15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

102 |

Published by VMT at Apr 10 2024

102 |

Published by VMT at Apr 10 2024

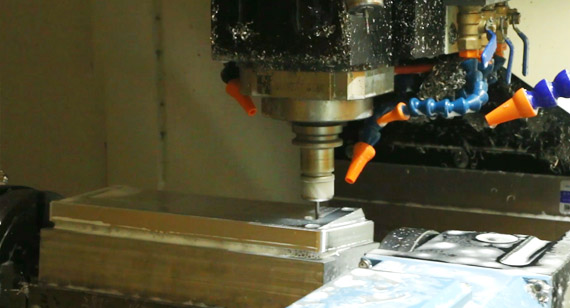

As manufacturing industries continue to evolve, CNC machining of precision parts has become an indispensable aspect of modern industrial processes. Particularly in the machining of box-type parts, the application of CNC technology is crucial. When machining box-type precision parts in CNC machining factories, strict adherence to a series of machining method considerations is essential to ensure the accuracy, quality, and production efficiency of the parts.

1. Analysis of Part Drawings and Process Planning:

Before commencing CNC precision part machining, a thorough analysis of the part drawings is indispensable. This includes a comprehensive understanding of the part's shape, dimensions, material characteristics, and machining accuracy requirements. Based on the drawing information, CNC machining factories need to develop rational machining process plans, specifying machining sequences, tool selection, fixture design, and cutting parameters.

For box-type parts, optimization of machining paths is crucial during process planning to reduce idle travel and enhance machining efficiency. Additionally, machining the edges and internal structures of the box poses challenges, requiring suitable tooling and cutting parameters to ensure machining quality.

2. Selection and Calibration of CNC Machine Tools:

CNC machining factories should select CNC machine tools suitable for machining box-type parts based on the parts' machining requirements. Considerations include precision, rigidity, stability, and machining range. After selecting the machine tools, meticulous calibration is necessary, including precision calibration of machine tool axes, tool library adjustments, and parameter settings in the CNC system, to ensure the machines operate at optimal levels.

3. Tool Selection and Optimization of Cutting Parameters:

Tooling is a critical factor in CNC precision part machining. For machining box-type parts, tool selection should consider factors such as material hardness, surface roughness requirements, and cutting force. Proper tool selection significantly improves machining efficiency and part quality.

Simultaneously, optimization of cutting parameters is vital during the machining process. Rational selection of cutting speeds, feed rates, and cutting depths effectively reduces cutting forces, minimizes tool wear, and enhances machining accuracy.

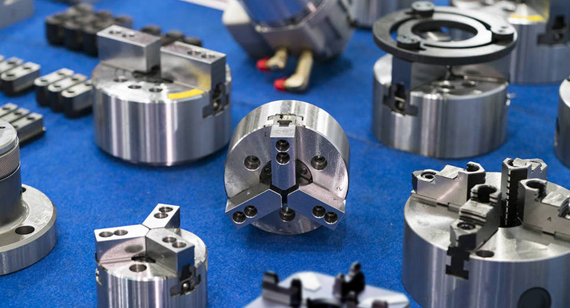

4. Fixture Design and Workpiece Clamping:

Fixture design is crucial for ensuring the machining accuracy of box-type parts. Fixtures should securely hold the workpieces, preventing movement or deformation during machining. Fixture design should also consider ease of operation and rapid workpiece exchange.

During workpiece clamping, ensuring the correct positioning and orientation of the workpiece and minimizing clamping errors are essential. For structurally complex box-type parts, specialized fixtures or custom designs may be necessary to meet machining requirements.

5. Programming and Program Verification:

Programming is key to achieving efficient, high-quality machining in CNC precision part manufacturing. Programmers should use professional CNC programming software based on part drawings and process plans. During programming, special attention should be given to optimizing machining paths, setting tool compensation, and adjusting machining parameters.

After programming, program verification is essential. This can be achieved through simulation software or trial cutting on test beds. Program verification aims to check the correctness and feasibility of the program, promptly identifying and correcting any errors to ensure smooth machining during formal production.

6. Monitoring and Adjustment during Machining:

Real-time monitoring and adjustment of machining conditions are indispensable during CNC precision part machining. Operators should closely monitor machine tool operation, tool wear, and real-time feedback on machining quality. Upon detecting any abnormalities, timely adjustments or machine stoppages should be implemented to prevent quality issues with the parts.

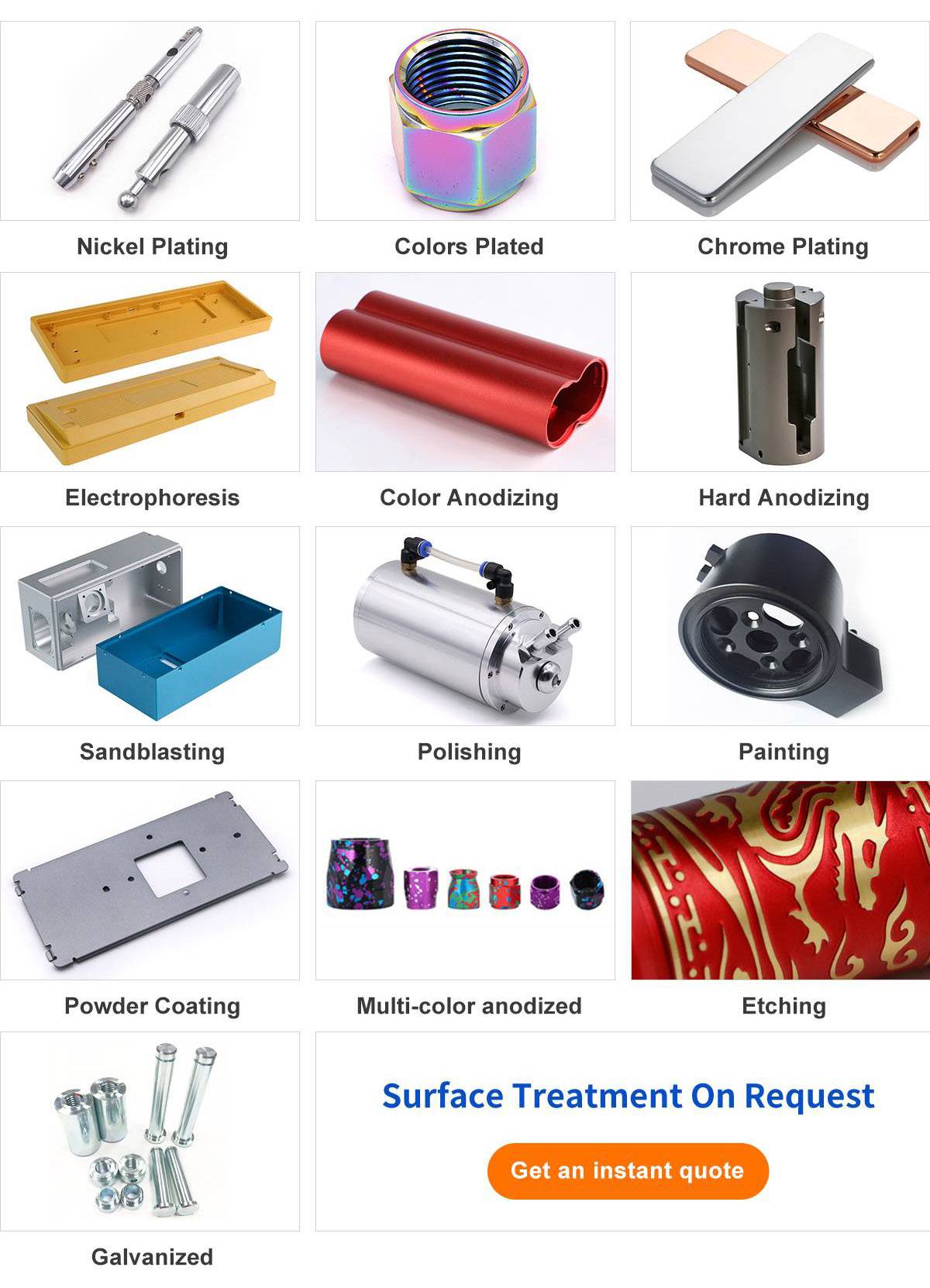

7. Quality Inspection and Surface finishing:

After machining completion, quality inspection of box-type CNC precision parts is the final checkpoint to ensure part quality. Quality inspection should cover aspects such as dimensions, shapes, surface roughness, and material properties. For non-conforming parts, prompt rework or scrapping should be undertaken.

Additionally, for parts requiring post-processing such as surface coating or heat treatment, these processes should be carried out promptly after machining to meet the final usage requirements of the parts.

In conclusion, machining box-type CNC precision parts is a complex and meticulous process, requiring strict control and management at various stages in CNC machining factories. Through rational process planning, precise machine tool calibration, optimized tool selection, stable fixture design, correct programming and verification, rigorous monitoring and inspection, and continuous research into new machining technologies and methods, CNC machining factories can ensure that the machining quality and production efficiency of box-type CNC precision parts reach optimal levels.

As experts in the field of CNC machining part manufacturing, we should continuously delve into new machining technologies and methods to drive the development and innovation of CNC precision part machining technology, contributing our wisdom and efforts to the progress of modern manufacturing industries.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!