15 years one-stop China custom CNC machining parts factory

132 |

Published by VMT at Sep 18 2025 | Reading Time:About 3 minutes

132 |

Published by VMT at Sep 18 2025 | Reading Time:About 3 minutes

When choosing stainless steel for machining or knife making, it’s easy to get lost between grades like 440A stainless steel and 440C stainless steel. Pick the wrong one, and you may end up with parts that rust faster, dull quicker, or cost more to produce. This not only reduces durability but also increases project costs and maintenance needs.

The good news is that understanding the differences between 440A and 440C stainless steel—from chemical composition to mechanical properties—will help you choose the right material for your specific application. Whether you need stainless steel CNC machining parts or reliable steel for knives, knowing their strengths and weaknesses ensures better decisions.

440A is a lower-carbon stainless steel offering better corrosion resistance and easier machining, while 440C has higher carbon content, making it harder, stronger, and better for cutting edges. Choose 440A for affordability and corrosion resistance, and 440C for durability, wear resistance, and high-performance applications.

Now that you have a quick overview of the difference between 440A and 440C stainless steel, it’s time to explore each steel grade in detail. By understanding their definitions, properties, and uses, you’ll know exactly which material fits your project—whether you need CNC machining parts or high-performance blades.

440A stainless steel is a martensitic stainless steel with relatively low carbon content compared to other 440 grades. This lower carbon makes it easier to machine, form, and polish while still maintaining good strength. It offers excellent corrosion resistance in mild environments, which is why it’s often chosen for budget-friendly knives, medical instruments, and stainless steel CNC machining parts.

Because of its balance of machinability and resistance to rust, 440A is often the preferred choice when cost control is important, or when parts don’t require maximum hardness.

440C stainless steel is a high-carbon martensitic stainless steel known for its superior hardness and wear resistance. With the highest carbon content among the 440 series, it achieves excellent edge retention and strength after heat treatment. This makes it a popular choice for high-quality knives, bearings, valves, and precision CNC machining parts that demand durability.

Unlike 440A, 440C sacrifices some corrosion resistance for hardness and toughness, making it better suited for environments where cutting performance and wear resistance are more critical than exposure to moisture.

Although both belong to the 440 stainless steel family, 440A and 440C differ mainly in carbon content, hardness, corrosion resistance, and applications. 440A is softer, easier to machine, and more corrosion-resistant, while 440C is harder, stronger, and preferred for cutting edges and wear-resistant parts.

| Feature |

440A Stainless Steel |

440C Stainless Steel |

| Carbon Content |

Lower (softer, easier to machine) | Higher (harder, stronger, better edge retention) |

| Hardness |

Moderate hardness after heat treatment | Very high hardness after heat treatment |

| Corrosion Resistance |

Better in mild environments | Slightly lower than 440A |

| Wear Resistance |

Moderate | Excellent |

| Machinability |

Easier to machine and polish | More difficult to machine |

| Cost |

Lower, more budget-friendly | Higher due to strength and durability |

| Common Uses |

Medical tools, budget knives, CNC parts | High-end knives, bearings, valves, CNC parts |

Tip: If your project values corrosion resistance and cost savings, go with 440A. If you need maximum hardness and wear resistance, 440C is the better choice.

Both 440A and 440C are martensitic stainless steels, but they are optimized for different purposes. 440A emphasizes corrosion resistance, polishability, and affordability, while 440C focuses on hardness, wear resistance, and strength. Their chemical compositions directly affect how they perform in machining, heat treatment, and long-term use.

440A Stainless Steel vs. 440C Stainless Steel: Chemical Composition

| Element |

440A Stainless Steel (%) |

440C Stainless Steel (%) |

| Carbon (C) |

0.60 – 0.75 | 0.95 – 1.20 |

| Chromium (Cr) |

16.0 – 18.0 | 16.0 – 18.0 |

| Manganese (Mn) |

≤ 1.0 | ≤ 1.0 |

| Silicon (Si) |

≤ 1.0 | ≤ 1.0 |

| Molybdenum (Mo) |

Optional ≤ 0.75 | Optional ≤ 0.75 |

| Phosphorus (P) |

≤ 0.04 | ≤ 0.04 |

| Sulfur (S) |

≤ 0.03 | ≤ 0.03 |

The higher carbon content in 440C gives it superior hardness and edge retention, while 440A’s lower carbon improves toughness and corrosion resistance.

440A Stainless Steel vs. 440C Stainless Steel: Mechanical Properties

The mechanical properties of 440A and 440C highlight their biggest differences. 440A offers balanced strength with good toughness, while 440C delivers superior hardness and wear resistance after heat treatment. These differences explain why 440C is widely used in cutting tools and high-performance components, while 440A fits better in cost-sensitive applications.

Mechanical Properties Comparison

| Property |

440A Stainless Steel |

440C Stainless Steel |

| Hardness (HRC) |

~55 HRC (after heat treatment) | ~58–60 HRC (after heat treatment) |

| Vickers Hardness (HV) |

~160 – 190 | ~270 – 310 |

| Tensile Strength (MPa) |

~680 – 750 | ~760 – 800+ |

| Yield Strength (Rp0.2, MPa) |

~415 – 450 | ~450 – 500+ |

| Elongation (%) |

~20 – 25 | ~12 – 14 |

| Ductility (%) |

Higher than 440C | Lower than 440A |

| Reduction of Area (Z/%) |

~50% | ~35% |

| Fatigue Strength (MPa) |

~275 – 300 | ~325 – 350 |

| Elastic Modulus (GPa) |

~200 | ~200 |

| Shear Strength (MPa) |

~450 | ~520 |

Key takeaway: 440C is harder, stronger, and better for high-wear parts, while 440A is tougher, more ductile, and easier to process in a CNC machining service.

440A Stainless Steel vs. 440C Stainless Steel: Physical Properties

The physical properties of 440A and 440C stainless steel are quite similar since both belong to the same family, but small differences can affect performance in CNC machining and end-use applications. 440A’s slightly lower hardness provides better flexibility, while 440C’s density and thermal behavior make it suitable for high-stress parts.

Physical Properties Comparison

| Property |

440A Stainless Steel |

440C Stainless Steel |

| Density (g/cm³) |

~7.74 | ~7.74 |

| Melting Point (°C) |

1480 – 1530 | 1480 – 1530 |

| Specific Heat (J/kg·K) |

~460 | ~460 |

| Thermal Conductivity (W/m·K) |

~24.0 | ~24.0 |

| Thermal Expansion (10⁻⁶/K) |

~10.1 | ~10.1 |

| Electrical Resistivity (µΩ·m) |

~0.60 | ~0.60 |

| Elastic Modulus (kN/mm²) |

~200 | ~200 |

| Magnetic Properties |

Magnetic (martensitic) | Magnetic (martensitic) |

| Electrical Conductivity (% IACS) |

~2 | ~2 |

Key takeaway: The physical properties of 440A and 440C are nearly identical, but their carbon-driven mechanical properties set them apart in real-world applications.

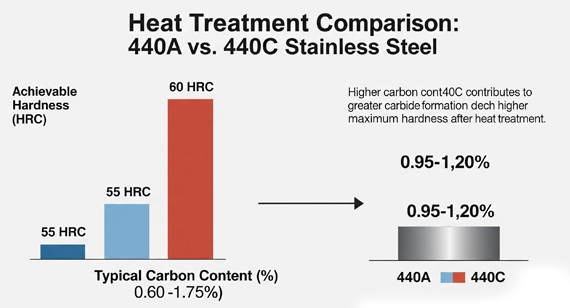

Heat treatment a critical role in defining the hardness, toughness, and wear resistance of 440A and 440C stainless steels. While both steels respond well to heat treatment, their results differ because of carbon content. 440A achieves moderate hardness with good toughness, while 440C reaches very high hardness but with reduced ductility.

| Heat Treatment Step |

440A Stainless Steel |

440C Stainless Steel |

| Annealing |

850 – 900°C, slow cooling to improve machinability | 850 – 900°C, slow cooling to reduce stresses |

| Hardening |

1010 – 1065°C, oil or air quench | 1010 – 1070°C, oil or air quench |

| Tempering |

150 – 370°C (improves toughness, reduces brittleness) | 150 – 370°C (achieves maximum hardness 58–60 HRC) |

| Final Hardness |

~55 HRC | ~58–60 HRC |

Key takeaway: 440A is easier to process with heat treatment and maintains better toughness, while 440C is chosen for maximum hardness and cutting-edge performance.

Both 440A and 440C stainless steels bring unique benefits to CNC machining and knife making. The choice depends on whether you value corrosion resistance and affordability (440A) or maximum hardness and durability (440C).

| Aspect |

440A Stainless Steel – Advantages |

440A Stainless Steel – Disadvantages |

440C Stainless Steel – Advantages |

440C Stainless Steel – Disadvantages |

| Cost |

More affordable, budget-friendly | Lower performance for heavy-duty use | Premium quality, justifies price | Higher initial cost |

| Corrosion Resistance |

Excellent in mild environments | Lower hardness, less edge retention | Good for hardened steel | Slightly weaker corrosion resistance |

| Machinability |

Easier to machine and polish | Cannot reach very high hardness | High wear resistance when treated | More difficult to machine |

| Hardness & Strength |

Balanced hardness and toughness | Wears faster under heavy loads | Superior hardness (58–60 HRC) | Lower ductility, can be brittle |

| Applications |

Medical tools, budget knives, CNC parts | Not ideal for cutting-intensive tasks | High-end knives, bearings, valves, CNC parts | Less suitable in moist or marine use |

Key takeaway: Choose 440A for affordability and corrosion resistance, and 440C for maximum hardness, edge retention, and high-performance parts.

The applications of 440A and 440C stainless steels differ because of their performance balance. 440A is chosen for cost-sensitive projects and environments where corrosion resistance is more important than hardness. In contrast, 440C is preferred for high-performance parts requiring strength, hardness, and long wear life.

| Application Type |

440A Stainless Steel |

440C Stainless Steel |

| Knives & Blades |

Budget knives, kitchen knives, diving knives | Premium knives, tactical knives, surgical tools |

| Medical Instruments |

Scalpels, scissors, basic surgical tools | High-precision cutting instruments |

| CNC Machining Parts |

Affordable stainless steel CNC machining parts | High-performance 440C stainless steel CNC machining parts |

| Industrial Components |

Springs, simple wear parts, general hardware | Bearings, valves, pumps, nozzles |

| Consumer Products |

Cutlery, scissors, decorative parts | High-end cutlery, precision tools |

Key takeaway: 440A is better for general-purpose and budget-friendly parts, while 440C is the go-to for demanding applications where wear resistance and durability are critical.

The cost difference between 440A stainless steel and 440C stainless steel comes from both raw material price and machining difficulty. 440A is cheaper and easier to machine, while 440C is more expensive and increases tool wear, raising overall production costs.

Cost Comparison Table

| Cost Factor |

440A Stainless Steel |

440C Stainless Steel |

| Material Price (per kg) |

~$2.5 – $3.5 | ~$4.0 – $6.0 |

| Machining Difficulty |

Easier to cut and polish | Harder, requires stronger tooling |

| Tool Wear |

Low (longer tool life) | High (frequent tool replacement) |

| CNC Machining Cost |

~$25 – $35 per hour (standard tooling) | ~$35 – $50 per hour (due to tool wear & hardness) |

| Heat Treatment Cost |

Moderate | Higher (to achieve max hardness 58–60 HRC) |

| Overall Cost per Part |

Lower, budget-friendly | Higher, premium but longer-lasting |

Key takeaway: 440A saves on initial material and machining costs, while 440C is more expensive upfront but delivers higher performance and longer service life.

Choosing between 440A vs 440C stainless steel depends on the balance you need between corrosion resistance, hardness, durability, and cost. Understanding your project requirements helps you select the most suitable steel for CNC machining parts, knives, or industrial components.

When Should I Use 440A Stainless Steel?

Tip: Avoid 440A for high-wear cutting edges or high-stress industrial parts, as it may dull faster.

When Should I Use 440C Stainless Steel?

Tip: Ensure your CNC machining factory is equipped to handle 440C’s hardness to avoid excessive tool wear or processing delays.

Both 440A and 440C stainless steels are used in knife making, but their suitability depends on edge retention, corrosion resistance, and overall performance. Choosing the right steel ensures your knife maintains sharpness, resists rust, and fits your intended use.

Is 440A Stainless Steel Suitable for Knives?

Tip: If you need a knife that is easy to maintain and resists corrosion, 440A is a good choice, but avoid heavy-duty cutting tasks.

Is 440C Stainless Steel Suitable for Knives?

Tip: Regular cleaning and oiling of 440C knives can maintain corrosion resistance and extend lifespan, especially in humid environments.

Key takeaway: 440A is better for ease of maintenance and corrosion resistance, while 440C is best for high-performance knives requiring sharpness and durability.

At VMT, we specialize in producing high-quality 440A stainless steel CNC machining parts and 440C stainless steel CNC machining parts for a wide range of industries. Our factory combines advanced CNC machinery with skilled technicians to ensure precision, repeatability, and consistent quality in every part.

Tip: When ordering CNC machining parts from VMT, specify your material and application requirements (440A or 440C) to ensure the finished parts meet your expectations.

Choosing between 440A stainless steel and 440C stainless steel comes down to your project priorities. 440A offers excellent corrosion resistance, easier machining, and affordability, making it ideal for general-purpose knives, medical instruments, and cost-sensitive CNC machining parts. In contrast, 440C provides superior hardness, wear resistance, and edge retention, making it the top choice for high-performance knives, industrial components, and precision CNC parts.

By understanding their chemical composition, mechanical and physical properties, heat treatment, and cost differences, you can make an informed decision that balances durability, performance, and budget. Whether you need stainless steel CNC machining parts or high-end cutting tools, selecting the right steel ensures optimal results and long-term reliability.

1. What is the difference between 440B and 440C stainless steel?

440B has slightly lower carbon content than 440C, making it softer and easier to machine, but with less hardness and edge retention. 440C is harder, more wear-resistant, and ideal for high-performance applications like knives and bearings.

2. Is 440A steel good?

Yes, 440A is good for applications requiring corrosion resistance, moderate hardness, and easy machining, such as budget knives, medical tools, and general-purpose CNC machining parts.

3. Is 304 stainless steel better than 440 stainless steel?

It depends on the use. 304 stainless steel has superior corrosion resistance but lower hardness. 440 series steels (like 440A or 440C) are much harder and better for cutting, wear-resistant parts, and knives.

4. Does 440C stainless steel rust?

440C is corrosion-resistant but not completely rust-proof. In humid or marine environments, it may develop rust if not cleaned or oiled properly.

5. What is the highest quality stainless steel?

For hardness and wear resistance, 440C is considered top-quality among martensitic stainless steels. For corrosion resistance, 316 or 304 stainless steel is superior. The “best” depends on your application needs.

6. Is 440A better than 440C?

440A is better for corrosion resistance, ease of machining, and lower cost. 440C is better for hardness, edge retention, and wear resistance. The choice depends on whether performance or corrosion resistance is your priority.

7. Is 440A easy to sharpen?

Yes, 440A is easier to sharpen than 440C because of its lower carbon content and moderate hardness.

8. What is the hardest steel for knives?

Among common stainless steels, 440C, VG10, and some powdered metallurgy steels are very hard. 440C offers a good balance of hardness and corrosion resistance for knives.

9. Which is better, 304 or 400 stainless steel?

304 is better for corrosion resistance and general-purpose applications. 400 series (including 440A/440C) is better for hardness, cutting edges, and wear-resistant parts.

10. What is the difference between 440B and 440A?

440B has slightly higher carbon content than 440A, making it harder and better for wear resistance, but still softer than 440C. 440A is easier to machine and more corrosion-resistant.

11. Which is better, Japanese or German steel?

Both have high-quality steels. Japanese steels often focus on hardness and sharpness (VG10, Aogami), while German steels emphasize toughness and corrosion resistance (440C, X50CrMoV). The “better” choice depends on the intended knife performance.

12. Can 440A and 440C stainless steel be welded?

Yes, both can be welded, but 440C requires caution due to its high carbon content. Preheating and post-weld heat treatment are often needed to prevent cracking and maintain hardness. 440A is easier to weld than 440C.