15 years one-stop China custom CNC machining parts factory

132 |

Published by VMT at Sep 08 2025 | Reading Time:About 4 minutes

132 |

Published by VMT at Sep 08 2025 | Reading Time:About 4 minutes

Choosing the right stainless steel is challenging. Many engineers and buyers struggle to decide between 420 stainless steel and 316 stainless steel. The wrong choice can lead to unexpected corrosion, higher costs, or machining difficulties. Fortunately, by understanding their differences in composition, properties, and performance, you can make the right choice for your CNC machining project.

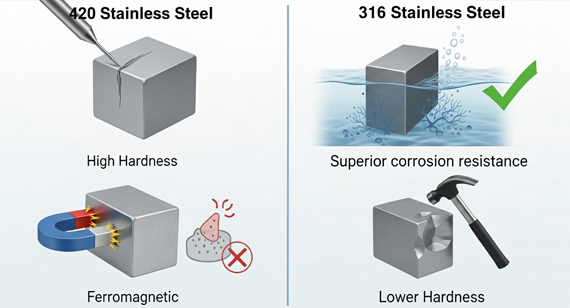

420 stainless steel is a hardenable martensitic steel known for high wear resistance, while 316 stainless steel is an austenitic grade with excellent corrosion resistance. Choose 420 for cutting tools and wear parts; select 316 for marine, chemical, or medical applications.

Now that you know the core difference, let’s dive deeper into the composition, properties, and machining performance of 420 stainless steel vs. 316 stainless steel to help you choose wisely.

420 stainless steel (SS420) is a martensitic stainless steel with high carbon content. It can be heat-treated to achieve good hardness (up to 50 HRC), making it ideal for cutting tools, surgical instruments, and wear-resistant parts. However, compared with austenitic grades, its corrosion resistance is lower, especially in harsh or marine environments.

For CNC machining, 420 stainless steel CNC machined parts are preferred when hardness, wear resistance, and polishability are more important than corrosion resistance. Common applications include knives, molds, pump shafts, and certain aerospace components.

316 stainless steel (SS316) is an austenitic stainless steel containing molybdenum (2–3%), which gives it excellent corrosion resistance, especially against chlorides and chemicals. It is widely used in marine, chemical, food processing, and medical industries where resistance to rust, pitting, and high temperatures is critical.

For CNC machining, 316 stainless steel CNC machined parts are popular due to their strength, durability, and resistance to harsh environments. While softer than martensitic grades like 420, it is easier to weld and maintain stability under extreme conditions.

When comparing 420 stainless steel and 316 stainless steel, it’s essential to understand their differences in composition, properties, and performance. These factors determine their suitability for various industries, from cutting tools and molds to marine equipment and medical implants. Below, we’ll look at each property to help you choose the right material.

Composition

Note: For CNC machining factories, composition directly impacts machinability and performance — selecting the wrong steel grade may increase tool wear and project costs.

Hardness

Tip: Choose 420 if you need sharp edges or high wear parts. For structural durability and weldability, 316 is superior.

Corrosion Resistance

Tip: For marine and medical CNC machined parts, 316 stainless steel is the safe choice. Avoid 420 unless corrosion is not a critical factor.

Wear Resistance

Note: Using 316 in high-wear conditions may increase part replacement costs over time.

Oxidation Resistance

Welding

Tip: If your CNC project requires welded assemblies, 316 stainless steel is the better option.

Heat Resistance

Machinability

Tip: To reduce machining costs, consider annealed 420 stainless steel for high-hardness projects, but prepare for higher tool wear when machining hardened material.

Cost

Applications

Tip: When outsourcing CNC machining services, clearly define the working environment of your part to avoid material mismatches that increase overall costs.

420 Stainless Steel vs. 316 Stainless Steel: Key Differences

| Property |

420 Stainless Steel (SS420) |

316 Stainless Steel (SS316) |

| Type |

Martensitic stainless steel | Austenitic stainless steel |

| Composition |

High carbon (0.15–0.4%), 12–14% Cr | 16–18% Cr, 10–14% Ni, 2–3% Mo |

| Hardness (HRC) |

Up to 50 HRC (heat-treated) | 15–20 HRC (softer) |

| Corrosion Resistance |

Moderate, prone to rust in salty/acidic environments | Excellent, resists seawater and chemicals |

| Wear Resistance |

Very high, suitable for cutting tools and molds | Lower, not ideal for friction-heavy use |

| Oxidation Resistance |

Up to 650 °C | Up to 870 °C |

| Welding |

Difficult, needs pre/post-heat treatment | Excellent weldability |

| Heat Resistance |

Moderate, loses resistance above 400 °C | Excellent, maintains resistance up to 870 °C |

| Machinability |

Good when annealed, harder when heat-treated | Tough to machine, work-hardens easily |

| Cost |

Lower initial cost | Higher upfront cost |

| Applications |

Knives, surgical tools, molds, pump shafts | Marine equipment, chemical tanks, medical implants |

420 Stainless Steel (SS420)

Advantages:

Disadvantages:

Tip: Use 420 stainless steel for applications where hardness and wear resistance are more important than corrosion resistance, such as knives, molds, and pump shafts.

316 Stainless Steel (SS316)

Advantages:

Disadvantages:

Tip: Choose 316 stainless steel for CNC machined parts used in marine, food, chemical, or medical industries — it offsets higher upfront costs with long-term savings.

The performance of 420 stainless steel (SS420) and 316 stainless steel (SS316) comes down to their chemical composition. Elements like carbon, chromium, nickel, and molybdenum define hardness, corrosion resistance, weldability, and machinability. Understanding these differences helps engineers and CNC machining factories select the best material for specific applications.

420 Stainless Steel vs. 316 Stainless Steel: Chemical Composition

| Element |

420 Stainless Steel (SS420) |

316 Stainless Steel (SS316) |

| Carbon (C) |

0.15 – 0.40% | ≤ 0.08% |

| Chromium (Cr) |

12 – 14% | 16 – 18% |

| Iron (Fe) |

Balance | Balance |

|

Manganese (Mn) |

≤ 1.0% | ≤ 2.0% |

| Molybdenum (Mo) |

— | 2.0 – 3.0% |

| Nickel (Ni) |

≤ 0.75% | 10 – 14% |

| Nitrogen (N) |

— | ≤ 0.10% |

| Phosphorus (P) |

≤ 0.04% | ≤ 0.045% |

| Silicon (Si) |

≤ 1.0% | ≤ 1.0% |

|

Sulfur (S) |

≤ 0.03% | ≤ 0.03% |

420 Stainless Steel vs. 316 Stainless Steel: Physical Properties

Physical properties such as density, melting point, conductivity, corrosion resistance, and machinability directly affect how stainless steel performs in real-world applications. Comparing 420 stainless steel (SS420) and 316 stainless steel (SS316) helps engineers and CNC machining factories match the right material to the working environment and processing requirements.

Property Comparison Table

| Property | 420 Stainless Steel (SS420) | 316 Stainless Steel (SS316) |

| Density (g/cm³) | 7.75 | 7.98 |

| Melting Point (°C) | 1,480 – 1,530 | 1,370 – 1,400 |

| Thermal Conductivity (W/m·K) | ~24 | ~16 |

| Electrical Resistivity (Ω·m) | 5.5 × 10⁻⁷ | 7.4 × 10⁻⁷ |

| Thermal Expansion (10⁻⁶/K) | 10.0 – 10.4 | 16.0 – 16.5 |

| Corrosion Resistance | Moderate, prone to rust in saline/acidic media | Excellent, resists seawater and chemicals |

| Magnetic Properties | Magnetic (martensitic) | Non-magnetic (austenitic, may be slightly magnetic after cold work) |

| Formability | Poor–moderate, limited shaping ability | Excellent, easily formed into complex shapes |

| Machinability (annealed state) | Good | Fair (work-hardens, requires sharp tools) |

| Environmental Adaptability | Performs well in dry, wear-intensive environments | Performs best in humid, corrosive, marine, or chemical conditions |

420 Stainless Steel and 316 Stainless Steel: Mechanical Properties

The mechanical properties of stainless steels define their performance under stress, wear, and fatigue. 420 stainless steel (SS420) stands out for hardness and wear resistance, while 316 stainless steel (SS316) is valued for toughness, ductility, and corrosion resistance. Comparing these properties helps determine which grade fits best for CNC machined parts in demanding industries.

Mechanical Property Comparison

| Property |

420 Stainless Steel (SS420) |

316 Stainless Steel (SS316) |

| Hardness (HRC) |

Up to 50 (heat-treated) | ~15–20 |

| Hardness (HV) |

~500 | ~150–200 |

| Hardness (HRB/HRC) |

HRB 95 (annealed), HRC 50 (hardened) | HRB 80–95 |

| Tensile Strength (MPa) |

700–1,400 (heat treatment dependent) | 515–620 |

| Yield Strength (Rp0.2, MPa) |

~600 | ~205 |

| Elongation at Break (%) |

10–15 | 40–50 |

| Ductility (%) |

Low–moderate | High |

| Ultimate Tensile Strength (MPa) |

~1,000 | ~580 |

| Reduction of Area (Z, %) |

~40 | ~60–70 |

| Heating Temperature (°C) |

Up to 650 (limited) | Up to 870 (sustained) |

| Elastic Modulus (GPa) |

200–210 | 193 |

| Fatigue Strength (MPa) |

~275 | ~240 |

| Shear Strength (MPa) |

~550 | ~290 |

| Shear Modulus (GPa) |

~80 | ~77 |

| Poisson’s Ratio |

0.27–0.30 | 0.28–0.31 |

| Area Reduction (%) |

35–45 | 55–70 |

420 Stainless Steel (SS420)

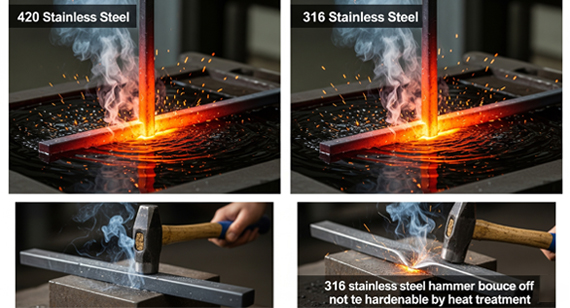

420 stainless steel is heat-treatable, which is one of its key advantages. The process typically involves:

This flexibility makes 420 ideal for cutting tools, knives, and wear-resistant CNC machined parts.

316 Stainless Steel (SS316)

Unlike 420, 316 stainless steel is not hardenable by heat treatment. Its strength and toughness come from its austenitic structure. Instead, it can be strengthened by:

This makes 316 best suited for corrosive and high-temperature environments rather than cutting or wear applications.

420 Stainless Steel vs. 316 Stainless Steel: Heat Treatment

| Property / Process |

420 Stainless Steel (Martensitic) |

316 Stainless Steel (Austenitic) |

| Heat Treatable |

✔ Yes – can be hardened and tempered | ✘ No – cannot be hardened by heat treatment |

| Annealing |

840–900 °C, furnace cool slowly | 1,040–1,120 °C, rapid water quench |

| Hardening |

980–1,040 °C, oil or air quench | Not applicable |

| Tempering |

150–370 °C (balance hardness & toughness) | Not applicable |

| Achievable Hardness |

Up to ~50 HRC after hardening | ~HV 150–190 (non-hardenable) |

| Strengthening Method |

Heat treatment (hardening + tempering) | Cold working (strain hardening) |

| Main Purpose of Treatment |

Wear resistance, cutting performance | Restore ductility & corrosion resistance |

| Industrial Use |

Knives, surgical tools, wear-resistant CNC machined parts | Chemical, marine, food, and medical components |

| Category |

420 Stainless Steel (Martensitic) |

316 Stainless Steel (Austenitic) |

| Cutlery & Knives |

Kitchen knives, surgical scalpels, scissors, razor blades (requires sharp edge + hardness) | Rarely used – too soft for blades |

| Medical Instruments |

Surgical tools, dental instruments (hard, wear-resistant, sterilizable) | Surgical implants, medical devices (biocompatibility + corrosion resistance) |

| Industrial Components |

Pump shafts, valve parts, bearings (where hardness matters) | Chemical tanks, heat exchangers, piping systems (resists acids, chlorides) |

| Aerospace & Automotive |

Turbine blades, wear-resistant parts, molds | Exhaust systems, structural parts in corrosive environments |

| Marine Applications |

Limited – corrodes in seawater | Widely used – resists seawater and salt spray (boats, marine fasteners) |

| Consumer Products |

Scissors, tools, machine parts | Cookware, food processing equipment, appliances |

| CNC Machined Parts |

Wear-resistant, high-hardness parts | Corrosion-resistant, high-toughness parts |

Key Insight:

Cost is a critical factor when selecting stainless steel for CNC machined parts. While 420 stainless steel (SS420) typically has a lower upfront price, 316 stainless steel (SS316) can reduce long-term maintenance costs due to its superior corrosion resistance. Understanding both initial and ongoing costs helps optimize project budgets.

Cost Comparison Table

| Cost Aspect |

420 Stainless Steel (SS420) |

316 Stainless Steel (SS316) |

| Initial Material Cost |

Lower – generally more affordable | Higher – due to nickel and molybdenum content |

| Long-Term Cost Benefits |

Higher maintenance needed in corrosive environments | Lower maintenance; longer service life in harsh conditions |

| Processing / Machining Costs |

Moderate; easier to machine in annealed state | Higher; work-hardening requires sharp tools and slower machining |

| Market Price (per kg / ton) |

~$3–5/kg (depends on supplier & condition) | ~$5–8/kg (depends on supplier & market) |

Stainless steel grades are standardized internationally to ensure consistent performance in CNC machining and manufacturing. Knowing the national standards and equivalent grades of 420 and 316 stainless steel helps engineers source the correct material for specific applications and verify compatibility across suppliers.

420 Stainless Steel Standards and Equivalents

| Standard Body |

Equivalent Grade |

| AISI / ASTM |

420 |

| EN (Europe) |

X46Cr13 |

| JIS (Japan) |

SUS420J2 |

| DIN (Germany) |

1.4021 |

| GB (China) |

420 |

316 Stainless Steel Standards and Equivalents

| Standard Body | Equivalent Grade |

| AISI / ASTM | 316 |

| EN (Europe) | X5CrNiMo17-12-2 |

| JIS (Japan) | SUS316 |

| DIN (Germany) | 1.4401 |

| GB (China) | 06Cr17Ni12Mo2 |

Selecting between 420 stainless steel (SS420) and 316 stainless steel (SS316) depends on the application environment, mechanical demands, and cost considerations. Understanding their strengths and weaknesses ensures you pick the right material for your CNC machined parts, reducing failures, maintenance, and overall project costs.

When Should You Use 420 Stainless Steel?

Tip: Avoid using 420 stainless steel in marine, chemical, or highly humid environments — it will corrode faster without protective coatings.

When Should You Use 316 Stainless Steel?

Tip: While 316 stainless steel has a higher upfront cost, it often lowers long-term expenses due to superior corrosion resistance and extended service life.

How to Choose Between 420 and 316 Stainless Steel

| Criteria / Factor |

420 Stainless Steel (SS420) |

316 Stainless Steel (SS316) |

| Primary Advantage |

High hardness and wear resistance | Excellent corrosion resistance and toughness |

| Best Environment |

Dry or low-corrosion environments | Marine, chemical, food, and medical environments |

| Ideal Applications |

Knives, cutting tools, molds, bearings | Chemical tanks, marine components, medical devices |

| Cost Consideration |

Lower initial cost | Higher initial cost, but lower long-term maintenance |

| Machinability |

Good in annealed condition; harder after heat treatment | Fair; work-hardens easily, requires sharp tools |

| Welding / Fabrication |

Difficult; pre/post-heat treatment required | Excellent weldability and formability |

| Maintenance & Longevity |

Higher maintenance in corrosive environments | Longer service life; low maintenance required |

Choosing between 420 stainless steel (SS420) and 316 stainless steel (SS316) depends on your project’s functional requirements and environmental conditions. Both grades have distinct advantages that make them suitable for different CNC machined parts.

Choose 420 Stainless Steel if:

Choose 316 Stainless Steel if:

Tip: Before final selection, consult your CNC machining factory about part size, machining complexity, and environmental exposure to avoid costly material mistakes.

At VMT CNC Machining, we specialize in delivering high-precision stainless steel CNC machined parts, including both 420 stainless steel (SS420) and 316 stainless steel (SS316). Our expertise ensures that each part meets your mechanical, corrosion resistance, and dimensional requirements, whether for industrial, medical, marine, or consumer applications.

Why Choose VMT:

Tip: Clearly communicate your project’s requirements (hardness, corrosion resistance, machining complexity) to VMT to achieve optimal part performance and cost efficiency.

Choosing between 420 stainless steel (SS420) and 316 stainless steel (SS316) depends on your project’s mechanical demands, environmental conditions, and cost considerations.

420 Stainless Steel is ideal for parts requiring high hardness, wear resistance, and edge retention, such as knives, molds, and industrial tools. Its lower cost and heat-treatable properties make it suitable for dry or low-corrosion environments.

316 Stainless Steel excels in corrosion resistance, toughness, and long-term durability, making it perfect for marine, chemical, food, and medical applications. Although it has a higher upfront cost and is more difficult to machine, it reduces maintenance and replacement expenses over time.

By understanding the composition, physical properties, mechanical performance, heat treatment, applications, and cost differences, engineers and designers can make informed decisions for their CNC machined parts. Partnering with a reliable CNC machining factory like VMT ensures that both SS420 and SS316 parts meet precision, quality, and performance standards, maximizing the success of your project.

1. Which is Better, SS316 or SS410?

2. Does 420 Stainless Steel Rust?

Yes, 420 stainless steel can rust if exposed to moisture, salt, or acidic environments, especially if not properly coated or maintained.

3. Which is Better, 304 or 420 Stainless Steel?

4. Which is Cheaper, 304 Stainless Steel or 316 Stainless Steel?

304 stainless steel is generally cheaper than 316 due to lower nickel and molybdenum content.

5. What is the Cheapest Grade of Stainless Steel?

430 stainless steel and 304 stainless steel are among the most affordable grades, depending on market conditions.

6. Which Stainless Steel is Best for Cooking?

304 stainless steel is widely preferred for cookware and kitchen equipment due to excellent corrosion resistance, durability, and food safety.

7. Does 420 Stainless Steel Rust?

Yes, repeated: 420 stainless steel is prone to rust if exposed to water, salt, or acidic conditions, especially without proper maintenance.

8. Which is Cheaper, 316 or 316L?

316 stainless steel is slightly cheaper than 316L, which has lower carbon content for better weldability and reduced risk of corrosion.

9. Is 430 Stainless Steel Cheaper than 304?

Yes, 430 stainless steel is generally cheaper than 304, but it has lower corrosion resistance and is magnetic.

10. What Grade of Stainless Steel is Best?

The “best” grade depends on application:

Tip: Choose stainless steel based on your environment, mechanical needs, and cost, not just popularity — this ensures your CNC machined parts perform reliably.