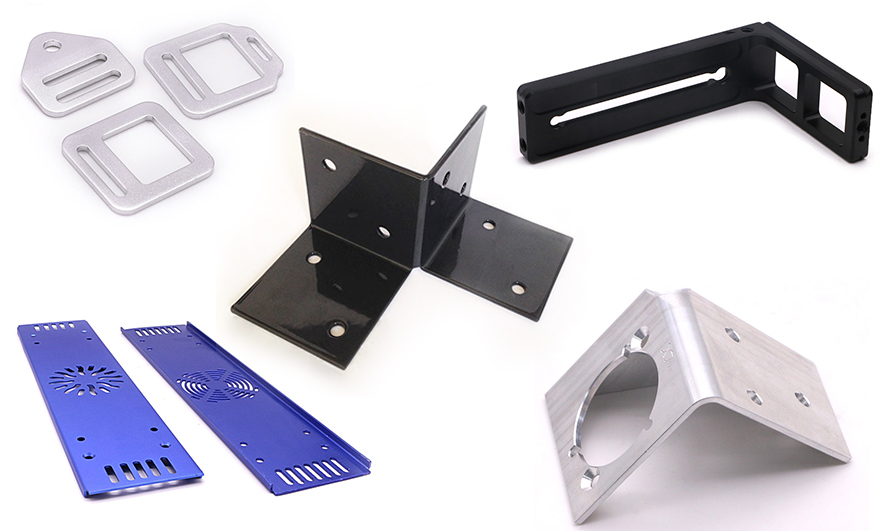

15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 05 30

2024 05 30 This article explores in depth the differences between rapid CNC machining and traditional CNC machining, including processing speed, efficiency, accuracy, scope of application, and cost control. The article also introduces in detail the application fields, processing procedures and professional skills of rapid CNC machining, and looks forward to the future development trend of rapid CNC machining technology.

66

66

Read more

Read more

VMT

VMT  2024 05 29

2024 05 29 This article provides a comprehensive analysis of rapid CNC machining technology, including its definition, working principles, manufacturing process, advantages, characteristics, and application scenarios. It also explores the types and selection methods of rapid CNC machining machines, and answers common questions regarding machining precision, cost, operational safety, and process parameter optimization.

66

66

Read more

Read more

VMT

VMT  2024 05 28

2024 05 28 With the continuous advancement of medical technology, the design and manufacture of medical devices have become increasingly precise and complex. Medical grade plastics, as a crucial material in the manufacturing of medical devices, have garnered significant attention in the industry due to their safety, reliability, and functionality. This article aims to explore the safety of medical grade plastics, the reasons for choosing polymers for medical applications, the common types of thermoplastics used in medical injection molding, and the advantages of medical grade plastics in the healthcare industry.

66

66

Read more

Read more

VMT

VMT  2024 05 27

2024 05 27 Within the vast landscape of manufacturing, sheet metal fabrication occupies an indispensable position due to its unique process characteristics and wide application areas. From simple metal sheets to complex structural components, sheet metal fabrication technology continues to drive the development of the manufacturing industry. This article delves into the definition, processes, types of techniques, material selection, surface treatment options, design considerations, and Design for Manufacturing (DfM) techniques in sheet metal fabrication, while exploring the necessity of top-tier sheet metal manufacturing.

66

66

Read more

Read more

VMT

VMT  2024 05 26

2024 05 26 In modern industry, aluminum CNC machined parts are widely used due to their lightweight, high strength, and excellent machinability. However, pure aluminum often fails to meet specific requirements for color and performance in certain situations. Therefore, anodizing has become an important surface treatment technology, providing a wide range of color choices for aluminum CNC machined parts while enhancing their corrosion resistance and durability.

66

66

Read more

Read more

VMT

VMT  2024 05 25

2024 05 25 Copper plating, as an important metal surface treatment technology, has a history dating back to the 19th century. Its principle is based on electrochemical reactions, where copper ions in an electrolyte solution are reduced to solid copper on the cathodic metal surface under the influence of an external electric current, forming a uniform and dense copper film. Copper plating technology is widely used not only in industrial fields but also in daily life and art production.

66

66

Read more

Read more

VMT

VMT  2024 05 24

2024 05 24 In the field of CNC machining parts manufacturing, titanium and aluminum are common metal materials. Each has its unique physical and chemical properties suitable for different applications. This article will provide a detailed comparison of the performance of titanium and aluminum to help you make the right choice for your project requirements.

66

66

Read more

Read more

VMT

VMT  2024 05 23

2024 05 23 Plastic extrusion, also known as extrusion molding or extrusion, is a critical technology in the field of plastic processing. It involves the interaction of plastic raw materials through an extruder barrel and screw, where they are heated and plasticized under the action of heat and shear forces. Subsequently, they are pushed by the screw to the die head, continuously forming various cross-sectional shapes of products or semi-finished products.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!