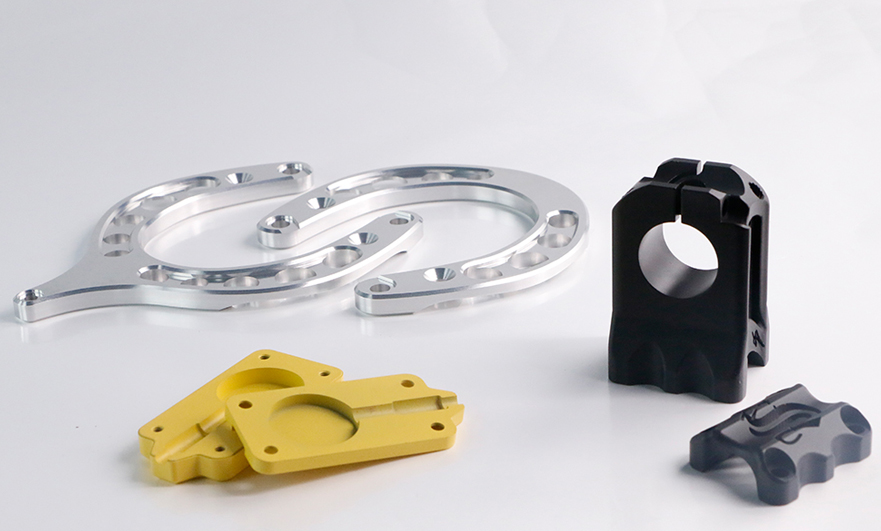

Special-shaped CNC machined parts are part of the flow temperature sensor. The CNC machined parts include curved surfaces, special-shaped grooves, special-shaped mounting seats, circumferentially distributed connecting studs and mounting holes, and high and low pressure interfaces. The structural characteristics are shown in the figure below.

①High and low pressure pipe interface

There are high and low pressure pipe interfaces distributed on the contour surface of the special-shaped CNC machining parts. As the airflow enters from the equal-diameter inlet section, it passes through the shrinkage of the aperture and the transition of the roaring stage. The greater the gas passing through the roaring channel, the greater the gas flow pressure. small. On the contrary, after the expansion of the aperture becomes larger and the roaring stage transitions, the lower the speed of the gas passing through the roaring channel, the greater the gas flow pressure generated.

②Fixed installation pillar

The high-pressure zone and the low-pressure zone each have a fixed installation pillar, with the same structural size, and the central position of the safety hole is CNC processed, which plays the role of fixing and matching parts.

③Interface of temperature sensing component

The size of the interface is connected with the temperature-sensing component, and the inner hole is threaded numerically processed. The height of the pillar and the thread depth are related to the structure of the temperature-sensing component, and there is a safety hole at the 45° position behind the interface of the temperature-sensing component. Play the role of fixing cooperating parts. VMT is a CNC machining factory with 11 years of CNC machining experience, with more than 160 CNC machining equipment and testing instruments, CNC turning / milling / grinding /drilling / machining, welcome emails and calls from partners who have CNC machining parts requirements Contact for a quote.

④Sealed interface

The sealing interface is divided into an inlet end and an outlet end, and both are connected with the sealing ring. The CNC machining requires high dimensional accuracy to ensure that there is no leakage of the gas flow at the inlet and outlet ends, otherwise it will cause a loss of pressure on the gas flow and pressure in the inner cavity , Resulting in inaccurate airflow pressure at the output end of the high and low pressure pipe interface.

⑤Upper and lower cover installation groove

U-shaped grooves are evenly distributed on the inside of the platform on the front and back of the special-shaped CNC machining parts, and the local positions are connected with the welding pillars. They are fixed by the welding CNC machining process. After forming, screw the upper and lower cover plates to the CNC machining parts, and close the CNC connected with the venturi tube Machining parts and other test products.

2. Difficulty analysis of CNC machining and programming creation

Aiming at the pillar interface features of the contour and surface distribution of the special-shaped CNC machining parts, the four-axis CNC machining programming method is adopted, and the CATIA-CAM CNC machining programming software is used to prepare the pre-processing program.

The clamping method of four-axis CNC machining parts adopts mandrel positioning, the mandrel is clamped on the rotating worktable, and the A-axis rotation drives the CNC machining parts to be linked with the spindle during the process. The positioning datum of the mandrel refers to the central axis of rotation of the CNC machined parts. According to the inner cavity structure and dimensional tolerance requirements of the special-shaped CNC machined parts, it is determined that the mandrel working surface and the inner wall of the special-shaped CNC machined parts fit well.

Keep the circle runout ≤ 0.01, coaxiality ≤ 0.02. In terms of function, the mandrel provides torque through static friction to ensure the stability of cutting CNC machining; the mandrel provides radial support to prevent the cutting force from deforming the thin-walled parts of the special-shaped CNC machined parts. At the same time, the roughness of the working surface of the mandrel should be above Ra0.8, and the surface will be smoothly transitioned, and it will not scratch the inner wall of the special-shaped CNC machined parts.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!