15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 05 22

2024 05 22 With the rapid advancement of robotics technology, the industry for machining robot parts has encountered unprecedented development opportunities. Precision CNC machining technology, as one of the core technologies for manufacturing robot parts, not only enhances the precision and efficiency of robot parts processing but also provides strong assurance for the overall performance improvement of robots. This article will introduce the top 10 manufacturers and suppliers for machining robot parts and explore the application of precision CNC machining technology in robot parts manufacturing.

66

66

Read more

Read more

VMT

VMT  2024 05 21

2024 05 21 In the field of CNC machining parts manufacturing, aluminum alloys are highly favored for their lightweight, corrosion resistance, and excellent mechanical properties. Among them, 6061 and 7075 aluminum alloys are two commonly used materials. However, due to their different chemical compositions, mechanical properties, and machining characteristics, choosing the appropriate aluminum alloy material is crucial for the success of your project. This article will provide a detailed overview of the characteristics, differences, applications, and selection methods of 6061 and 7075 aluminum alloys, helping readers better understand these two materials and make informed decisions for their projects.

66

66

Read more

Read more

VMT

VMT  2024 05 20

2024 05 20 In the field of CNC machined parts manufacturing, aluminum, as a lightweight and high-strength metal material, is widely used in aerospace, automotive, electronics, and other industries. However, aluminum surfaces often exhibit roughness and irregularities, necessitating surface treatment processes such as polishing to improve surface smoothness and aesthetics.

66

66

Read more

Read more

VMT

VMT  2024 05 19

2024 05 19 With the rapid advancement of aerospace technology, the aerospace component machining industry has encountered unprecedented opportunities for development. This article delves into the 13 outstanding enterprises and suppliers in the aerospace component machining manufacturing field over the past decade, analyzing various aspects of aerospace component machining processes and the remarkable performance of these enterprises in this field.

66

66

Read more

Read more

VMT

VMT  2024 05 18

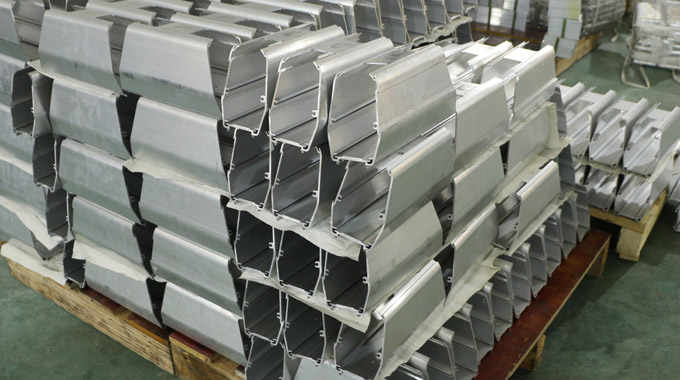

2024 05 18 In the field of CNC machining, the aluminum extrusion process has garnered significant attention due to its high precision and efficiency. As a crucial metal forming technology, aluminum extrusion profoundly impacts the manufacturing of aluminum profiles. This article provides a comprehensive breakdown of the aluminum extrusion process, including the definition of aluminum extrusion, direct and indirect extrusion processes, process steps, achievable shapes, influencing factors, and widespread applications of aluminum profiles. It also explores the pivotal role of aluminum extrusion in CNC machining.

66

66

Read more

Read more

VMT

VMT  2024 05 17

2024 05 17 In the field of CNC machining part manufacturing, metal plating surface treatment is a crucial technology that can improve the surface performance of metal parts, enhancing their corrosion resistance, wear resistance, aesthetics, and conductivity. This article provides a comprehensive overview of metal plating surface treatment, including its basic principles, steps, common types, advantages and disadvantages, applications, and considerations, aiming to help readers choose the most suitable plating process for their custom parts.

66

66

Read more

Read more

VMT

VMT  2024 05 16

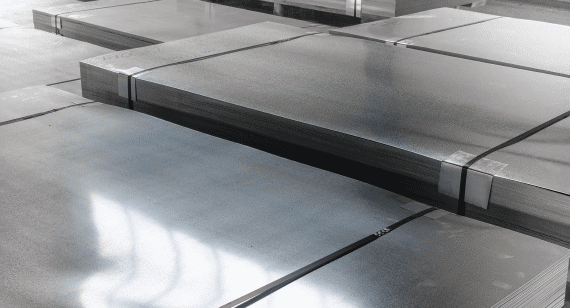

2024 05 16 In the field of CNC machining parts manufacturing, cast iron and steel are two common metal materials, each with unique physical and chemical properties, widely used in various industrial projects. This article provides a comprehensive introduction to cast iron and steel, comparing their differences and respective advantages and disadvantages in order to assist readers in making the right material choices for their projects.

66

66

Read more

Read more

VMT

VMT  2024 05 15

2024 05 15 In the field of CNC machining parts manufacturing, titanium and steel, as two common metal materials, are widely used in various industrial projects due to their unique physical and chemical properties. This article provides a comprehensive overview of titanium and steel, and delves into a detailed comparison of their differences in terms of elemental composition, weight, hardness, elasticity, durability, tensile yield strength, common applications, and pricing, aiming to assist readers in making the right choice for their projects.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!