15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

157 |

Published by VMT at Oct 20 2021

157 |

Published by VMT at Oct 20 2021

In the next round of manufacturing revolution, 3D printing, robotics and other technologies will change the way factories produce and process manufacturing, and companies will also reconsider their products and production bases. Small-volume, highly personalized products will be assembled on the assembly line. The sophisticated products are like high-tech traditional handicrafts. Although technology makes this new manufacturing model possible, the driving force for the implementation of this model comes from customers.

In emerging markets and developed regions, customers increasingly hope that products can cater to local cultural preferences, rather than homogeneous global brands and B2B services. As early as the 1980s, the automotive industry became the leader of the localization model. Benefiting from the on-demand manufacturing model, flexible machining and manufacturing companies will make a lot of money. As the responsiveness of the supply system continues to improve, local customer needs become clearer, the efficiency of inventory management has improved, and the transportation cost of large quantities of products will also be reduced.

Advantages of on-demand production and manufacturing in the automotive industry

1. Flexible design scheme

For dealers, on the one hand, they face pressure on the inventory, on the other hand they have to compete for best-selling models. For most multinational car companies, the speed of change in the Chinese market is often unexpected, and the demand in different regions is not the same. This requires high-frequency adjustments to the production plan, otherwise it will lead to squeezing of warehouses and unsalable models. Modularization of the production process means that the assembly line is divided into several relatively independent modules.

Each module has flexible time and can be flexibly adjusted according to the model and quantity of the product, thereby minimizing the interference to other process modules and the entire production process. , So that production can be carried out more smoothly and efficiently. The factory will have a powerful database that enables designers to review previous adjustments, improve future components, and monitor changes to completed prototypes. On-demand manufacturing is very valuable for the automotive industry seeking rapid transformation of.

2. No minimum order quantity

No matter how many samples you need, even if you only need one sample, the on-demand production and processing manufacturer can quickly meet your order requirements. As the pace of design progresses and needs change, we have many methods, such as rapid mold and vacuum casting, and can provide services such as small batch production for you to choose from.

3. Fast turnaround

Earlier this year, the National Development and Reform Commission stated that in 2015, the passenger vehicle capacity utilization rate of 37 major automobile companies (groups) was 81%, and the capacity utilization rate was relatively reasonable. The commercial vehicle capacity utilization rate was 52%, and the capacity utilization rate was 52%. Insufficient, the problem of structural surplus of automobile production capacity has emerged.

But even in the field of passenger cars, there have been constant confrontations between dealers and manufacturers in recent years, and the reason behind it is nothing more than pressure on inventory and high sales targets. The delivery cycle is time-consuming. These confirmed minimum order quantities waste a lot of time for customers to take on unnecessary parts. On-demand production and processing are based entirely on customer needs, which greatly shortens the waiting time for customers, and even quick turnaround of 3-7 days, which speeds up the launch of customer products.

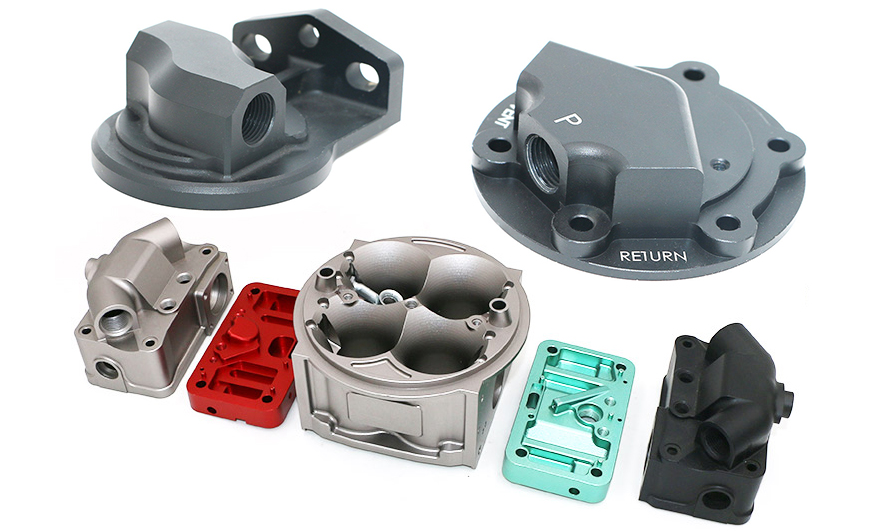

VMT is a CNC auto parts prototypes and on-demand production machining parts manufacturer . Get real-time quotes on CNC auto parts machining, CNC machining services, CNC turning and milling machining services, 5-axis CNC machining services, etc. Hundreds of materials and Surface Finishing services ensure the quality of parts so that your parts can be used in the first time.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!