15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 06 07

2024 06 07 Steel and stainless steel hold significant importance in CNC machined parts manufacturing. Understanding their differences is crucial for selecting the appropriate material. This article compares them in terms of composition, mechanical properties, corrosion resistance, heat treatment and manufacturing, applications, cost, and environmental considerations.

66

66

Read more

Read more

VMT

VMT  2024 06 06

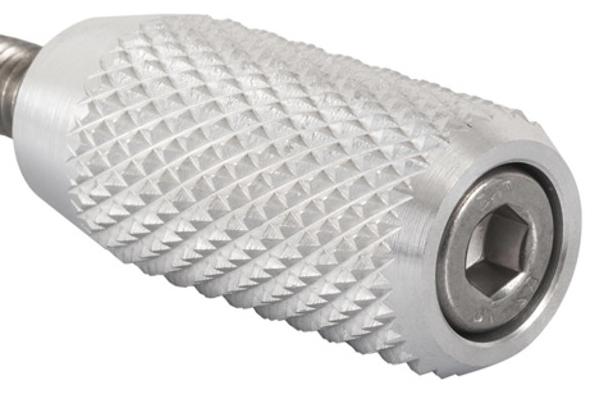

2024 06 06 Knurling is a machining process that creates specific textures or patterns on the surface of metals, plastics, or other materials. This process involves rolling a knurling tool over the material’s surface, where the tool's texture or pattern imprints onto the material. Widely used across various manufacturing industries, knurling typically produces cross-hatched or diamond-shaped patterns, enhancing the product's aesthetics, improving anti-slip properties, or fulfilling specific functional requirements.

66

66

Read more

Read more

VMT

VMT  2024 06 05

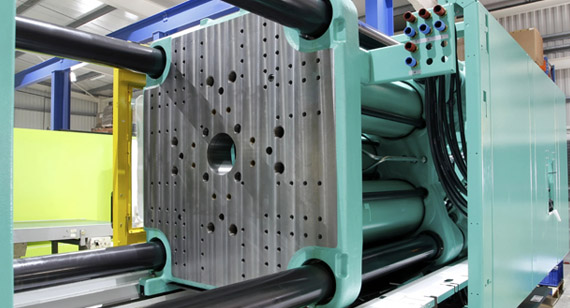

2024 06 05 In the field of CNC machined parts manufacturing, injection molding and extrusion molding are two commonly used plastic forming techniques. Despite their shared goal of transforming plastic into desired parts, they differ significantly in several aspects.

66

66

Read more

Read more

VMT

VMT  2024 06 04

2024 06 04 This article comprehensively explores the application of nylon materials in the CNC machining field, providing an in-depth analysis of the properties, types, advantages, and disadvantages of nylon (polyamide) materials, as well as common issues that may arise in practical applications. And discuss the process selection of nylon CNC machining parts.

66

66

Read more

Read more

VMT

VMT  2024 06 03

2024 06 03 CNC machining and injection molding are two crucial manufacturing methods, each differing in material selection, machining precision, production volume, and more. When choosing a processing method, it is essential to consider product requirements, cost-effectiveness, and other relevant factors.

66

66

Read more

Read more

VMT

VMT  2024 06 02

2024 06 02 This article delves into the concept and types of heat treatment technology and its application in CNC aluminum machining parts. It thoroughly explores how heat treatment affects the hardness of CNC aluminum parts, aiming to provide technical reference and guidance for CNC machining workshops.

66

66

Read more

Read more

VMT

VMT  2024 06 01

2024 06 01 With the rapid development of aerospace technology, CNC (Computer Numerical Control) machining plays a crucial role in the manufacturing of aerospace parts. CNC machining technology meets the special requirements of aerospace parts manufacturing with its high precision, efficiency, and flexibility. This article explores eight key aspects of CNC machining for aerospace parts, providing readers with a comprehensive understanding.

66

66

Read more

Read more

VMT

VMT  2024 05 31

2024 05 31 Die casting and injection molding are two common molding processes, each with its unique advantages and applicable ranges. When choosing the appropriate process, it is essential to consider factors such as product material, shape, dimensional accuracy, production volume, and cost.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!