15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 09 08

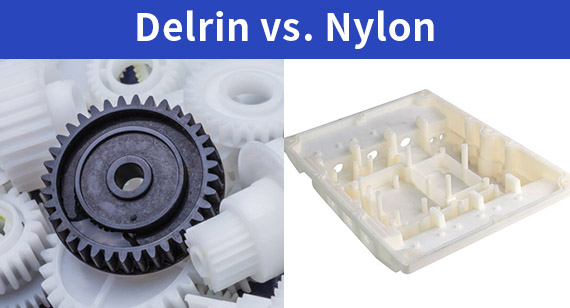

2024 09 08 In the world of CNC machining and manufacturing, choosing the right material is crucial for the success of a project. Delrin and Nylon are two of the most popular engineering plastics used in a wide range of applications, from automotive components to consumer products. Each material offers unique properties, advantages, and limitations that make them suitable for specific applications. This article provides a detailed comparison of Delrin and Nylon, exploring their material properties, processability, and common applications. By understanding the differences between these two polymers, manufacturers can make informed decisions for their precision CNC machining projects.

66

66

Read more

Read more

VMT

VMT  2024 09 07

2024 09 07 Aluminum alloys are among the most versatile materials in the manufacturing industry, offering a unique combination of light weight, strength, and corrosion resistance. These properties make them ideal for a wide range of applications, from aerospace to consumer goods. This article provides a comprehensive overview of aluminum alloys, exploring their types, characteristics, and applications. By understanding the different aluminum alloy types and their properties, manufacturers can select the most suitable material for precision CNC machining parts, ensuring optimal performance in their custom CNC machining projects.

66

66

Read more

Read more

VMT

VMT  2024 09 06

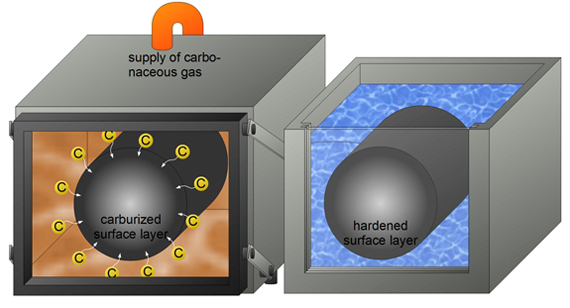

2024 09 06 Surface hardening is a crucial process in manufacturing, particularly in the production of CNC machining parts, where durability, strength, and wear resistance are critical. It involves altering the surface layer of a material, usually metal, to increase its hardness while maintaining a softer, ductile interior. This guide provides an in-depth look at surface hardening, explaining what it is, why it’s done, when it’s used, and how it benefits various applications. By understanding surface hardening, manufacturers can enhance the performance and longevity of precision CNC machining parts.

66

66

Read more

Read more

VMT

VMT  2024 09 05

2024 09 05 Tapping and threading are fundamental processes in the world of CNC machining, each essential for creating threaded holes used in assembling components with screws, bolts, or other fasteners. While they may seem similar, tapping and threading differ significantly in technique, tools, and applications. This article provides a detailed comparison between tapping and threading, exploring their differences, similarities, advantages, and limitations. By understanding these processes, manufacturers and engineers can make informed decisions to achieve optimal results in CNC machining, whether in mass production or custom CNC machining projects.

66

66

Read more

Read more

VMT

VMT  2024 09 04

2024 09 04 Threaded holes are fundamental elements in engineering and manufacturing, providing a means for assembling and securing parts with bolts, screws, or other fasteners. This comprehensive guide explores the intricacies of machining threaded holes, including the types, features, and processing technologies involved. Additionally, it covers the advantages and disadvantages of threaded holes, their applications across various industries, and the differences between drilling, tapping, and threading. By understanding these aspects, manufacturers and engineers can optimize their processes, ensuring precision and durability in CNC machined parts.

66

66

Read more

Read more

VMT

VMT  2024 09 03

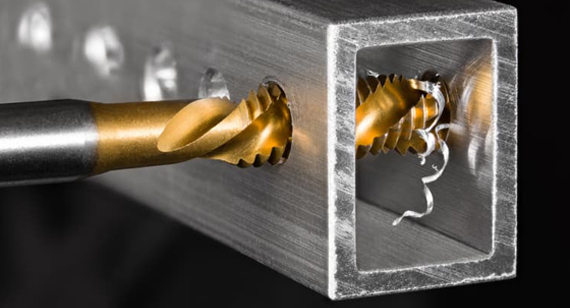

2024 09 03 Flying cutters, also known as fly cutters, are essential tools in the world of CNC machining. They are used to produce smooth, flat surfaces on a workpiece, often with high precision and at a lower cost compared to other cutting tools. This guide provides an in-depth look at flying cutters, their types, components, specifications, and uses, as well as their advantages and how they compare to other cutting tools like face milling cutters. By understanding the various aspects of flying cutters, manufacturers and machinists can make informed decisions, ensuring the highest quality and efficiency in their CNC machining projects.

66

66

Read more

Read more

VMT

VMT  2024 09 02

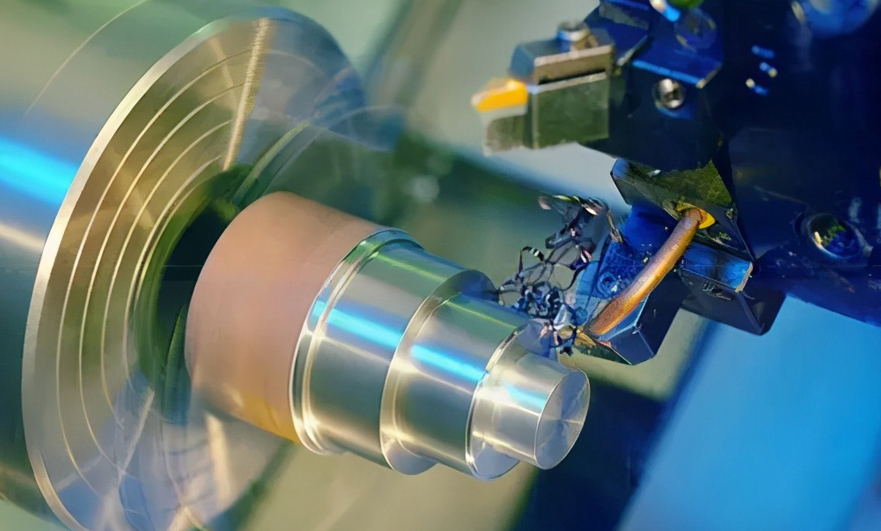

2024 09 02 Lathe cutting tools are essential components in CNC machining, playing a crucial role in shaping, cutting, and finishing precision CNC machined parts. The selection of the right lathe cutting tool, based on the material, geometry, and specific application, significantly impacts the quality and efficiency of machining processes. In this comprehensive guide, we will explore the types, applications, geometry, and precautions associated with lathe cutting tools. Understanding these aspects will enable manufacturers, machinists, and engineers to make informed decisions, ensuring optimal performance in custom CNC machining and other precision machining operations.

66

66

Read more

Read more

VMT

VMT  2024 09 01

2024 09 01 Black oxide coating is a widely used surface treatment process in the manufacturing industry, particularly for CNC machined parts. It is a conversion coating for ferrous materials that offers corrosion resistance, reduced light reflection, and an enhanced aesthetic appearance. This guide provides a comprehensive overview of black oxide coating, discussing its purpose, application process, types, materials suitable for black oxidation, and its advantages and disadvantages. The information will help manufacturers and engineers make informed decisions about when and how to use black oxide coatings in their custom CNC machining projects.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!