15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2023 09 17

2023 09 17 Nickel plating, also known as nickel electroplating, is a surface finishing process that involves depositing a layer of nickel onto the surface of a metal or other substrate. This electrochemical process is used to enhance the appearance, corrosion resistance, and wear resistance of the coated object. Nickel plating can be applied to a wide range of materials, including steel, brass, copper, and even plastics.

66

66

Read more

Read more

VMT

VMT  2023 09 16

2023 09 16 Blue zinc plating, often referred to as blue zinc passivation, is a type of electroplating process used to apply a layer of zinc onto the surface of steel or iron components. The "blue" in blue zinc plating refers to the color of the passivation coating that is applied on top of the zinc layer.

66

66

Read more

Read more

VMT

VMT  2023 09 15

2023 09 15 Electrocoating, commonly known as e-coating or electro deposition coating, is a method of applying a protective or decorative coating to a metal object through an electrochemical process. It is used to provide corrosion resistance, enhance aesthetics, and improve the durability of metal parts.

66

66

Read more

Read more

VMT

VMT  2023 09 14

2023 09 14 Water transfer printing, also known as hydrographic printing or hydro dipping, is a surface decoration process used to apply intricate and detailed patterns or designs onto three-dimensional objects. This technique involves transferring a printed design from a water-soluble film onto the surface of an object, typically made of materials like plastics, metals, ceramics, or composite materials.

66

66

Read more

Read more

VMT

VMT  2023 09 13

2023 09 13 Powder coating brass refers to the process of applying a dry powder coating material to the surface of brass objects or components. This coating material is typically a mixture of finely ground particles of pigment and resin. The process involves electrostatically charging the powder particles and then applying them to the grounded brass surface. Once the powder is evenly distributed on the brass, the object is heated in an oven. During the curing process, the powder melts, flows, and forms a continuous, durable, and protective coating on the brass surface.

66

66

Read more

Read more

VMT

VMT  2023 09 12

2023 09 12 Powder coating is a versatile and environmentally friendly method of applying a protective finish to various products. Unlike traditional liquid paint, which is solvent-based, powder coating involves the application of a dry, free-flowing powder to the surface of an object. This powder is then heat-cured to create a hard, durable, and attractive finish.

66

66

Read more

Read more

VMT

VMT  2023 09 11

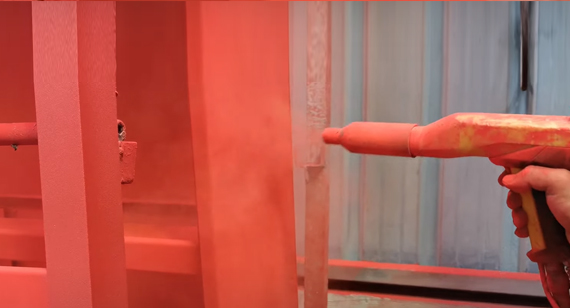

2023 09 11 Spray painting, often simply referred to as "paint spraying" or "spray coating," is a method of applying a liquid paint or coating onto a surface using a specialized device called a spray gun or paint sprayer. This technique is commonly used in various industries and applications for its efficiency and ability to achieve even, smooth, and consistent paint coverage.

66

66

Read more

Read more

VMT

VMT  2023 09 10

2023 09 10 Color Anodizing is a surface treatment process that enhances the appearance and performance of metals, typically aluminum. This method shares similarities with traditional anodizing but introduces vibrant colors to the metal's surface. Let's delve into what Color Anodizing is and explore its advantages and disadvantages.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!