15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 04 12

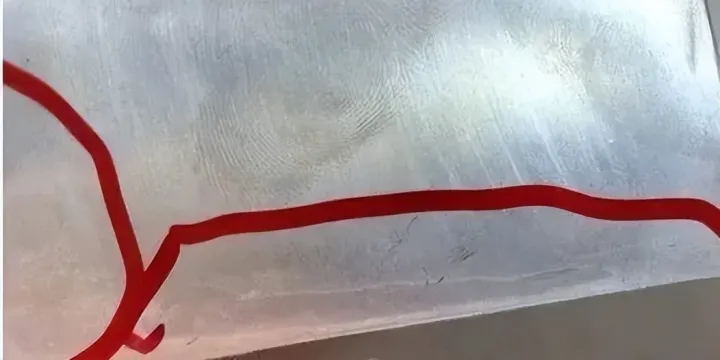

2024 04 12 In the realm of precision CNC machining part manufacturing, blade marks have long been a critical factor affecting product quality and production efficiency. However, even with tooling changes, program modifications, and the adoption of brand-new CNC machines, the issue of blade marks can sometimes persist. This article delves into the underlying reasons behind this phenomenon, providing tailored solutions for CNC machining factories.

66

66

Read more

Read more

VMT

VMT  2024 04 11

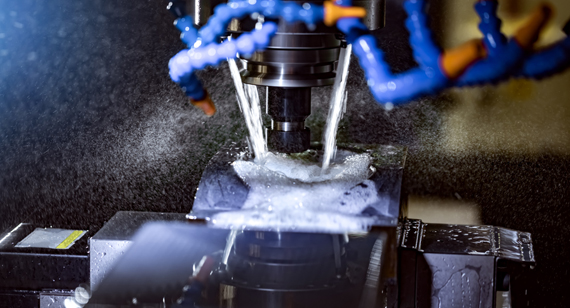

2024 04 11 In the realm of CNC machining part manufacturing, 5-axis CNC machining technology has garnered widespread attention for its efficient and high-precision machining capabilities. This article aims to delve into the composition and influencing factors of the service charges for 5-axis CNC machining parts, assisting you in selecting relevant services.

66

66

Read more

Read more

VMT

VMT  2024 04 10

2024 04 10 As manufacturing industries continue to evolve, CNC machining of precision parts has become an indispensable aspect of modern industrial processes. Particularly in the machining of box-type parts, the application of CNC technology is crucial. When machining box-type precision parts in CNC machining factories, strict adherence to a series of machining method considerations is essential to ensure the accuracy, quality, and production efficiency of the parts.

66

66

Read more

Read more

VMT

VMT  2024 04 09

2024 04 09 In the realm of CNC machining, chamfering of precision parts stands as a crucial process. Chamfering not only influences the aesthetic quality of parts but also directly impacts their assembly performance, lifespan, and safety. Therefore, in the CNC machining of precision parts, meticulous attention must be paid to chamfering to ensure that every detail meets design requirements.

66

66

Read more

Read more

VMT

VMT  2024 04 08

2024 04 08 In the field of CNC machining, surface treatment, especially the formation of oxide films, plays a crucial role in enhancing the corrosion resistance, wear resistance, and aesthetics of parts. However, the color and stability of oxide films are often influenced by various factors, leading to poor surface quality of parts.

66

66

Read more

Read more

VMT

VMT  2024 04 07

2024 04 07 In the realm of CNC machining, encountering tool engagement issues and tolerance deviations is common when utilizing 4-axis machines for precision CNC component fabrication. These issues not only impact machining efficiency but also directly affect the quality and performance of the components.

66

66

Read more

Read more

VMT

VMT  2024 04 06

2024 04 06 In the realm of CNC machining, optimizing machining processes is crucial for ensuring the quality of precision components with stringent flatness requirements. However, beyond process refinement, stress relief treatment also significantly influences the final accuracy and flatness of components.

66

66

Read more

Read more

VMT

VMT  2024 04 05

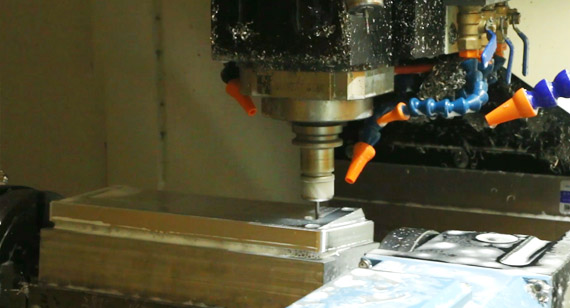

2024 04 05 In the process of manufacturing precision CNC machined parts, the application of CNC machining equipment is both widespread and critical. However, sometimes surface tool marks can occur during part machining, impacting not only aesthetics but also potentially the performance and accuracy of the parts. When faced with such issues, many initially question whether the tool selection was incorrect. However, in reality, the causes of tool marks in CNC machining can be diverse, with tool selection being just one factor.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!