15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

134 |

Published by VMT at Sep 04 2023

134 |

Published by VMT at Sep 04 2023

What are the problems in CNC machining watch cases?

When machining watch cases using CNC (Computer Numerical Control) machining, several challenges and issues may arise due to the intricacy and precision required in watchmaking. Here are some common problems encountered during CNC machining of watch cases:

Material Selection: The choice of material for the watch case, such as stainless steel, titanium, gold, or ceramic, affects the machining process. Different materials have varying hardness levels, which can impact tool wear and machining speed.

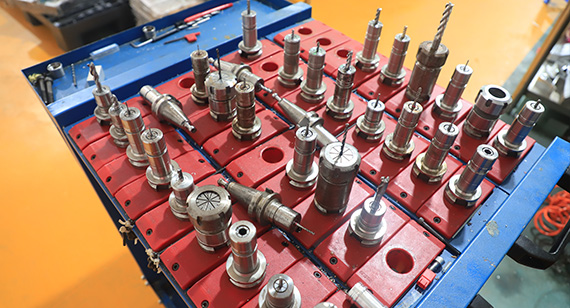

Tool Wear: The high precision required in watchmaking can lead to rapid tool wear, especially when working with hard materials. Frequent tool changes may be necessary to maintain machining quality.

Tolerances and Dimensions: Achieving the tight tolerances and precise dimensions necessary for watch cases can be challenging. CNC machines must be meticulously calibrated and maintained to ensure accuracy.

Surface Finish: Watch cases demand an impeccable surface finish. Achieving a polished and mirror-like finish requires not only precise machining but also skilled manual polishing and finishing work.

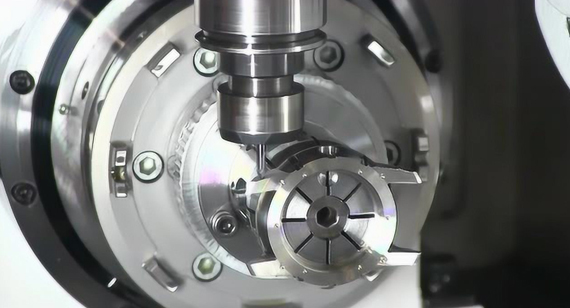

Complex Geometries: Watch cases often feature intricate shapes, curves, and bevels. Programming CNC machines to accurately machine these complex geometries can be time-consuming and require advanced CAD/CAM software.

Prototyping and Small Batch Production: Many watch models are produced in limited quantities. Setting up CNC machines for small-batch production can be less efficient compared to mass production processes.

Deburring and Polishing: After machining, watch cases typically require deburring to remove sharp edges and polishing to achieve the desired finish. Manual polishing may be needed for fine details.

Customization: Customized or limited-edition watches may require unique case designs, adding complexity to the CNC machining process and necessitating specialized programming and tooling.

Water Resistance: Achieving water resistance is crucial for watch cases. CNC machining must be precise to ensure proper fit and alignment of gaskets, seals, and case components.

Quality Control: Stringent quality control is essential in watchmaking. Each watch case must undergo rigorous inspection to verify that it meets specified tolerances, dimensions, and finish quality.

Cost Considerations: High-precision CNC machining, finishing, and quality control can be time-consuming and expensive. Balancing production costs with the desired level of craftsmanship is a critical consideration for watch manufacturers.

CAD/CAM Integration: Efficient communication between CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems is crucial for translating design specifications into precise machining instructions.

Watch case manufacturers invest in highly skilled machinists, advanced CNC machinery, and quality control measures to address these challenges and produce timepieces of exceptional quality and precision. CNC machining plays a pivotal role in the production of intricate watch cases that meet the demanding standards of the watchmaking industry.

FAQs

How long does it take to CNC machine a watch casing?

The time varies depending on complexity, material, and machining speed, but it can range from a few hours to several days.

What materials are commonly used for watch casings in CNC machining?

Stainless steel, titanium, and various alloys are popular choices, with some luxury watches even using precious metals like gold.

How do manufacturers ensure the perfect fit for the watch movement?

Tight tolerances, precise measurements, and rigorous quality control are key factors in achieving the perfect fit.

Is CNC machining the only method for crafting watch casings?

While CNC machining is a popular choice, some manufacturers may opt for traditional methods like handcrafting for limited-edition timepieces.

What role does CNC machining play in watch customization?

CNC machining allows for intricate and personalized designs, making it essential for creating unique, bespoke watch casings.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!