15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2023 10 03

2023 10 03 Achieving complex curved surfaces and multi-axis machining in aluminum CNC machining demands a combination of advanced equipment, software, tooling, and expertise. It's essential to collaborate closely with CNC programmers and machinists to ensure the successful production of parts with intricate contours and high precision.

66

66

Read more

Read more

VMT

VMT  2023 10 02

2023 10 02 By following these steps and adopting a holistic approach to precision machining, you can maintain tight tolerances of 0.01mm and ensure consistent part quality. Consistency is achieved through a combination of design considerations, equipment, processes, and quality control measures.

66

66

Read more

Read more

VMT

VMT  2023 10 01

2023 10 01 For parts manufactured using CNC machining, it's crucial to consider the characteristics of CNC processes during the design phase. This ensures that while maintaining machining efficiency and quality, you also aim to minimize the machining costs. Here are some universally applicable design optimization strategies

66

66

Read more

Read more

VMT

VMT  2023 09 30

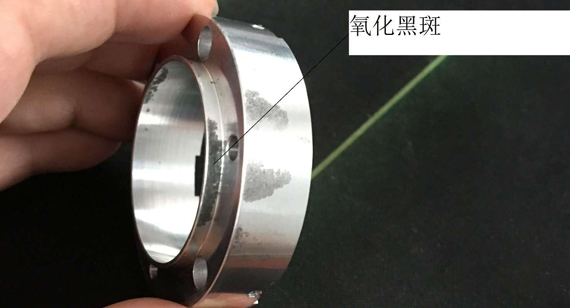

2023 09 30 The appearance of black spots or streaks on 7075 aluminum after CNC machining can be attributed to various factors. Here are some potential reasons for black spot formation on CNC machined 7075 aluminum

66

66

Read more

Read more

VMT

VMT  2023 09 29

2023 09 29 In order to avoid the above 3 bad causes, the PH value of the cutting fluid should be tested regularly. At the same time, the CNC aluminum alloy parts sent to the oxidation plant should not be left for more than 7 days, especially when the weather is hot. In addition, the conditions of the oxidation process must be monitored. , can effectively prevent the sand hole defects caused by oxidation after CNC machining.

66

66

Read more

Read more

VMT

VMT  2023 09 28

2023 09 28 In the process of product development and design, the structural design of the product is crucial. It not only influences whether the product can be realized but also plays a significant role in determining the cost. Many design companies tend to focus solely on external aesthetics, neglecting the intricacies of structural design, which can lead to high design costs and increased production costs.

66

66

Read more

Read more

VMT

VMT  2023 09 27

2023 09 27 These are just a few examples of the diverse range of shapes and geometries that can be manufactured through CNC machining. The versatility and precision of CNC technology make it suitable for a wide array of industries and applications, accommodating various part shapes and sizes.

66

66

Read more

Read more

VMT

VMT  2023 09 26

2023 09 26 The choice of inspection methods depends on the specific requirements of the CNC machined part and the industry standards it must adhere to. It's essential to communicate with your customers to understand their quality expectations and tailor the inspection process accordingly to deliver high-quality CNC machined parts.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!