15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2021 11 13

2021 11 13 I believe everyone has a basic understanding of 5-axis CNC machining, which is more flexible and more precise than three-axis CNC machining. The 5-axis CNC machining method is more flexible and has a good performance in the processing of curved surfaces.

66

66

Read more

Read more

VMT

VMT  2021 11 10

2021 11 10 Precision CNC machining services are the ideal choice for customers who need to process and manufacture, covering a wide range of industries and professional applications. VMT CNC parts machining service company can process stainless steel, carbon steel, brass, aluminum, titanium, bronze, plastic and other parts.

66

66

Read more

Read more

VMT

VMT  2021 11 08

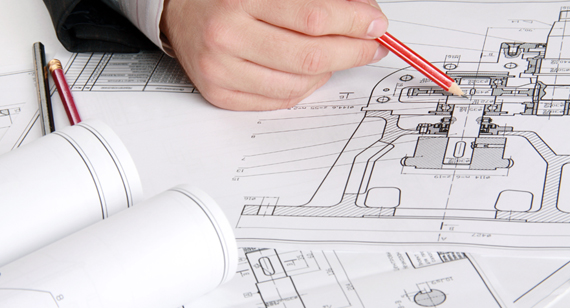

2021 11 08 VMT works with customers during the design process to help achieve optimal functionality and aesthetics while reducing costs. Planning the machining method, while at the forefront of manufacturing design and assembly design for CNC machining parts.

66

66

Read more

Read more

VMT

VMT  2021 11 08

2021 11 08 The customer found us through the Google website. We successfully gained the trust and affirmation of our customers with our strong professional technology, rich CNC machining experience, equipment and competitive price. Responsible for the CNC machining of stainless steel parts for advertising nails on glass discs. Because of the use on glass, many factors are considered, so we have made a series of efforts.

66

66

Read more

Read more

VMT

VMT  2021 10 30

2021 10 30 2D drawing machining and manufacturing is still widely used in CNC machining services. This is because most of them are NC machined parts graphics generated by three-dimensional models and numbers that have not been updated.

66

66

Read more

Read more

VMT

VMT  2021 10 30

2021 10 30 The maximum size of CNC machining is mainly related to the maximum machining size of the machine tool, that is, the maximum moving distance of the pallet. It is also related to the size of the system limit. The system limit is determined according to the value of the coordinate system.

66

66

Read more

Read more

VMT

VMT  2021 10 30

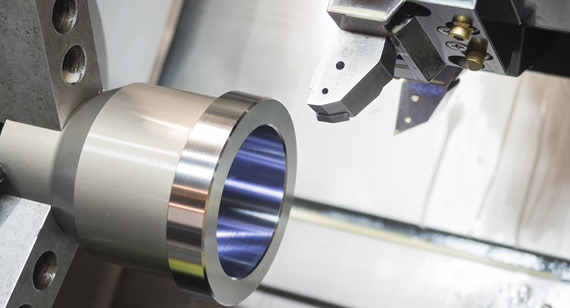

2021 10 30 Swiss CNC turning and traditional CNC turning are two different methods used to process metal or other raw material parts. Specifically, machining is the process of taking material from a workpiece and shaping it into a predetermined design.

66

66

Read more

Read more

VMT

VMT  2021 10 29

2021 10 29 Simply put, the main difference between iron and non-ferrous metals is the presence of iron. Ferrous metals contain iron, while non-ferrous metals do not contain iron. In a narrow sense, non-ferrous metals are also called non-ferrous metals, which are collectively called all metals except iron, manganese, and chromium.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!