15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

138 |

Published by VMT at Feb 10 2024

138 |

Published by VMT at Feb 10 2024

In today's highly competitive market environment, ensuring the quality of parts has become a crucial factor for the survival and development of CNC machining factories. Quality is the lifeline of businesses, particularly in manufacturing, where high-quality parts form the cornerstone for product performance, customer satisfaction, and durability. This article explores how to ensure the quality of parts in a CNC machining factory.

1. Strict Control of Raw Material Quality

The quality of raw materials directly impacts the final quality of parts. Therefore, choosing reliable suppliers and conducting quality checks on the provided raw materials is crucial. When possible, perform chemical, physical, and mechanical property tests on raw materials to ensure they meet design requirements and process standards.

2. Advanced Machining Equipment and Processes

High-precision CNC machining equipment is the foundation for manufacturing high-quality parts. Ensure that equipment is in good working condition, conduct regular maintenance and calibration to guarantee the required geometric and positional accuracy during the machining process. Additionally, adopting advanced machining processes such as high-speed cutting and precision machining can further enhance surface quality and processing efficiency.

3. Optimization of CNC Programs and Tool Paths

A rational CNC program and tool paths are critical for ensuring part machining quality and efficiency. By optimizing cutting parameters, selecting suitable tools and cutting fluids, and utilizing CAM software for precise simulated machining, it is possible to effectively reduce machining defects and errors, improving part machining accuracy.

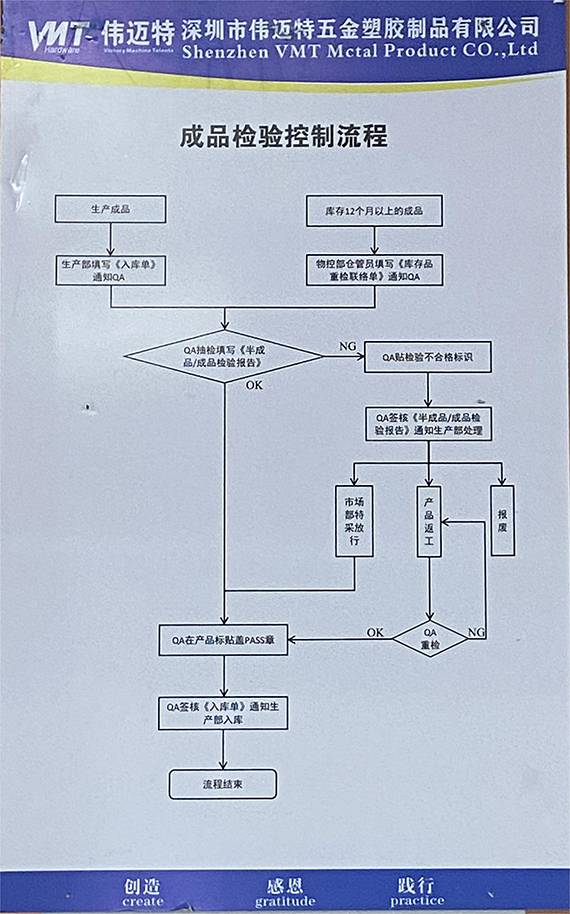

4. Establishment of a Comprehensive Quality Management System (QMS)

A Quality Management System (QMS) serves as the foundational infrastructure for ensuring part quality. Develop detailed quality plans, standards, and inspection procedures, clearly define responsibilities and workflows for each department, and ensure comprehensive quality control throughout the entire process from raw material receipt to final product shipment. Additionally, implement regular internal and external audits to ensure system effectiveness and compliance.

5. Employee Training and Cultivation of Quality Awareness

Employees are the core force on the production front. Conduct regular skill training and quality management training for employees to equip them with advanced process technologies and quality management methods, thereby enhancing production efficiency and product quality. Simultaneously, cultivate employees' quality awareness and sense of responsibility to uphold the principle of quality first throughout the production process.

6. Continuous Improvement and Innovation

Quality is not static; it requires continuous improvement and innovation. Analyze data from the production process, identify problems, and opportunities for improvement, develop targeted improvement measures, and put them into practice. Additionally, stay attuned to industry trends and technological innovations, introducing new technologies and methods into the production process to enhance part quality and production efficiency.

7. Close Communication and Collaboration with Customers

Customer needs and feedback are crucial sources of information for improving part quality. Maintain close communication and collaboration with customers to promptly understand market dynamics and changes in customer requirements. Tailor improvements to products and service quality accordingly. Participate in customer product development processes, provide technical support and advice, and jointly achieve the goal of manufacturing high-quality parts.

8. Strict Control of Delivery Schedules

Delivery schedules are vital indicators of CNC machining factory production efficiency. While ensuring part quality, schedule production plans reasonably to ensure on-time delivery. Transparent communication with customers is essential; if there are any delays, inform the customer promptly and explain the reasons. Maximize customer satisfaction by effective production management and resource scheduling to meet delivery schedule requirements.

9. After-Sales Tracking and Continuous Improvement

After-sales tracking is a crucial aspect of understanding how parts perform in actual use. Establish a comprehensive after-sales tracking system, collect feedback from customers, analyze problems, and identify improvement needs during the product's usage. Use this feedback as a basis for continuous product improvement, enhancing part quality, and customer satisfaction.

Conclusion:

Ensuring the quality of parts in a CNC machining factory is a systematic and comprehensive process. From strict control of raw material quality to the application of advanced equipment and processes, from the establishment of a quality management system to employee training and continuous improvement, each step is indispensable. Close communication and collaboration with customers are also key to enhancing quality. By comprehensively applying these measures, CNC machining factories can manufacture high-quality parts, earning the trust of customers and maintaining competitiveness in the market.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!