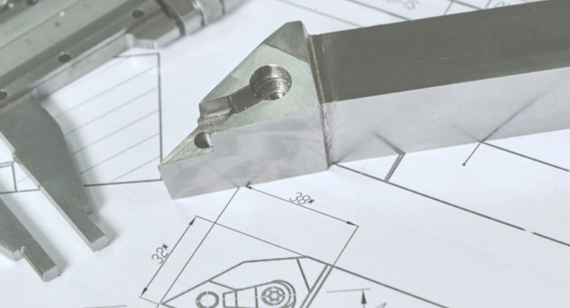

15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2023 05 13

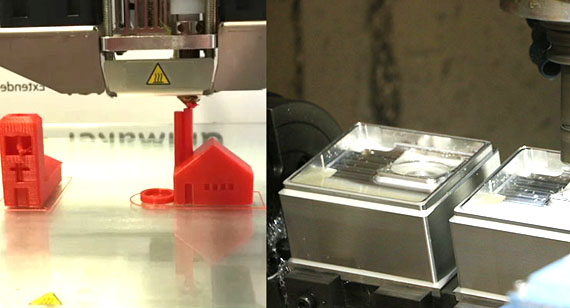

2023 05 13 CNC prototyping machining is the process of creating a physical prototype of a product or component using specialized equipment such as CNC (Computer Numerical Control) machines. It involves using a digital design or blueprint to create a 3D model of the product, which is then translated into machine code and used by the CNC machine to carve or cut the material into the desired shape.

66

66

Read more

Read more

VMT

VMT  2023 05 12

2023 05 12 CNC CNC prototype machining is a manufacturing process used to create a sample or prototype of a product. It typically uses computer-aided design (CAD) software and computer numerical control (CNC) machines to precisely cut and shape materials to create a model that resembles the final product. These prototypes can be used to test product design and performance and make necessary modifications and improvements.

66

66

Read more

Read more

VMT

VMT  2023 01 12

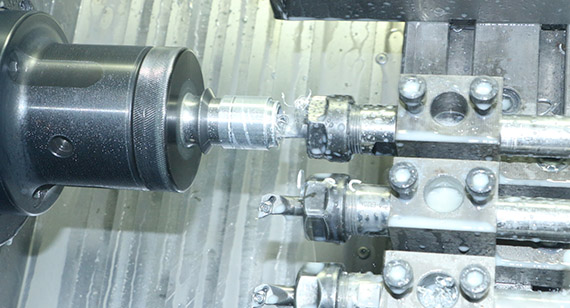

2023 01 12 Four standard threads of metric system, inch system, modulus and diameter control can be turned on the CNC lathe. No matter which kind of thread is turned, a strict motion relationship must be maintained between the lathe spindle and the tool: that is, each revolution of the spindle (that is, the workpiece One turn), the tool should move evenly by one lead (of the workpiece).

66

66

Read more

Read more

VMT

VMT  2023 01 11

2023 01 11 Curved surface parts and curved tooling tools are the types of workpieces that are very suitable for processing by machining centers. In the industrial field, curved surface parts are also widely used, such as turbine blades, ship propellers, industrial products with cylindrical and conical surfaces, and so on.

66

66

Read more

Read more

VMT

VMT  2023 01 10

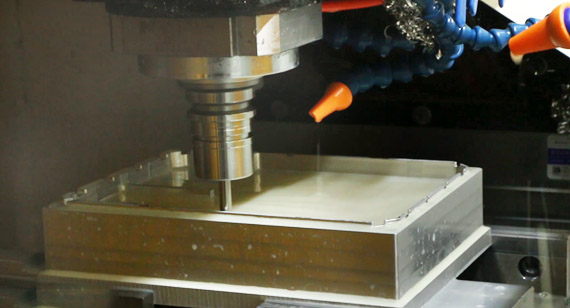

2023 01 10 CNC milling is a machining process that uses computer control and cutting tools to selectively remove material from a workpiece and produce custom-designed parts. A CNC milling machine has a table that automatically moves (or rotates) the workpiece in different planes so that the tool can work on it.

66

66

Read more

Read more

VMT

VMT  2023 01 09

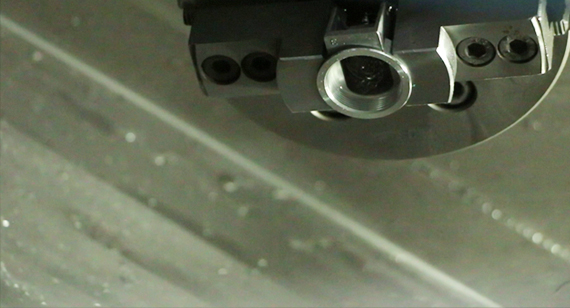

2023 01 09 A thread is a continuous protrusion and groove formed along a helix on a cylindrical or conical surface with the same cross-section and specified profile. Among various mechanical products, threaded parts are widely used. It is mainly used as connecting parts, fastening parts, transmission parts and measuring parts, etc.

66

66

Read more

Read more

VMT

VMT  2023 01 07

2023 01 07 Tolerance in CNC machining refers to the allowable variation of a parameter within a specific range. This parameter can be a variety of measurable physical properties such as temperature, humidity, noise level, stress, solar radiation rate and velocity, etc., or it can be a physical dimension, such as the size of the space.

66

66

Read more

Read more

VMT

VMT  2023 01 06

2023 01 06 Polyoxymethylene homopolymer (POM) is an impact and abrasion resistant semi-crystalline thermoplastic. Acetal (acetal), Polyoxymethylene (POM), Polyacetal (polyacetal), Polyformaldehyde, Saigang, these are its names, and the common ones are black and white. Despite being opaque in nature, POM is available in a variety of colors.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!