15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2021 10 23

2021 10 23 It is generally believed that the cutting speed and feed speed are 5~10 times higher than the traditional processing method called CNC milling machine high-speed cutting (processing).

66

66

Read more

Read more

VMT

VMT  2021 10 22

2021 10 22 When CNC machined parts need to protect the appearance and durability of materials, surface treatment is usually made on CNC machined parts. When CNC machined parts need to protect the appearance and durability of materials, surface treatment is usually made on CNC machined parts. However, the surface treatment of the parts has complicated processes. If you need s

66

66

Read more

Read more

VMT

VMT  2021 10 22

2021 10 22 Electroplating is a common surface treatment. It uses electrolysis to attach a metal film to the surface of a metal or other material to prevent metal oxidation (such as rust) and improve aesthetics. Among them, it can be divided into rack plating, barrel plating, continuous plating, brush plating and other process methods, which are mainly related to the size and batch of parts to be plated.

66

66

Read more

Read more

VMT

VMT  2021 10 22

2021 10 22 On-Demand Manufacturing is a manufacturing system that provides online product machining custom. It is a platform for realizing small batch product machining custom under intelligent manufacturing and providing online CNC machining parts.

66

66

Read more

Read more

VMT

VMT  2021 10 21

2021 10 21 Overheating and overcooling of temperature will have certain influences: "causing uneven temperature rise in various parts of the machine tool", "workpiece deformation", "influencing accuracy" and other issues. This article mainly describes how the temperature in winter affects CNC machining performance. Explore it!

66

66

Read more

Read more

VMT

VMT  2021 10 21

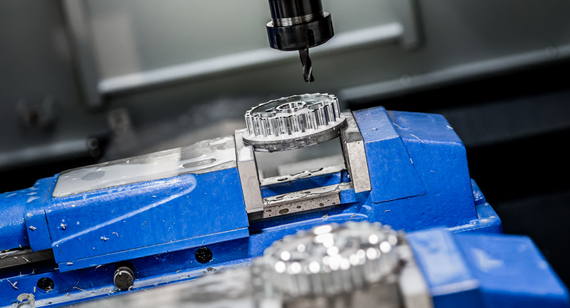

2021 10 21 Gear is one of the indispensable parts of mechanical manufacturing. The main function of the wheel is to transmit power. Different gear combinations can play different roles. Acceleration, deceleration, and direction change are all possible. This article mainly talks about the relevant knowledge about gears.

66

66

Read more

Read more

VMT

VMT  2021 10 21

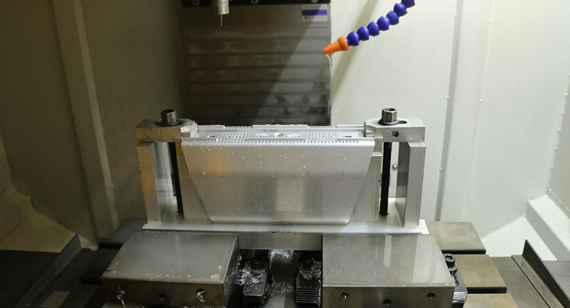

2021 10 21 In recent years, the standard of CNC custom machining of cases has been continuously improved. Therefore, manufacturers of CNC custom machining have also improved their innovative technology and accuracy to varying degrees in order to maintain their competitiveness.

66

66

Read more

Read more

VMT

VMT  2021 10 20

2021 10 20 VMT is a manufacturer of CNC auto parts prototypes and on-demand production machining parts. Get real-time quotes about CNC auto parts machining services, CNC turning milling services, 5-axis CNC machining services, etc. Hundreds of materials and Surface Finishing services ensure the quality of parts so that your parts can be used in the first time.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!