15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 07 25

2024 07 25 8020 aluminum and 2020 aluminum (assuming similar to 2024 aluminum) each have their strengths in the field of CNC machining parts manufacturing. The choice depends on your specific needs, application scenarios, and expectations for material performance. By thoroughly understanding the characteristics, advantages, disadvantages, and application fields of both materials, and combining professional consultation and customized services, you can make an informed choice and lay a solid foundation for the success of your project.

66

66

Read more

Read more

VMT

VMT  2024 07 24

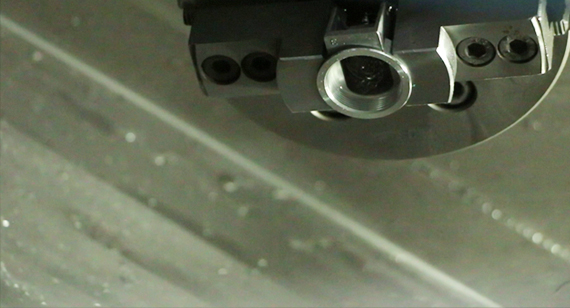

2024 07 24 In the field of CNC machining parts manufacturing, blind holes and through holes are two basic yet essential machining types widely used in circuit boards, mechanical parts, aerospace components, and more. This article will comprehensively explain the basic concepts, differences, manufacturing processes, design considerations, measurement and inspection techniques, and engineering applications of blind holes and through holes, aiming to provide readers with thorough and in-depth professional knowledge.

66

66

Read more

Read more

VMT

VMT  2024 07 23

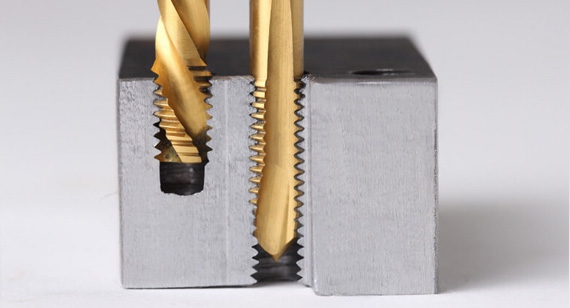

2024 07 23 In the field of CNC machining parts manufacturing, threads play a crucial role as important elements for connection and fastening. Their design and machining are vital. This article aims to delve into the definitions, differences, main parameters, machining tools, types, and applications of external and internal threads. Through detailed analysis, it will help readers fully understand these two thread forms and enhance their professional skills in CNC machining.

66

66

Read more

Read more

VMT

VMT  2024 07 22

2024 07 22 Cast aluminum, a crucial member of the metal casting processes, refers to the process of injecting molten aluminum or aluminum alloy into molds, cooling and solidifying it to form aluminum parts of the desired shape. Due to its unique physical and chemical properties, cast aluminum is widely used in various industrial fields. This article provides an in-depth guide for experts and practitioners in the CNC machining parts manufacturing industry, covering the definition of cast aluminum, its advantages, comparison with other metal materials, different casting processes, common casting aluminum alloys, methods for choosing casting processes, surface treatments for cast aluminum parts, application fields, and common issues.

66

66

Read more

Read more

VMT

VMT  2024 07 21

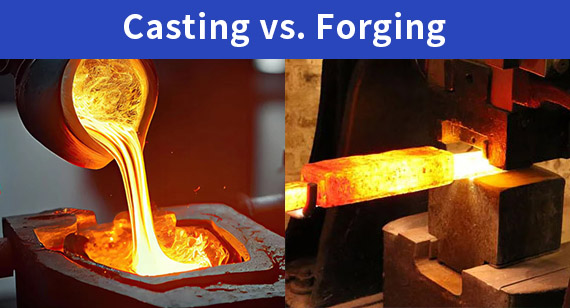

2024 07 21 Casting and forging are two important and complementary processes in the metalworking industry. They have significant differences in raw material handling, process methods, product characteristics, and application ranges. Casting involves melting metal and pouring it into a mold to cool and solidify into shape, making it suitable for producing complex shapes, large quantities, and low-cost parts. Forging, on the other hand, uses pressure to deform solid metal plastically, ideal for manufacturing high-strength, high-precision, and relatively simple-shaped components. This article will delve into the differences between these two processes, their respective advantages, and factors to consider when choosing between them.

66

66

Read more

Read more

VMT

VMT  2024 07 20

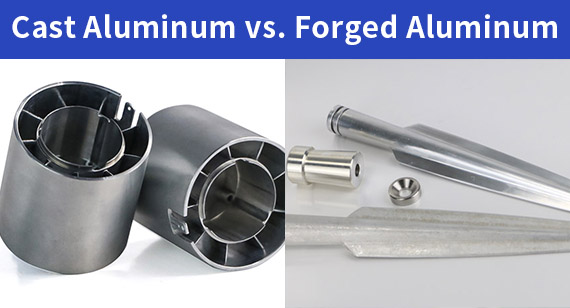

2024 07 20 In the field of CNC machining parts manufacturing, cast aluminum and forged aluminum are two primary forms of aluminum materials, each with unique characteristics and application scenarios. Cast aluminum is obtained through casting processes, making it suitable for mass production of complex-shaped parts; forged aluminum, processed through forging, boasts higher strength and toughness, ideal for demanding performance requirements. This article provides an in-depth comparison of cast aluminum and forged aluminum from multiple dimensions, helping readers better understand their differences and make informed choices in practical applications.

66

66

Read more

Read more

VMT

VMT  2024 07 19

2024 07 19 In the field of CNC machining parts manufacturing, aluminum extrusions are widely used in various industrial and non-industrial applications due to their lightweight, high strength, ease of machining, and cost-effectiveness. Among these, 2020, 4040, and 8020 aluminum extrusions are some of the most popular specifications, each exhibiting different advantages and characteristics in terms of structural design, load-bearing capacity, and versatility. This article provides an in-depth comparative analysis of these three aluminum extrusions to help readers choose the appropriate material based on specific needs.

66

66

Read more

Read more

VMT

VMT  2024 07 18

2024 07 18 Metal sheet welding is a crucial aspect of CNC part manufacturing. By employing welding techniques, separate metal sheets are joined together to meet various mechanical and structural requirements. This article provides an in-depth look at common welding methods, techniques, types of metals used in welding, tips, and factors to consider when selecting a welding method. It aims to offer readers comprehensive and professional knowledge.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!