15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 06 23

2024 06 23 In the field of CNC machined parts manufacturing, stainless steel is a crucial material widely used in various equipment and products. However, the question of whether stainless steel is magnetic often causes confusion and discussion. This article will explore the mysteries of stainless steel magnetism, answer readers' questions, and introduce the applications of non-magnetic stainless steel in various fields.

66

66

Read more

Read more

VMT

VMT  2024 06 22

2024 06 22 In the field of CNC machining, the choice of materials is crucial for the performance, cost, and processing of products. Aluminum, as a lightweight and high-strength metal, is widely used in aerospace, automotive, electronics, and other industries. However, the question of whether aluminum possesses magnetic properties often arises. This article will delve into the scientific perspective on aluminum's magnetic properties and its applications in CNC machining.

66

66

Read more

Read more

VMT

VMT  2024 06 21

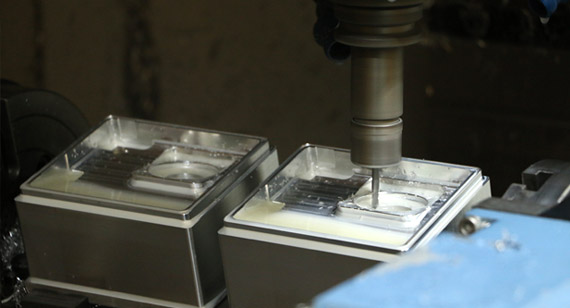

2024 06 21 In the field of CNC machining, cutting aluminum is a crucial technique. Aluminum, known for its light weight, high strength, and corrosion resistance, is widely used in industries such as aerospace, automotive, and electronics. This article provides a detailed overview of 12 professional methods and techniques for CNC cutting aluminum, aimed at helping readers better master the manufacturing technology of aluminum CNC machined parts, improving production efficiency and product quality.

66

66

Read more

Read more

VMT

VMT  2024 06 20

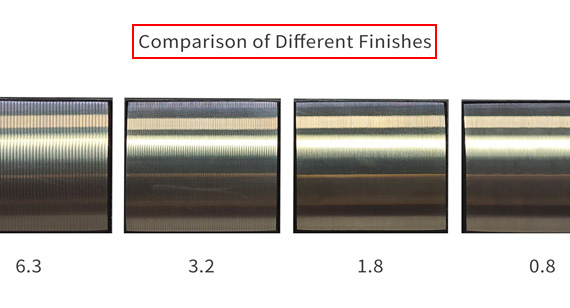

2024 06 20 In the field of CNC machining parts manufacturing, surface smoothness and surface roughness are important indicators of part quality. Ra and Rz are commonly used surface roughness parameters, each with specific definitions and application scenarios. This article will provide a detailed comparison of Ra surface smoothness and Rz surface roughness, exploring their differences, measurement methods, implementation techniques, and applications in various industries, while also addressing some common questions.

66

66

Read more

Read more

VMT

VMT  2024 06 19

2024 06 19 In the field of CNC machining parts manufacturing, aluminum is widely used due to its light weight and high strength. However, whether aluminum CNC parts rust is a concern for many engineers and manufacturers. This article will explore the reasons behind aluminum CNC parts rusting, methods to prevent it, and comparisons with other materials.

66

66

Read more

Read more

VMT

VMT  2024 06 18

2024 06 18 Aluminum anodizing, as a widely used surface treatment technique, not only enhances the corrosion resistance and wear resistance of aluminum and aluminum alloy materials but also provides them with various aesthetic appearances. However, the cost of anodizing is influenced by multiple factors. This article will explore the advantages of aluminum anodizing, discuss the key factors determining its cost, and propose techniques to enhance the anodizing effect.

66

66

Read more

Read more

VMT

VMT  2024 06 17

2024 06 17 Stainless steel, as an indispensable material in modern industry, is widely acclaimed for its excellent corrosion resistance and versatile application performance. In the field of CNC machining parts manufacturing, the use of stainless steel is particularly common. This article will comprehensively introduce the basic knowledge, characteristics, advantages and disadvantages, application scenarios, as well as precautions in the use and processing of stainless steel materials, helping readers to gain a deeper understanding of stainless steel processing materials.

66

66

Read more

Read more

VMT

VMT  2024 06 16

2024 06 16 Aluminum, as the most abundant metal element in the Earth's crust, plays an indispensable role in modern industry due to its unique physical and chemical properties. With its silver-white appearance, lightweight, excellent conductivity and thermal conductivity, and outstanding corrosion resistance, aluminum is widely used in various industries. In the field of CNC machining parts manufacturing, aluminum materials are favored for their superior machinability and low cost.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!