15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 08 10

2024 08 10 Taps are essential tools in the field of CNC machining for producing internal threads. This article aims to provide a comprehensive overview of tap types, features, applications, and selection methods, serving as a detailed reference for experts and operators in CNC machining. Readers will gain insights into the basic structure of taps, suitable scenarios for different types of taps, standard tap markings, usage precautions, and common troubleshooting tips. This knowledge will help users master tap usage techniques, improve machining efficiency, and enhance product quality.

66

66

Read more

Read more

VMT

VMT  2024 08 09

2024 08 09 Screen printing, also known as silk screen printing, is a widely used printing technique that employs a mesh screen as a stencil. Ink is forced through the mesh by a squeegee onto various surfaces. Due to its flexibility, cost-effectiveness, and high-quality print results, screen printing is extensively applied across numerous industries. This article will delve into the screen printing process, types, advantages, and applications, and will compare it to other printing methods, aiming to provide CNC machining professionals and industry experts with a comprehensive understanding.

66

66

Read more

Read more

VMT

VMT  2024 08 08

2024 08 08 Threads play a crucial role in CNC machining for parts manufacturing, serving as essential elements for connection, transmission, and sealing. Understanding the types of threads and their geometric parameters is vital for ensuring machining precision, connection reliability, and performance. This article begins with the definition of threads and explores their geometric parameters, characteristics of different thread types, tools and methods for identifying threads, and essential tips for selecting the correct threads. Additionally, it addresses common questions about thread types and geometric parameters.

66

66

Read more

Read more

VMT

VMT  2024 08 07

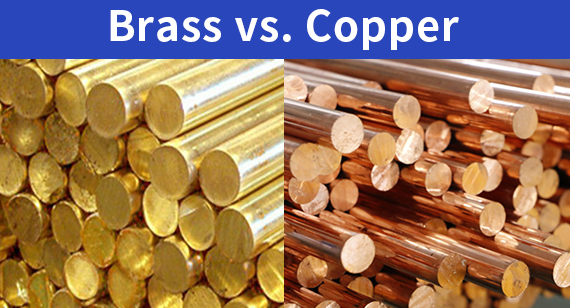

2024 08 07 Brass and copper, while often confused due to their similar names, differ significantly in their material properties, applications, and processing methods. This article explores these differences in detail, covering ten key aspects: elemental composition, corrosion resistance, weight, durability, machinability, weldability, conductivity, strength, appearance, and hardness. It also includes an overview of red copper and brass, quick identification methods, factors affecting their longevity, and recommendations for material selection in projects.

66

66

Read more

Read more

VMT

VMT  2024 08 06

2024 08 06 4140 alloy steel, also known as AISI 4140 or UNS G41400, is a widely used low-alloy high-strength steel. By adding alloying elements such as chromium, molybdenum, and manganese, the mechanical properties and heat treatment response of the base steel are significantly enhanced. This steel is known for its excellent strength, good toughness, and machinability, making it a key material in various industrial sectors.

66

66

Read more

Read more

VMT

VMT  2024 08 05

2024 08 05 A rivet is a special type of fastener composed of a head and a shank, used to connect two parts or components with through-holes. Its working principle is to achieve a secure connection between parts through the self-deformation or interference fit of the rivet. Rivets are widely used in various industries, including automotive manufacturing, shipbuilding, aerospace, construction, and are an indispensable part of mechanical engineering.

66

66

Read more

Read more

VMT

VMT  2024 08 04

2024 08 04 Titanium, known for its high strength, low density, and corrosion resistance, is extensively used across industries such as aerospace, medical, automotive, marine engineering, and jewelry. However, due to its high hardness and silver-gray appearance, machining and polishing titanium becomes a challenging task. This article will delve into the steps, types, benefits, applications, and surface treatment methods of titanium polishing, providing comprehensive guidance for experts and practitioners in the field of CNC machined parts manufacturing.

66

66

Read more

Read more

VMT

VMT  2024 08 03

2024 08 03 Fasteners play a crucial role in connecting two or more parts in various fields such as machinery, construction, automotive, and aerospace. They ensure stable connections between components through mechanisms such as friction, locking, or welding, resisting external forces and maintaining structural integrity and functionality. This article explores the different types of fasteners and their applications, while also discussing materials, surface treatments, and selection principles to provide comprehensive guidance for professionals in the CNC machining sector.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!