15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2023 09 01

2023 09 01 Aluminum alloys are identified by a combination of numbers and letters that make up their alloy designation or grade. This system helps to categorize and describe the specific alloy composition and properties. Here's a breakdown of the typical aluminum alloy designation format.

66

66

Read more

Read more

VMT

VMT  2023 08 31

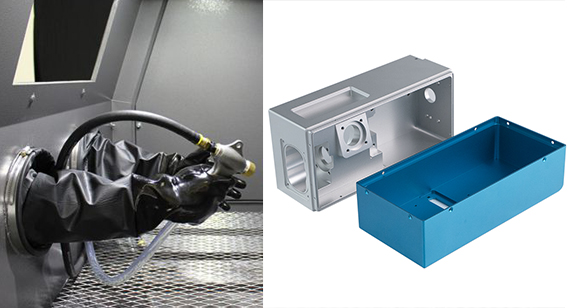

2023 08 31 Sandblasting, also known as abrasive blasting, involves propelling fine particles at high velocity onto a surface to alter its texture or prepare it for further treatment. This technique is widely used to remove rust, paint, and contaminants from surfaces. While sand was traditionally the abrasive medium, modern variations utilize various media like aluminum oxide, glass beads, and steel grit.

66

66

Read more

Read more

VMT

VMT  2023 08 30

2023 08 30 6061 aluminum alloy is a versatile and widely used material known for its excellent combination of strength, corrosion resistance, and machinability. It belongs to the 6xxx series of aluminum alloys, which are often referred to as "structural alloys" due to their suitability for various structural applications.

66

66

Read more

Read more

VMT

VMT  2023 08 29

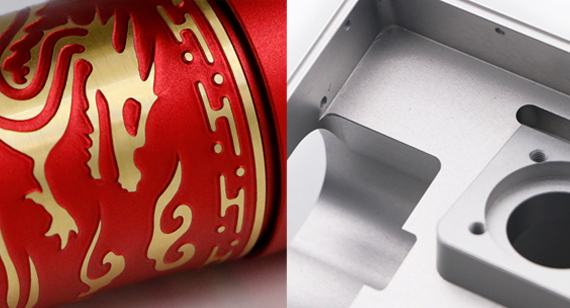

2023 08 29 Custom aluminum fabrication refers to the intricate process of shaping, manipulating, and assembling aluminum materials into finished products or components. This versatile metal's lightweight nature, corrosion resistance, and malleability make it a preferred choice for a wide range of applications across industries.

66

66

Read more

Read more

VMT

VMT  2023 08 28

2023 08 28 Metal polishing is a surface finishing process that involves the removal of imperfections, scratches, and roughness from metal surfaces to achieve a smooth, reflective, and aesthetically pleasing appearance. This technique enhances the surface quality of metals while also improving their corrosion resistance and cleanliness. Metal polishing is utilized across various industries, including automotive, jewelry, electronics, and architecture, to elevate the aesthetics and functionality of metal components.

66

66

Read more

Read more

VMT

VMT  2023 08 25

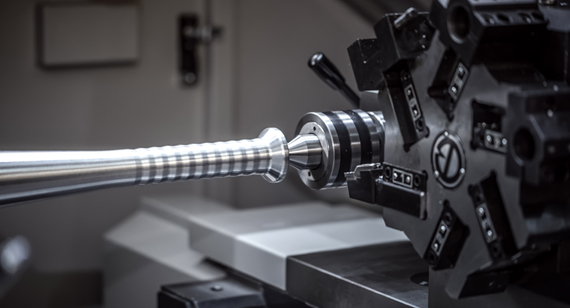

2023 08 25 In the precision machining parts, deep hole CNC machining is a special machining method for CNC machining deep holes. It is suitable for the situation that needs to be processed inside the workpiece, such as drilling, reshaping, slamming, etc. So, what exactly is deep hole machining?

66

66

Read more

Read more

VMT

VMT  2023 08 24

2023 08 24 Sandblasting is a widely used surface treatment method for aluminum due to its effectiveness in enhancing the material's appearance, texture, and performance. This article delves into the reasons why sandblasting is a popular choice for treating aluminum surfaces.

66

66

Read more

Read more

VMT

VMT  2023 08 23

2023 08 23 Etching is a surface treatment technique that involves selectively removing material from a substrate using chemical processes. This method is used to create intricate patterns, designs, and textures on various materials. While etching offers several advantages, it also comes with certain drawbacks that need to be considered.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!