15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 04 20

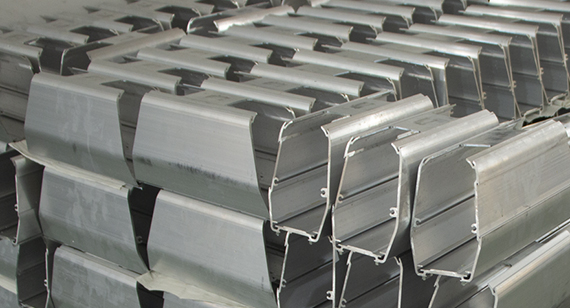

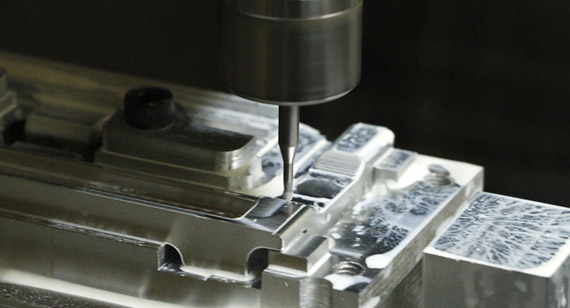

2024 04 20 In the field of CNC machining, CNC aluminum shell machining is a crucial process, but the common issue of profile lines during machining can be troublesome. Profile lines not only affect the aesthetics of the aluminum shell but also potentially impact its performance and accuracy. This article will delve into the causes of profile lines in CNC aluminum shell machining and propose effective removal methods to meet the demand for high-precision, high-quality CNC machined parts in machining factories.

66

66

Read more

Read more

VMT

VMT  2024 04 19

2024 04 19 In CNC machining factories, the introduction of turning-milling composite machines has brought numerous advantages to part manufacturing. As an outstanding representation of modern CNC machining technology, these machines integrate turning and milling functions, greatly enhancing production efficiency, machining accuracy, and flexibility. This article will delve into the benefits of CNC machining factories having turning-milling composite machines and discuss around key terms like CNC turning-milling, CNC machining factories, and CNC turning parts.

66

66

Read more

Read more

VMT

VMT  2024 04 18

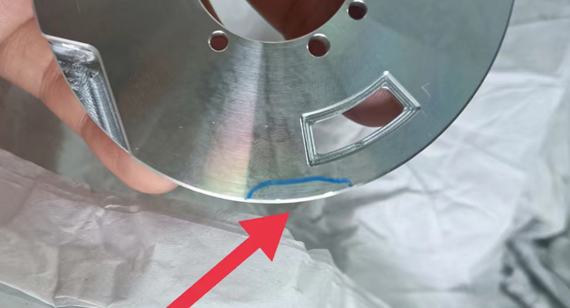

2024 04 18 In the field of precision parts CNC machining, preventing collisions and scratches during part processing has always been a key issue that CNC machining factories need to focus on and address. Collisions and scratches not only affect the appearance quality of parts but may also damage their performance and accuracy, leading to product defects or even scrap. Therefore, CNC machining factories need to take a series of measures to prevent collisions and scratches from occurring.

66

66

Read more

Read more

VMT

VMT  2024 04 17

2024 04 17 In the field of precision parts CNC machining, stress relief of materials is a crucial step. By alleviating stress, not only can the quality and performance of the parts be enhanced, but their lifespan can also be prolonged. This article delves into the benefits of material stress relief in precision parts CNC machining and elucidates its significance in practical applications.

66

66

Read more

Read more

VMT

VMT  2024 04 16

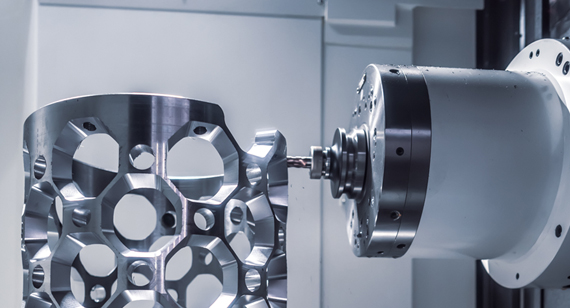

2024 04 16 With the rapid advancement of technology, robot technology, as a critical pillar of modern manufacturing, places high demands on the precision and quality of its components. CNC machining technology, known for its high precision and efficiency, plays an irreplaceable role in the manufacturing of robot parts. This article delves into the specific robot parts that are CNC machined, elucidating the advantages and applications of CNC machining in the production of these components.

66

66

Read more

Read more

VMT

VMT  2024 04 15

2024 04 15 As aerospace technology advances rapidly, the demands for precision and performance in components have escalated. CNC machining technology, as one of the core technologies in modern manufacturing, plays a pivotal role in the aerospace component manufacturing sector. This article delves into the topic of CNC machining aerospace components, discussing eight key points to be mindful of during the machining process. The aim is to assist CNC machining factories in enhancing machining quality to meet the high standards required in the aerospace industry.

66

66

Read more

Read more

VMT

VMT  2024 04 14

2024 04 14 In the realm of CNC precision parts machining, the success rate of prototyping directly impacts product quality, production efficiency, and customer satisfaction. However, when precision parts fail to meet specifications after multiple prototyping attempts, CNC precision parts machining factories need to delve into the underlying issues and take effective measures to address them.

66

66

Read more

Read more

VMT

VMT  2024 04 13

2024 04 13 In the realm of precision CNC machining part manufacturing, cost control and pricing strategy are pivotal for the survival and growth of CNC machining factories. Recently, there has been a phenomenon observed in the market: products with material costs of 4 yuan, polishing costs of 2.5 yuan, and oxidation costs of 3.5 yuan are being sold at a price of 11 yuan. This has sparked deep discussions within the industry regarding CNC machining costs and pricing strategies. This article will analyze this issue from a professional perspective and explore rational pricing methods for CNC machining parts.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!