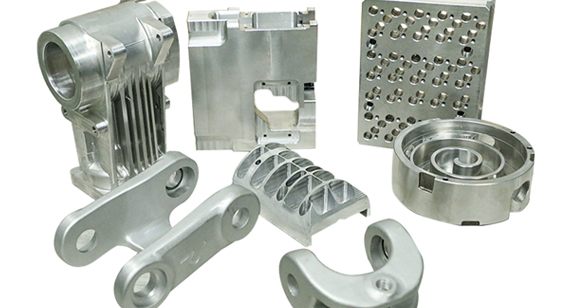

15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 04 28

2024 04 28 In modern manufacturing, CNC machining services have become a crucial force driving industrial upgrading and innovation due to their advantages of high precision, efficiency, and flexibility. Customization capability, as a major feature of CNC machining services, meets the market demand for personalized and diversified products. This article will delve into the customization capability provided by CNC machining services, exploring its implementation mechanism, advantages, and future development prospects.

66

66

Read more

Read more

VMT

VMT  2024 04 27

2024 04 27 In the field of CNC machining part manufacturing, precision CNC machined parts have garnered attention for their high precision, quality, and efficiency. Tolerance, as a crucial indicator of machining accuracy, is particularly important for precision CNC machined parts. So, what is the minimum tolerance achievable for precision CNC machined parts? This article will delve into this topic, providing readers with in-depth professional knowledge.

66

66

Read more

Read more

VMT

VMT  2024 04 26

2024 04 26 In the field of CNC machining part manufacturing, there are significant differences between precision CNC machined parts and regular CNC machined parts in several aspects. These differences are not only reflected in machining accuracy, quality stability, and process complexity but also in machining equipment, programming difficulty, production efficiency, and many other dimensions. This article will delve into the differences between precision CNC machined parts and regular CNC machined parts from these aspects.

66

66

Read more

Read more

VMT

VMT  2024 04 25

2024 04 25 With the continuous advancement of industrial manufacturing technology worldwide, the field of CNC machining, as an integral part of the manufacturing industry, is experiencing unprecedented opportunities for development. Among them, precision CNC machining parts have become the core driving force for industrial upgrading. This article will introduce the top 10 CNC machining parts manufacturing services globally. These factories provide high-quality precision CNC machining parts to global customers through their excellent CNC machining technology, efficient production capacity, and superior services.

66

66

Read more

Read more

VMT

VMT  2024 04 24

2024 04 24 In the field of CNC machining parts manufacturing, the production of precision CNC machining parts undoubtedly holds a significant position. These parts have stringent requirements for precision, surface quality, and machining efficiency, often leading to various challenges during the machining process. As experts in CNC machining parts manufacturing, this article will delve into the common challenges encountered during the production of precision CNC machining parts and analyze their causes and solutions.

66

66

Read more

Read more

VMT

VMT  2024 04 23

2024 04 23 In the process of product development, prototype CNC machining plays a pivotal role. It not only helps designers validate the feasibility of product designs but also provides crucial process parameters and references for subsequent mass production. As an expert in the field of CNC machined parts manufacturing, I will delve into the specific roles of prototype CNC machining in the product development process.

66

66

Read more

Read more

VMT

VMT  2024 04 22

2024 04 22 In the field of CNC machining, the hardness of parts is a crucial indicator directly related to their performance, lifespan, and safety. Therefore, understanding and mastering the factors that affect the hardness of CNC machined parts is of paramount importance for CNC machining manufacturers. This article will delve into the main factors determining the hardness of CNC machined parts, aiming to provide readers with comprehensive and in-depth knowledge.

66

66

Read more

Read more

VMT

VMT  2024 04 21

2024 04 21 In the field of CNC machining, machining optical precision components has always been a challenge and focus due to their special requirements for high precision and surface quality. After completing a series of complex machining processes, testing the material hardness becomes an indispensable step. This article will delve into the reasons why measuring material hardness is necessary after machining optical precision components from multiple perspectives, aiming to meet the professional knowledge needs of CNC machining factories and related practitioners for manufacturing high-precision, high-quality CNC machined parts.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!