15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 05 14

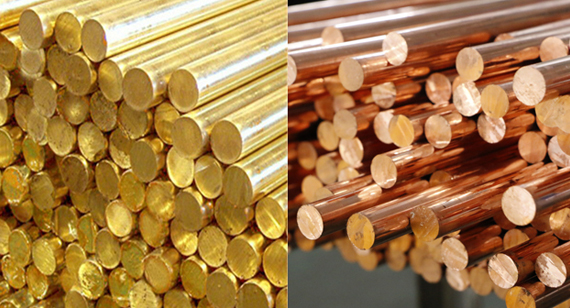

2024 05 14 Brass and bronze, common metal materials in the field of CNC machining, each have their own characteristics. This article will provide a comprehensive and detailed comparison of brass and bronze, analyzing their differences in material properties, conductivity, strength, formability, appearance and texture, pricing, and applications. The aim is to assist readers in making the correct choice during the manufacturing process of CNC machined parts.

66

66

Read more

Read more

VMT

VMT  2024 05 13

2024 05 13 This article delves into the applications and advantages of two CNC machining technologies, etching, and laser engraving, in part manufacturing. It compares and analyzes their differences, providing guidance on selecting the appropriate method. Additionally, the article explores the application areas of etching and laser engraving, showcases VMT CNC Machining Factory's manufacturing capabilities, and addresses common questions.

66

66

Read more

Read more

VMT

VMT  2024 05 12

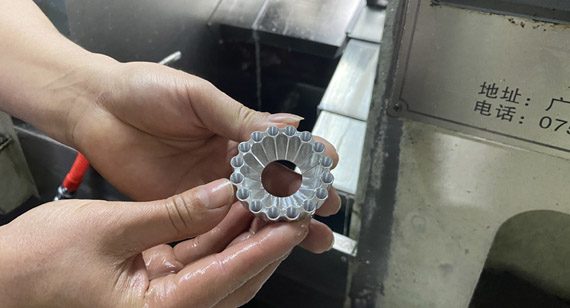

2024 05 12 This article aims to delve into the application and advantages of copper materials in automotive radiators, and elucidate the pivotal role of CNC machining processes in copper material processing. Through this article, readers will gain insights into the unique position of copper materials in automotive radiator design, as well as how CNC machining factories utilize their professional expertise to provide high-quality copper CNC machining parts and CNC machining services for the automotive industry.

66

66

Read more

Read more

VMT

VMT  2024 05 11

2024 05 11 The marine environment imposes high demands on material performance due to its unique physical, chemical, and biological characteristics. Copper materials have been widely used in marine environments due to their excellent corrosion resistance, thermal conductivity, and machinability. This article will discuss the application, advantages, corrosion issues, and protective measures of copper materials in marine environments.

66

66

Read more

Read more

VMT

VMT  2024 05 10

2024 05 10 The journey from prototype design to CNC machining production in the realm of CNC machined parts manufacturing is a complex and intricate process. This article provides a detailed analysis of this process, aiding readers in comprehending how to efficiently and accurately realize the transition from concept to physical entity, while also addressing common challenges encountered along the way.

66

66

Read more

Read more

VMT

VMT  2024 05 09

2024 05 09 With the rapid development of modern industry, die casting technology plays a crucial role in manufacturing. Zinc die casting, as an important branch of die casting technology, has been widely used in multiple fields due to its unique advantages. This article will provide a detailed analysis of the definition, material selection, advantages and disadvantages, applications of zinc die casting, as well as addressing common issues related to zinc alloy die casting parts, aiming to offer readers a comprehensive and in-depth understanding.

66

66

Read more

Read more

VMT

VMT  2024 05 08

2024 05 08 In the field of aluminum alloy materials, 6061 aluminum and 7075 aluminum play important roles in the manufacturing of CNC machined parts due to their unique physical and chemical properties. This article will conduct an in-depth comparison of these two aluminum alloy materials, covering aspects such as alloy overview, differences, chemical composition, mechanical properties, manufacturing considerations, applications, selection criteria, and common machining issues, aiming to provide readers with a comprehensive understanding and reference.

66

66

Read more

Read more

VMT

VMT  2024 05 07

2024 05 07 In the medical field, commonly used materials include medical polymers, medical metals, medical ceramics, and biocompatible materials. These materials play crucial roles in the manufacturing of medical instruments and devices due to their unique properties and advantages.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!