15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 07 09

2024 07 09 Titanium, a metallic element, is renowned for its unique physical and chemical properties and wide range of applications. This article will explore the definition, origin, characteristics, grades, and uses of titanium, as well as common questions related to it, providing comprehensive and professional knowledge for experts in the CNC machined parts manufacturing field.

66

66

Read more

Read more

VMT

VMT  2024 07 08

2024 07 08 Selecting rust-free metal materials is crucial in the field of CNC machining parts manufacturing. Rust not only affects the aesthetics of the product but can also severely compromise its performance and lifespan. This article aims to delve into the causes of metal rust, the difference between corrosion and rust, and provide a detailed introduction to a series of rust-free metals, their characteristics, and applications, offering a comprehensive options guide for the CNC machining industry.

66

66

Read more

Read more

VMT

VMT  2024 07 07

2024 07 07 Red copper, as the pure form of the metal copper, is widely used in electronics, construction, art crafts, and CNC machining due to its excellent electrical conductivity, thermal conductivity, and plasticity. Understanding the melting point of red copper is crucial for mastering its processing technology, optimizing production processes, and ensuring product quality. This article aims to provide a comprehensive analysis of the melting point of red copper, covering its definition, influencing factors, melting point characteristics of different types of red copper, and comparisons with the melting points of other metals. Additionally, we will discuss its practical applications in CNC machining, providing readers with a detailed guide.

66

66

Read more

Read more

VMT

VMT  2024 07 06

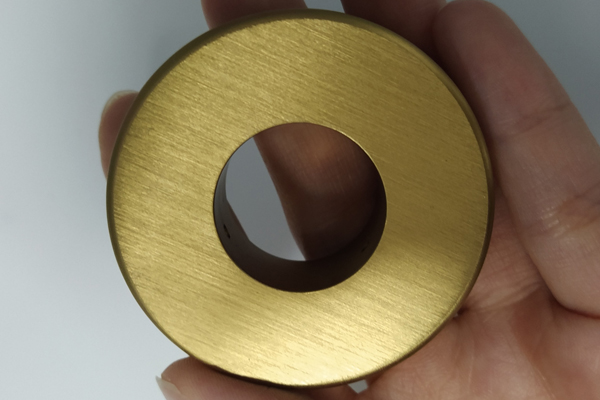

2024 07 06 In the field of CNC machined parts manufacturing, brass is a favored metal material due to its excellent machinability, corrosion resistance, and aesthetic appeal. Among them, brushed brass stands out in various applications due to its unique surface texture and tactile feel. This article aims to delve into all aspects of brushed brass, from the brushing process, factors affecting surface finish, the brushing process itself, typical applications, the pros and cons of its use in CNC machining, to custom techniques and common FAQs in VMT's manufacturing and processing services, providing you with comprehensive knowledge and insights.

66

66

Read more

Read more

VMT

VMT  2024 07 05

2024 07 05 In the field of CNC machining and component manufacturing, brass is a popular metal material due to its excellent machining properties and attractive golden appearance. However, achieving the desired smoothness and aesthetics for brass CNC machined parts requires effective polishing techniques. This article provides a comprehensive guide to polishing brass, covering the preparation of polishing tools, pre-polishing cleaning, the polishing process, different types of polishing surface treatments along with their advantages and disadvantages, applications of polished brass CNC machined parts, and answers to common questions. The goal is to offer a thorough and professional guide for polishing brass.

66

66

Read more

Read more

VMT

VMT  2024 07 04

2024 07 04 The melting point, the fixed temperature at which a substance transitions from a solid to a liquid state, is a fundamental concept in materials science. For metallic materials, the melting point is directly related to machining difficulty, operating temperature range, and thermal stability. As an alloy of copper and zinc, the melting point of brass varies depending on its composition.

66

66

Read more

Read more

VMT

VMT  2024 07 03

2024 07 03 Brass, an alloy of copper and zinc, has distinct physical and chemical properties compared to pure copper or zinc. Importantly, brass does not contain iron, meaning it does not rust in the same way iron does (i.e., forming iron oxide). However, brass can undergo a chemical process called "oxidation" under certain conditions, leading to a change in surface color and the formation of a dark yellow or greenish oxide layer, often mistaken for rust.

66

66

Read more

Read more

VMT

VMT  2024 07 02

2024 07 02 In the field of CNC machined parts manufacturing, aluminum and stainless steel are two common metal materials, each with unique characteristics and broad application scenarios. This article aims to comprehensively compare aluminum and stainless steel in terms of elemental composition, physical properties, machinability, and applications, helping readers make more reasonable and scientific decisions when choosing materials.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!